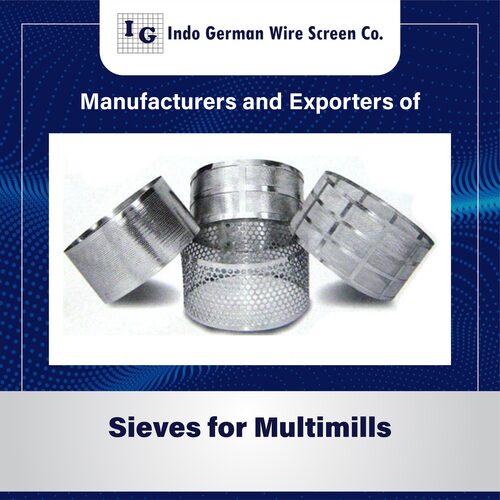

Multi Mill Sieves

Multi Mill Sieves Specification

- Product Type

- Multi Mill Sieves

- Material

- Metal

- Size

- 50 microns to 20 mm

- Color

- Silver

Multi Mill Sieves Trade Information

- Minimum Order Quantity

- 5 Pieces

- FOB Port

- mumbai

- Payment Terms

- Paypal, Letter of Credit (L/C), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Multi Mill Sieves

Milling depends on many factors like physical & chemical characteristics of the product, design of the machine, the design of hammers, environmental conditions & most importantly, the type of sieves used. Sieve parameters like the size & shape of the aperture, pitch & thickness play a very important role in material processing.

Product details

|

Hole Shape |

Circular, Square |

|

Hole Size |

50 microns to 20 mm |

|

Material |

Stainless Steel-316 and 316-L Quality |

|

Material Grade |

ASTM E-674, ASTM E-454 |

|

Type |

Woven |

Versatile Mesh Sizes for Precision

Our multi mill sieves accommodate a vast range of particle separation requirements, offering mesh sizes from as fine as 50 microns up to 20 mm. This flexibility ensures precise results, whether youre working with powders or larger granules, making our sieves suitable for diverse applications in pharmaceuticals, chemicals, food processing, and more.

Durable Construction with Quality Materials

Manufactured using high-grade metal and aluminum, our sieves feature a plated finish that enhances resistance to wear, corrosion, and frequent handling. The superior build quality ensures longevity and consistent performance even under rigorous industrial conditions, guaranteeing a sound investment for your filtration needs.

FAQs of Multi Mill Sieves:

Q: How are the Multi Mill Sieves manufactured and what surface treatment do they have?

A: Our Multi Mill Sieves are manufactured using high-quality metal and aluminum, and are finished with a plated surface treatment. This enhances their corrosion resistance and ensures long-term durability even in challenging industrial environments.Q: What is the typical process for using these sieves in industrial applications?

A: The sieves are integrated into multi mill or filtration machinery. Materials are fed through the aluminum wire mesh, where precise particle separation occurs based on the selected mesh sizefrom 50 microns to 20 mmfacilitating efficient processing and quality control.Q: Where can these Multi Mill Sieves be used, and which industries do they serve?

A: Our sieves are widely utilized across various sectors including pharmaceuticals, food processing, chemicals, and other manufacturing industries. They are ideal for applications that require controlled particle sizing, screening, and filtration.Q: When should a customer consider replacing or upgrading their sieves?

A: Sieves should be replaced if there are visible signs of damage, wear, or a drop in filtration efficiency. Regular inspections and timely replacements help maintain optimal performance and prevent contamination or compromised product quality.Q: What are the usage benefits of choosing aluminum wire mesh sieves in silver and black finishes?

A: The aluminum wire mesh provides lightweight strength, excellent corrosion resistance, and long service life. The silver and black plated finishes not only enhance aesthetics but also add an extra protective layer, making these sieves suitable for demanding environments.Q: How do the different mesh sizes benefit industrial users?

A: The availability of a wide mesh size range allows users to select the precise level of filtration or particle separation needed for their process, improving efficiency, consistency, and end product quality across diverse applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sifter Sieves Category

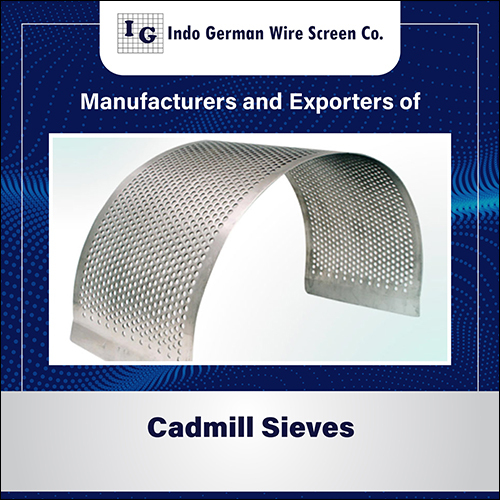

Cadmill Sieves

Price Range 1200.00 - 5000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Color : Black

Product Type : Cadmill Sieves

Material : Others, Stainless Steel

Size : 52 Mm x 542 Mm

Test Sieves

Price Range 1750.00 - 5500.00 INR / Piece

Minimum Order Quantity : 2 Pieces

Color : Sliver

Product Type : Test Sieves

Material : Others, Copper

Size : 20 40 inch

Lead Free Turbo Sifter Sieves

Price Range 2000.00 - 15000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Color : Sliver

Product Type : Lead Free Turbo Sifter Sieves

Material : Others, Stainless Steel

Size : 20, 30, 40, 48 inch

Pharma Sifter Sieves

Price Range 1550.00 - 10000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : Silver

Product Type : Pharma Sifter Sieves

Material : Stainless Steel

Size : 20 40 inch

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry