Fine Wire Mesh

Price 50 INR/ Square Foot

Fine Wire Mesh Specification

- Aperture

- 0.5 mm to 2 mm

- Surface Treatment

- Polished

- Hole Shape

- Square

- Wire Gauge

- Standard Fine Gauge

- Length

- Customizable; typical rolls are 30 meters

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Woven Mesh

- Material

- Steel

- Alloy

- Stainless Steel Grade 304

- Application

- Filtration, sieving, protection, screening, sorting

- Dimensions

- Available widths: 1 meter, 1.2 meters; can be customized

- Wire Diameter

- 0.16 mm to 0.5 mm

- Weight

- Varies by size; approx 0.5 kg/m

- Color

- Silver

Fine Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

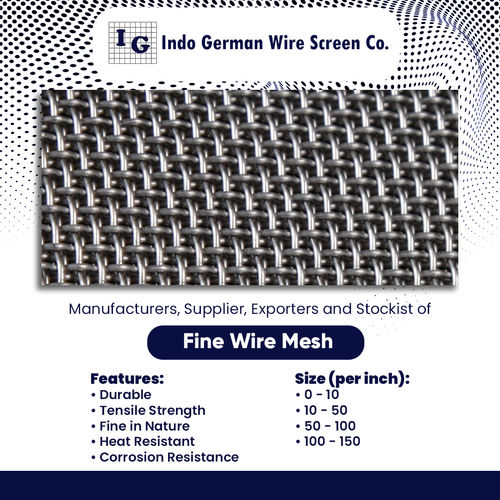

About Fine Wire Mesh

We are considered as one of the reputed companies engaged in manufacturing and supplying Fine Wire Mesh. Also called technical cloth, it is a simple and oblique weave screen. It is highly preferred because of its light structure and design. To deliver the best quality mesh, it goes through various quality tests. This is made using high- grade materials for high durability and strength. It can be used in infrastructure projects, commercial sites, manhole chambers, tunnels, and construction sites. Fine Wire Mesh also serves various security purposes by keeping you secured within the premises you are.

Special Features :

- This 316 or 304 grade stainless steel wire made mesh is acid and alkali proof.

- Used for filtering purpose, available in standard width range

- Homogeneous surface, high strength and good stress enduring performance

- Wear proof surface, excellent strength, wear proof design and high yield strength

Product details

|

Material Grade |

Type 304, Type 304 L, Type 316 and Type 316 L, and Type 304 stainless steel. |

|

Material |

SS / Phosphorous / Bronze / Brass |

|

Weave Type |

Hexagonal,Twill |

|

Standard Roll Width |

1m, 3ft, and 4 ft |

|

Standard Roll Length |

15 m and 30 m |

High Durability and Performance

Engineered with stainless steel grade 304, this fine wire mesh withstands harsh industrial conditions and high temperatures up to 800C. Its remarkable corrosion resistance makes it well-suited for outdoor usage and demanding filtration applications. The polished surface enhances both appearance and product longevity.

Versatile Applications

This steel wire mesh serves diverse purposes including filtration, sieving, protection, screening, and sorting. Its customizable dimensions and variety of aperture and wire diameter options enable it to meet specific industry requirements, from industrial manufacturing to agricultural use.

Customizable Solutions

We offer mesh with customizable lengths and widths, ensuring a perfect fit for any project. Select from cut or selvage edge types for tailored applications, and benefit from various packing options such as rolls, wooden cases, or carton boxes to ensure ease of transport and storage.

FAQs of Fine Wire Mesh:

Q: How is the fine wire mesh typically installed or used in filtration and screening applications?

A: The fine wire mesh is installed by stretching or framing it over filtration or screening units. Its woven structure and customizable dimensions ensure effective separation of particles, making it suitable for filtration, sieving, and screening tasks in industrial, agricultural, and outdoor settings.Q: What are the benefits of choosing stainless steel grade 304 mesh for outdoor and industrial purposes?

A: Stainless steel grade 304 mesh delivers excellent corrosion resistance and temperature endurance up to 800C. These properties ensure longevity even in challenging outdoor and industrial environments, while the polished finish provides added durability and a refined look.Q: When should I select a cut edge versus a selvage edge for my mesh?

A: Cut edge mesh offers flexibility and easier sizing for custom installations, while selvage edge mesh provides reinforced borders for extra durability and reduced fraying. The choice depends on your applications mechanical demands and handling requirements.Q: Where can I customize the meshs size and select specific packing types?

A: Customizations for mesh width, length, aperture, and wire diameter can be requested directly from the manufacturer, exporter, or supplier. Choose packaging optionsrolls, wooden cases, or carton boxesbased on your transportation and storage needs.Q: What is the process for ordering fine wire mesh with specific dimensions or characteristics?

A: To order customized mesh, specify your requirementsincluding width, length, wire diameter, aperture, edge type, and packing preferencewhen contacting the manufacturer or supplier. Orders are produced to your specifications, ensuring precise fit and function.Q: How does the meshs open area range from 35% to 80% benefit its use?

A: A variable open area allows the mesh to be tailored for different filtration and screening needs, providing optimal flow rates and particle retention. This flexibility makes the mesh effective for both coarse and fine filtering tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Different Shape Wire Mesh Category

Square Wire Mesh

Price Range 100.00 - 500.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Material : Aluminum

Product Type : Wire Mesh

Color : Silver

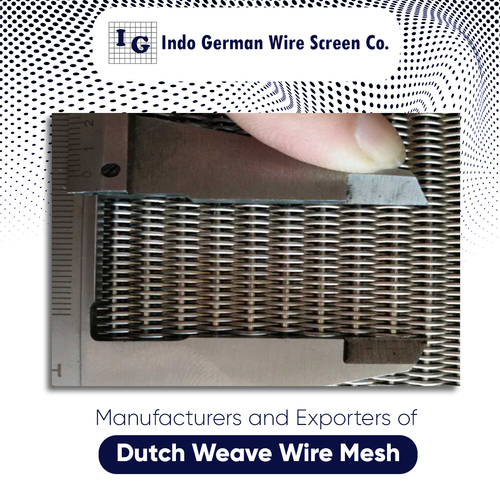

Dutch Weave Wire Mesh

Price 110 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Other, Stainless Steel (SS304, SS316) or Brass

Product Type : Wire Mesh

Color : Silver

Diamond Wire Mesh

Price 16 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Material : Aluminum

Product Type : Wire Mesh

Color : Silver

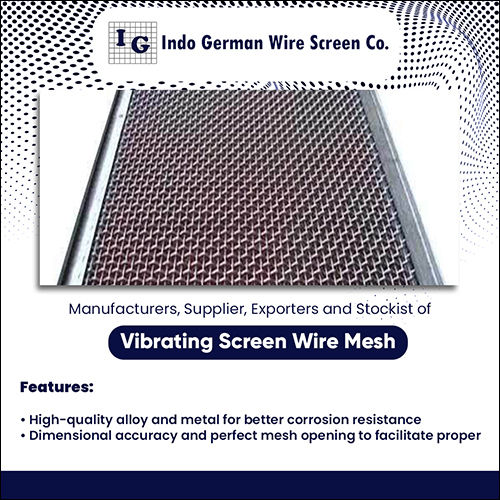

Vibrating Screen Wire Mesh

Price Range 2000.00 - 10000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Aluminum

Product Type : Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry