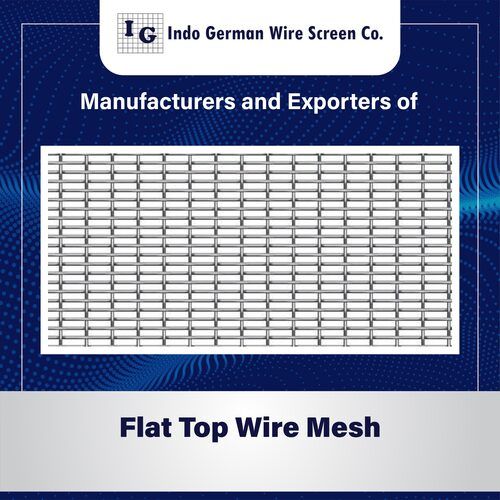

Flat Top Wire Mesh

Flat Top Wire Mesh Specification

- Surface Treatment

- Polished

- Aperture

- 2 mm to 50 mm (as required)

- Length

- as per specification or customised

- Hole Shape

- Rectangular

- Wire Gauge

- as per requirement

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Flat Top

- Material

- Steel

- Alloy

- Non-Alloy or as per order

- Application

- Industrial, Mining, Screening, Fencing, Construction

- Dimensions

- as per customer requirement

- Wire Diameter

- 2 mm to 12 mm (customizable)

- Weight

- Depends on size and specification

- Color

- Sliver

- Corrosion Resistance

- High

- Edge Type

- Cut Edge / Folded Edge

- Finishing

- Smooth Flat Surface

- Tensile Strength

- 350-900 MPa

- Operating Temperature

- up to 550°C

- Open Area Percentage

- 30% - 85% (as per mesh design)

Flat Top Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Supply Ability

- 10 Square Meters Per Day

- Delivery Time

- 1 Week

About Flat Top Wire Mesh

Product Details:

| Mesh Size(per inch) | 0-10 |

| Surface Finish Coating | Black Powder, Mill Finish |

| Weave Type | Hexagonal, PSW |

We are one of the leading manufacturers, supplier, exporters and stockist of Flat Top Wire Mesh in Mumbai, India.

Flat top crimped wire mesh, also called as pressed crimped wire mesh is made from round and profiled plain weave wire. All the mesh knuckles is being on the underside. The structure of Flat Top Crimped Wire Mesh is very heavy and durable. The smooth surface is the characteristic of the weaving method. This structure can allow the materials to move more freely over the screen. It is widely used in the vibrating screen.

Customizable Edge and Mesh Options

Choose between cut or folded edge types to best suit your installation requirements. The mesh can be customized in terms of wire gauge, length, aperture, wire diameter, and overall dimensions, ensuring a precise fit for your industrial, mining, screening, or construction project needs.

Enhanced Durability and High Performance

Featuring smooth, polished surfaces and superior tensile strength ranging from 350 to 900 MPa, this steel wire mesh provides exceptional durability and high corrosion resistance. Its robust construction allows operation at temperatures up to 550C, making it well-suited for harsh or demanding environments.

FAQs of Flat Top Wire Mesh:

Q: How is the Flat Top Wire Mesh installed for industrial applications?

A: Flat Top Wire Mesh can be installed using suitable fixing methods corresponding to the edge type chosen, such as welding, bolting, or clamping systems. The choice between cut or folded edge ensures secure and efficient installation for varied environments like screening or fencing.Q: What customization options are available for this wire mesh product?

A: Customization includes dimensions, wire gauge, aperture size (2 mm to 50 mm), wire diameter (2 mm to 12 mm), and mesh style. You can select the open area percentage and edge type as per specific project requirements, ensuring optimal performance and fit.Q: When should the polished Flat Top Wire Mesh be used?

A: The polished Flat Top Wire Mesh is recommended when both corrosion resistance and a smooth surface finish are required, such as in industries where hygiene, durability, and minimal particle adherence are essential. Its operating temperature tolerance also makes it suitable for high-temperature environments.Q: Where can the Flat Top Wire Mesh be applied effectively?

A: This mesh excels in industrial, mining, screening, fencing, and construction sectors. Its customizable nature allows it to be deployed wherever robust, corrosion-resistant separation, filtration, or protection is needed.Q: What benefits do the different edge types provide?

A: A cut edge provides a simple finish ideal for quick installation and cost efficiency, while a folded edge enhances strength and safety by reducing sharpness, making handling and installation safer in more demanding applications.Q: How does high tensile strength contribute to mesh performance?

A: A tensile strength range of 350-900 MPa ensures the mesh can withstand heavy loads, pressure, and impact, making it resilient against mechanical stress and deformation. This is particularly beneficial in industrial and screening applications.Q: What is the process for ordering custom specifications for the Flat Top Wire Mesh?

A: To order custom specifications, provide details on desired wire gauge, aperture size, wire diameter, dimensions, edge type, and application requirements. The manufacturer or supplier will tailor the mesh design to match your exact needs, ensuring optimal functionality and value.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Wire Cloth

Price Range 40.00 - 400.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Surface Treatment : Polished

Material : Steel

Mesh Type : Steel Wire Mesh

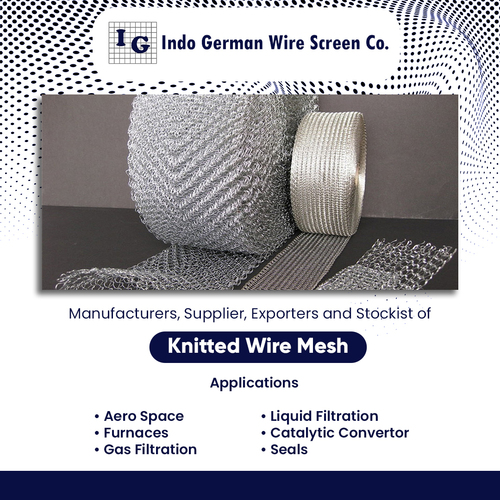

Knitted Wire Mesh

Price Range 325.00 - 450.00 INR / Kilograms

Minimum Order Quantity : 10 Kilograms

Surface Treatment : Polished

Material : Steel

Mesh Type : Other , knitted wire net

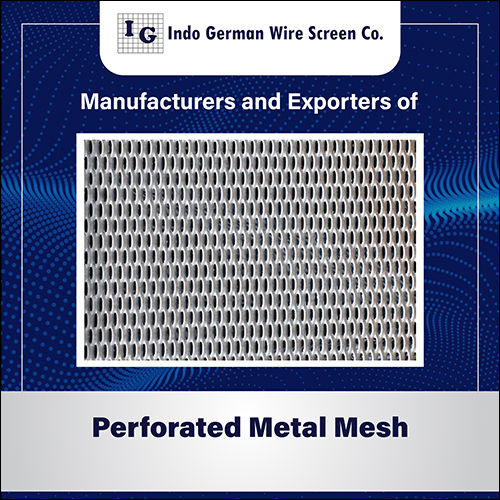

Perforated Metal Mesh

Price Range 75.00 - 500.00 INR / Square Foot

Minimum Order Quantity : 32 Square Foots

Surface Treatment : Plated

Material : Steel

Mesh Type : Steel Wire Mesh

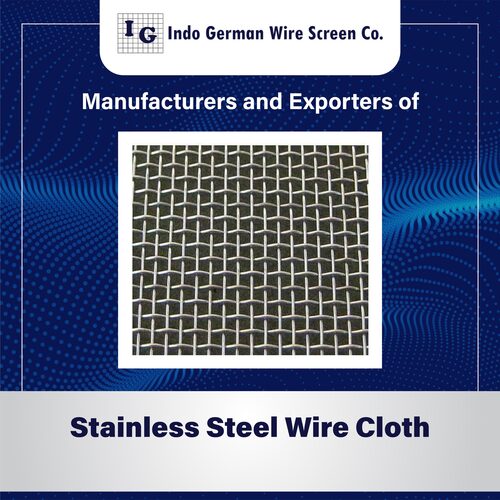

Stainless Steel Wire Cloth

Price Range 50.00 - 500.00 INR / Square Foot

Minimum Order Quantity : 50 Square Foots

Surface Treatment : Polished

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry