Inconel Wire Mesh

Inconel Wire Mesh Specification

- Wire Gauge

- 10-100 SWG

- Aperture

- 0.5 mm to 10 mm

- Length

- 15-30 Meter (m)

- Surface Treatment

- Polished

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Woven Mesh

- Material

- Steel

- Alloy

- Inconel 600/625/718

- Application

- Food Industry

- Dimensions

- As per requirement

- Wire Diameter

- 0.5 mm to 2 mm

- Weight

- As per specification

- Color

- Sliver

Inconel Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton box

- Main Domestic Market

- All India

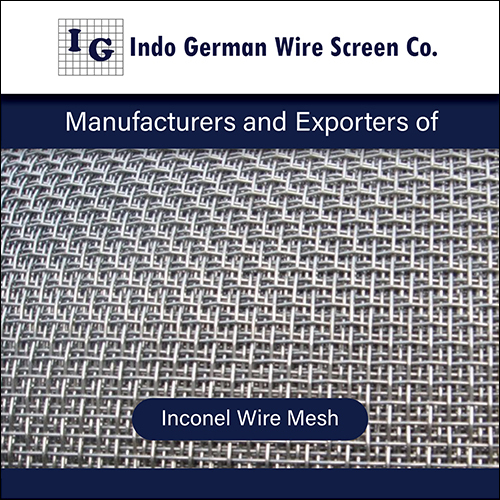

About Inconel Wire Mesh

We are a unique entity in the market, actively committed towards providing an optimum range of Inconel Wire Mesh. Inconel is a mixture of nickel-chromium alloy and aluminium. Resistant to corrosive environment, flawless finish, effective at high temperature, high tensile strength and long life are qualities of offered wire mesh. Due to its superior quality, our provided wire mesh is widely demanded among clients. In addition to this, our quality experts check this Inconel Wire Mesh on various parameters to avoid any flaws.

Types of Inconel wire mesh

Inconel 600 wire mesh

- Composition Ni 72% min, Cr 14.0-17.0%, Fe 6.0-10.0%

- Specifications ASTM B166, AMS 5687

Inconel 601 wire mesh

- Composition Ni 58.0-63.0%, Cr 21.0-25.0%, Al 1.0-1.7%, Fe rem

- ]Specifications ASTM B166, AMS 5715

Inconel 617 wire mesh

- Composition Ni 44.5% min, Cr 20.0-24.0%, Co 10-15%, Mo 8-10%, Fe 3% max

- Specifications ASTM B166

Inconel 625 wire mesh

- Composition Ni 61%, Cr 21.5%, Mo 9%, Nb+Ta 3.6%

- Specifications ASTM B446, AMS 5837

Inconel 718 wire mesh

- Composition Ni 52.5%, Cr 19%, Fe 18.5%, Mo 3.0%, Nb+Ta 3.6%

- Specifications ASTM B637

Exceptional Durability and Resistance

Inconel Wire Mesh stands out due to its exceptional resistance to heat, up to 1100C, and corrosion, rendering it suitable for demanding environments. Crafted using plain or twill weave methods, it maintains a high tensile strength regardless of its customized specifications. The meshs polished surface ensures both longevity and a high standard of hygiene, vital for food processing industries.

Customizable for Multiple Industrial Uses

Designed to be versatile, Inconel Wire Mesh is available in a variety of dimensions, wire diameters, and opening sizes as per specific requirements. Its flexibility in formprovided as rolls or cut piecesmeans it can seamlessly integrate into various processes. The mesh is widely used in the food industry, but its robust properties also make it valuable across chemical, filtration, and thermal applications.

FAQs of Inconel Wire Mesh:

Q: How is Inconel Wire Mesh manufactured to meet different industrial standards?

A: Inconel Wire Mesh is crafted using advanced weaving technologies, producing both plain and twill patterns. It is manufactured to adhere strictly to ASTM, DIN, and ISO standards, ensuring consistent quality for a wide range of applications.Q: What benefits does Inconel Wire Mesh offer for the food industry?

A: The meshs excellent corrosion resistance, high-temperature tolerance (up to 1100C), and polished surface prevent contamination and ensure hygienic processing. Its customizability makes it ideal for various food industry processes, from filtering to sieving.Q: When should I choose plain or twill weave for my application?

A: Plain weave provides uniform opening sizes and is suitable for general filtration. Twill weave offers added strength and flexibility, recommended for applications requiring higher durability or where heavier loads are involved.Q: Where can Inconel Wire Mesh be used aside from the food industry?

A: Due to its strength and resistance to extreme conditions, Inconel Wire Mesh is valuable in chemical processing, heat exchangers, filtration systems, and aerospace applications requiring dependable performance under stress.Q: What is the process for customizing mesh dimensions and opening sizes?

A: Customers can specify requirements such as aperture size (0.5 mm to 10 mm), wire gauge (10-100 SWG), mesh style, and dimensions. The mesh is then woven and fabricated accordingly, ensuring a perfect match for the intended application.Q: How is the mesh packed and delivered to maintain quality?

A: After fabrication, the mesh is securely packed in wooden cases or as per the clients requirements, protecting it from damage during transit. This ensures it arrives in pristine condition, ready for installation or further processing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

410 Stainless Steel Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Mesh Type : Other , Fine Mesh

Application : Other

Inconel 600 Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Inconel 600

Mesh Type : Other , Crimped / Plain

Application : Other, High temperature filtration, Chemical processing, Aerospace, Power generation

Wire Mesh in SS/MS/Spring Steel/Brass

Price Range 25.00 - 250.00 INR

Minimum Order Quantity : 100 Square Foots

Material : Steel

Mesh Type : Steel Wire Mesh

Application : Decoration, Food Industry

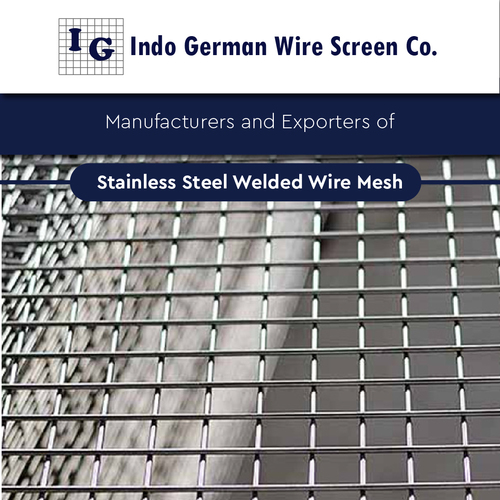

Stainless Steel Welded Wire Mesh

Price Range 50.00 - 170.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Material : Steel

Mesh Type : Steel Wire Mesh

Application : Decoration, Food Industry

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry