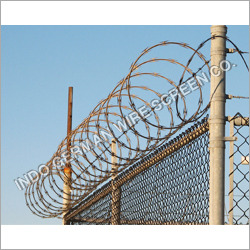

Concertina Wire

Concertina Wire Specification

- Length

- 6 - 10 meters (coil) or as required

- Aperture

- N/A (Spiral Rolls)

- Surface Treatment

- Plated

- Wire Gauge

- 12 to 14 SWG

- Hole Shape

- N/A (Spiral Rolls)

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Concertina Coil

- Material

- Stainless Steel

- Alloy

- AISI 304 or 316

- Application

- High Security Fencing, Border Security, Military and Industrial Security

- Dimensions

- 450 mm - 980 mm coil diameter

- Wire Diameter

- 2.5 mm - 3 mm

- Weight

- 7 - 11 kg per coil

- Color

- Silver

- Packing

- Roll/coil with waterproof wrapping

- Coil Type

- Spiral / Helical

- Installation Method

- Clamping or tying onto fences/walls

- Service Life

- 10-20 years (depends on environment)

- Blade Thickness

- 0.5 mm

- Corrosion Resistance

- High

- No. of Loops per Coil

- 45 - 56 loops

- Core Wire Tensile Strength

- 1200 - 1600 MPa

- Blade Type

- Standard BTO-22 (Barbed Tape Obstacle)

Concertina Wire Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

- Certifications

- Test Certification available at the time of dispatch.

About Concertina Wire

We are counted as a reliable Supplier, trader, importer, manufacturer and exporter of Concertina Wire. In order to fulfill the demands of our customers, we manufacture this wire using reliable raw materials and latest technology. This materials is thoroughly tested on various parameters. Apart from this, as per the requirements of the domain, we develop this Concertina Wire in a various of sharp-edged barbs, sizes and provided specifications. In addition, we offer this Concertina Wire to our customers at affordable prices.

Features:

- Sharp-edged barbs

- Available in various sizes

- Long shelf life

- Rust resistance

Technical Details:

| Coil Diameters (mm) | Coil Diameters (inches) | Spiral Turns per coil | Recommended Stretched Length (mtrs) | Clips per Spiral |

| 450mm | 18 inches | 50/51 | 8m to 10m | 3 |

| 610mm | 24 inches | 55/56 | 8m to 10m | 5 |

| 750mm | 30 inches | 55/56 | 8m to 10m | 5 |

| 900mm | 36 inches | 55/56 | 10m to 12m | 5 |

| 1050mm | 42 inches | 55/56 | 10m to 12m | 5 to 7 |

Enhanced Security and Durability

Built from high-grade stainless steel (AISI 304 or 316), this concertina wire offers superior resistance to corrosion and tampering. The Standard BTO-22 barbed blade and tightly wound helical loops provide formidable deterrence against unauthorized entry, making it ideal for areas demanding enhanced physical barriers.

Easy Installation and Versatile Packing

Supplied in rolls or coils with waterproof wrapping, installation is straightforward and quick using clamping or tying techniques onto fences or walls. The products design ensures transportation and unpacking are simple, while the robust packaging protects the wire during transit and storage.

FAQs of Concertina Wire:

Q: How is the concertina wire with Standard BTO-22 blades typically installed?

A: The wire is usually installed by clamping or tying the spiral coils onto existing fences, walls, or specially designed structures. This method ensures tight, stable positioning and maximizes security effectiveness.Q: What security applications is this concertina wire best suited for?

A: It is primarily used in high-security environments such as border security, military facilities, industrial perimeters, and any area requiring formidable access control.Q: When should I consider using stainless steel concertina wire over galvanized alternatives?

A: Stainless steel offers higher corrosion resistance and durability, making it especially suitable for coastal regions, humid environments, or locations where the wires long service life (10-20 years) is prioritized.Q: Where is this concertina wire manufactured and exported from?

A: This product is manufactured, supplied, and exported from India by reputable traders, suppliers, and manufacturers specializing in high-security fencing solutions.Q: What are the benefits of the spiral/helical coil type for concertina wire?

A: The spiral or helical design enables the coils to expand efficiently, creating an immediate and intimidating barrier. This structure also increases the wires resilience and adaptability to varied installation settings.Q: How does the wires tensile strength contribute to its performance?

A: With a core wire tensile strength between 1200 and 1600 MPa, the concertina wire is exceptionally difficult to cut or deform, significantly improving its effectiveness as a deterrent and physical obstruction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concertina Wire Category

Steel Concertina Wires

Price Range 650.00 - 1200.00 INR / Piece

Minimum Order Quantity : 10

Application : Other, Perimeter Security, Fencing, Military, Prisons

Wire Gauge : 1014 SWG

Mesh Type : Steel Wire Mesh

Aperture : 45100 mm

Concertina Razor Coil

Application : Other, Perimeter Security, Fencing, Military, Prisons

Wire Gauge : Standard: 12 to 14 SWG

Mesh Type : Steel Wire Mesh

Aperture : Approx. 100 mm spacing between each loop

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry