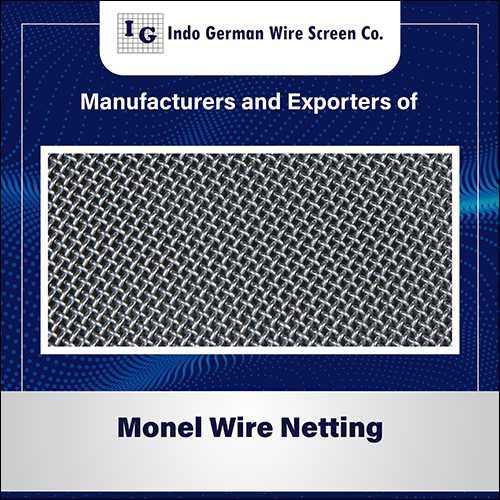

Monel Wire Netting

Monel Wire Netting Specification

- Usage

- industrial

- Material

- Monel

- Type

- Wire Netting

- Hole Shape

- Square

- Product Type

- Monel Wire Netting

- Hole Size

- 1 mm to 25 mm

- Weave Style

- Plain Weave

- Application

- Industrial, Chemical Processing, Filtration, Marine Applications

Monel Wire Netting Trade Information

- Supply Ability

- 10 Per Day

- Delivery Time

- 1 Week

About Monel Wire Netting

The provided Monel Wire Netting is demanded in agricultural field, farm house, constructional sites and several other industries. Banking on our advance production unit, this wire-mesh is made with high precision with the utilization of fine grade raw materials and latest technology under the supervision of our adroit experts to meet the set market standards. Apart from this, offered Monel Wire Nettingis available in diverse specifications at rock-bottom prices.

Product details

|

Usage |

Industrial |

|

Material |

Monel |

|

Roll Size |

1mt / 4 ft width x 30 mtr length |

|

Condition |

New |

|

I Deal In |

New Only |

|

Material Grade |

Monel 400,Monel 500 |

Superior Corrosion and Temperature Resistance

Monel Wire Netting boasts exceptional resistance to both corrosion and high temperatures, enduring up to 800C. Its unique composition enables the netting to thrive in acidic and alkaline environments, making it a trusted choice for chemical processing, marine, and industrial filtration tasks. The products durability ensures reliable performance in highly aggressive settings.

Customizable Solutions for Diverse Applications

Our wire netting is available in various wire diameters and mesh sizes, with square holes ranging from 1 mm to 25 mm. Clients can customize thickness and length to suit specific project requirements. Whether used for filtration, marine applications, or chemical processing, this product adapts seamlessly to your needs, ensuring operational excellence across industries.

FAQs of Monel Wire Netting:

Q: How is Monel Wire Netting used in industrial filtration and chemical processing?

A: Monel Wire Netting acts as a barrier to separate particles and contaminants during filtration and acts as protective screens or trays in chemical processing. Its square hole design and customizable dimensions make it efficient for precise separation and filtration tasks in demanding environments.Q: What benefits does the annealed or uncoated surface treatment offer?

A: The annealed finish ensures the netting remains flexible and easy to shape during installation, while the uncoated option provides a pure metallic surface, ideal for processes requiring minimal contamination or reactive interference.Q: When should Monel Wire Netting be chosen over other wire netting materials?

A: It is best selected when applications demand high corrosion resistanceespecially in acidic or alkaline conditionsand superior temperature endurance up to 800C, outperforming most alternative alloys in these scenarios.Q: Where is Monel Wire Netting typically installed?

A: Widely adopted in filtration units, chemical processing plants, and marine equipment, Monel Wire Netting serves as protective screens, partitions, and filtering elements where mechanical strength and corrosion resistance are essential.Q: What is the manufacturing process for Monel Wire Netting?

A: Monel Wire Netting is produced through precision weaving of Monel wires into a plain weave pattern, forming square holes. Each batch can be tailored for wire diameter, mesh size, thickness, and length according to client specifications.Q: What customization options are available for this wire netting?

A: Buyers can specify thickness, length, wire diameter (0.5 mm to 2 mm), mesh size (10 to 100 mesh), and hole dimensions (1 mm to 25 mm), ensuring the netting perfectly fits their operational requirements.Q: How does the excellent temperature resistance benefit marine and industrial applications?

A: Its ability to withstand up to 800C enables reliable use in high-temperature processes, such as chemical reactions and marine engine filtration, where long-term durability and consistent performance are critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Safety Net Category

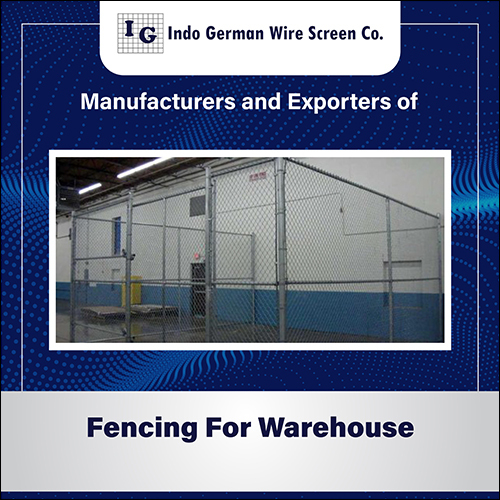

Fencing For Warehouse

Price 1000 INR / Foot

Minimum Order Quantity : 10 Feet

Product Type : Fencing For Warehouse

Material : Other, Mild Steel

Type : Other, Fencing For Warehouse

Color : Sliver

Wire Net

Price 1000 INR / Foot

Minimum Order Quantity : 10 Feet, ,

Product Type : Heat resistance

Material : Other, SS

Type : Other, Wire Net

Color : Steel

Construction Safety Nets

Price 80 INR / Square Foot

Minimum Order Quantity : 200 Square Foots

Product Type : Construction Safety Nets

Material : Metal

Color : Green

Scramble Nets

Price 6.00 INR / Square Foot

Minimum Order Quantity : 200 Square Foots

Product Type : Scramble Nets

Material : Other, SS

Type : Netting

Color : Sliver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry