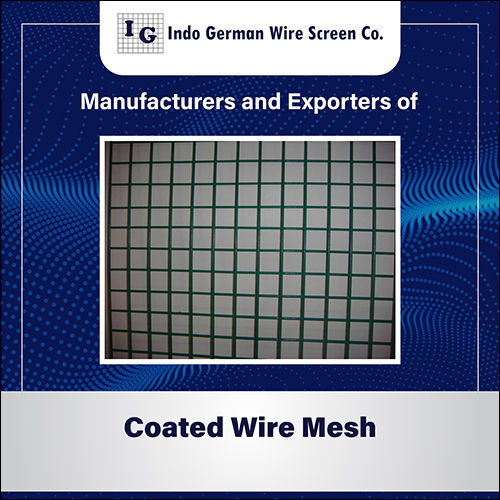

Coated Wire Mesh

Coated Wire Mesh Specification

- Wire Gauge

- Available in 24 to 10 gauge

- Surface Treatment

- Polished

- Hole Shape

- Square

- Length

- Standard rolls of 30 meters

- Aperture

- 12mm to 50mm

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Welded Mesh

- Material

- Low Carbon Steel

- Alloy

- Mild Steel

- Application

- Fencing, Industrial Filtration, Building Construction, Safety Guards

- Dimensions

- 1m x 30m, 1.2m x 30m

- Wire Diameter

- 0.5mm to 2mm

- Weight

- 4kg to 35kg per roll

- Color

- Black

- Corrosion Resistance

- High

- Fire Resistance

- Non-flammable coating

- Coating Type

- PVC Coated

- Temperature Resistance

- -30°C to 80°C

- Packing

- Rolls with Water-proof Paper

- Coating Thickness

- 0.3mm

- Edge Type

- Trimmed/Untrimmed

- Tensile Strength

- 350 to 550 MPa

- Usage

- Outdoor & Indoor

Coated Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Coated Wire Mesh

Coated Wire Mesh is used to make bird cages & fencings, applying as bird protection, and for other architectural applications as well. It is coated with superior quality PVC thermoplastic polymer which provides excellent resistance to moisture, corrosion, & external environmental conditions. This mesh is said to have ability to bear different climatic changes without any structural wear. It has glossy surface finish which remains intact for long period of time. Coated Wire Mesh offered by us is available in different dimensional & structural configurations at cost-effective rates for our trusted clients. It shows great deformation resistance and has high durability.

Special Features :

- This hexagonal wire mesh is available with double sided twisted or reverse twisted pattern,

- Available with PVC or galvanized coating

- Flat and uniform surface with oxidation proof design

- Precise wire diameter, stable structure, low maintenance cost, simple installation process and high strength

Product details

|

Hole Shape |

Square |

|

Usage |

Industrial |

|

Wire Gauge |

0.45-5.5mm |

|

Type |

Welded Mes |

Superior Coating for Extended Lifespan

Each mesh is enveloped in a 0.3mm thick PVC layer, guarding the underlying mild steel against moisture, corrosion, and everyday wear. This robust coating enhances the products longevity, even in demanding outdoor environments, while the polished surface ensures easy maintenance and a professional appearance.

Versatility in Application and Design

Choose from a selection of wire gauges, aperture sizes, and roll dimensions to suit fencing, safety guards, industrial filtration, or construction needs. The meshs strength (350 to 550 MPa) and non-flammable coating make it perfect for environments where both resilience and safety are critical.

Easy Handling, Installation, and Packaging

Supplied in compact rolls wrapped in water-proof paper, the mesh is simple to store, transport, and install. Both trimmed and untrimmed edge types are available, allowing effortless customization on-site for various projects.

FAQs of Coated Wire Mesh:

Q: How does the PVC coating enhance the performance and durability of the wire mesh?

A: The 0.3mm thick PVC coating acts as a protective barrier, preventing rust, corrosion, and chemical damage to the steel wire mesh. This feature ensures a longer lifespan and reliable performance, especially in outdoor and humid indoor conditions.Q: What are the recommended usage scenarios for this PVC coated wire mesh?

A: This mesh is ideal for fencing, safety guards, industrial filtration, and building construction. It is suitable for both interior and exterior environments due to its corrosion resistance, fire-safe coating, and broad temperature tolerance.Q: When is it advisable to choose trimmed versus untrimmed edge types?

A: Trimmed edges are recommended for applications requiring a clean, smooth finish, such as visible fencing or architectural features. Untrimmed edges can be used where aesthetics are less critical or further customization on site is planned.Q: Where can these wire meshes be installed, given their temperature and fire resistance properties?

A: The mesh can be safely used in a wide range of locations, from industrial sites and outdoor perimeters to building interiors, thanks to its -30C to 80C temperature resistance and non-flammable PVC coating.Q: What is the process for installing the mesh and what packing options are available?

A: Installation is straightforward: the mesh arrives in 30-meter rolls protected by water-proof paper, which ensures they remain dry and undamaged until use. The rolls can be easily uncoiled, cut to size, and attached using standard mounting hardware.Q: What are the key benefits of using mild steel in the manufacture of these meshes?

A: Mild steel provides a combination of high tensile strength (350 to 550 MPa), ductility, and cost-efficiency, making the mesh robust for security, filtration, and structural reinforcement while remaining easy to work with and economical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

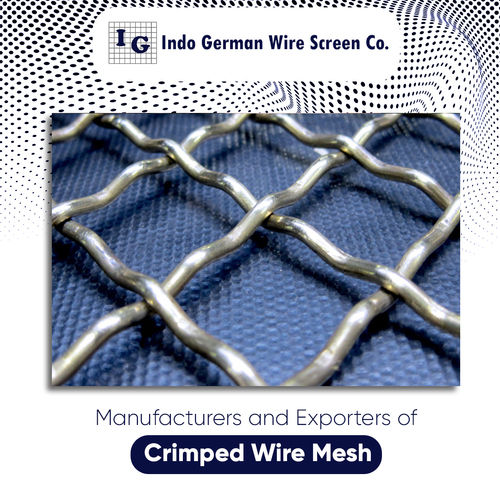

Crimped Wire Mesh

Price Range 150.00 - 190.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Steel

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

Color : Silver

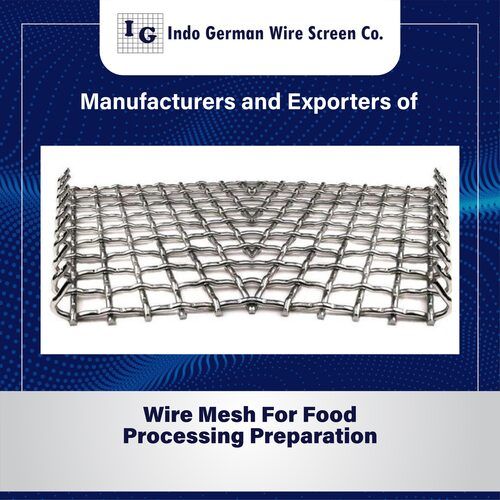

Wire Mesh For Food Processing and Preparation

Minimum Order Quantity : 50 Feet

Material : Steel

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

Color : Silver

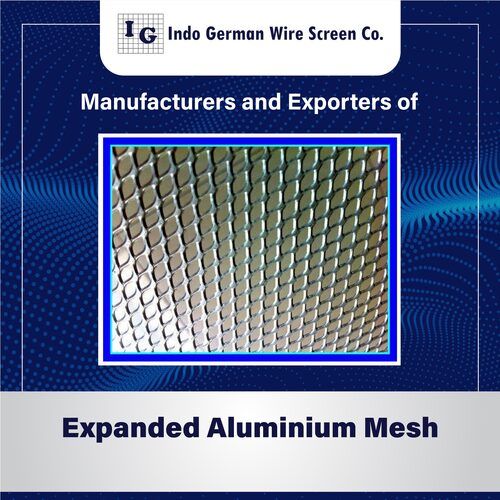

Expanded Aluminum Mesh

Price Range 18.00 - 30.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Material : Aluminum

Mesh Type : Aluminum Wire Mesh

Product Type : Wire Mesh

Color : Silver

Wire Jali

Price Range 9.00 - 15.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Galvanized Steel

Mesh Type : Galvanized Iron Wire

Product Type : Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry