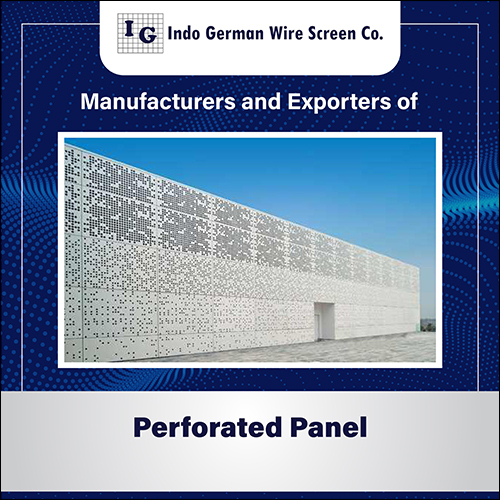

Perforated Panel

Price 85 INR/ Square Foot

Perforated Panel Specification

- Shape

- Circular

- Usage

- industrial

- Material

- Stainless Steel Wire

- Technique

- Perforated

- Product Type

- Perforated Panel

- Application

- For Industrial

Perforated Panel Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Perforated Panel

We are considered as one of the reputed companies engaged in manufacturing, exporting and supplying Perforated Panel. Excellent quality raw materials and latest technologies are used in the manufacturing process. Due to its sturdiness and anti-abrasive feature, it is appreciated globally. It is manufactured under the supervision of our experts and in accordance with the industry laid laws. They are resistant to corrosion, versatile and have a sturdy structure. Perforated Panel is used in various ways as shields, filters, screens, and guards. Due to their aesthetics, they are used in architectural and design applications such as fixtures, facades, and privacy panels.

Special Features ofPerforated Panel:

- Aluminum or stainless steel made panel is used for decoration and safety purpose.

- Featured with plain weave pattern and available in custom made specifications

- High tensile strength, wear proof, skid protected, simple installation method and affordable price

- Highly durable and high strength, low maintenance cost and prolonged working life

Product Details

|

Length |

1-6m |

|

Usage |

Industrial |

|

Width |

0.5m-2m |

|

Weave Style |

perforated |

|

Technique |

Perforated |

Engineered for Industrial Demands

These panels are manufactured using high-grade stainless steel wire, offering robust resistance to corrosion and wear. Their circular shape and precise perforation patterns maximize airflow while maintaining structural integrity, making them suitable for a variety of heavy-duty industrial purposes.

Customizable and Globally Supplied

Recognized as a reputable exporter and supplier in India, we provide tailored solutions to fit unique specifications. Whether for machinery guards, filtration, or screening, our manufacturing process ensures panels that suit both local and international industrial standards.

FAQs of Perforated Panel:

Q: How are circular perforated panels made from stainless steel wire?

A: Circular perforated panels are manufactured using advanced perforation techniques where stainless steel wire is shaped and punched to create uniform holes. This process ensures consistent quality, precision, and durability suitable for various industrial applications.Q: What are the primary industrial applications of these perforated panels?

A: These panels are commonly used in industries for filtration, screening, machine guarding, and sound isolation. Their robust construction makes them ideal for environments where strength and ventilation are crucial.Q: When should I choose a stainless steel perforated panel over other materials?

A: Stainless steel is preferred for its superior resistance to corrosion, high temperatures, and demanding industrial conditions. If your application requires longevity and minimal maintenance, stainless steel perforated panels are the ideal choice.Q: Where can these perforated panels be installed in industrial settings?

A: Circular perforated panels can be installed in manufacturing plants, processing units, and machinery enclosures, wherever controlled airflow, protection, and filtration are required.Q: What is the typical process for ordering these panels from your company?

A: Customers can reach out with their specifications such as size, perforation pattern, and application. We then manufacture the panels according to those needs and ship worldwide, ensuring timely delivery and full support during the selection process.Q: How are these panels beneficial for industrial applications?

A: Their benefits include enhanced durability, corrosion resistance, and adaptability. The perforated design improves ventilation and filtration, helping to protect equipment while optimizing operational efficiency.Q: What advantages do you offer as an exporter and manufacturer in India?

A: We provide competitive pricing, prompt exports, and the ability to customize products for diverse applications. Our commitment to quality and reliability has established us as a trusted partner for industrial clients globally.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

Sifter Sieves For Granules

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Product Type : Sifter Sieves

Material : Stainless Steel

Usage : industrial

Technique : Other, Perforated/ Woven Mesh fabrication

Sieve for Conical Mills

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Product Type : Sieve for Conical Mills

Material : Stainless Steel

Usage : industrial

Technique : Other, Perforated and wire mesh

Sifter Sieves For Pharma Industry

Price 1000 INR / Foot

Minimum Order Quantity : 10 Feet, ,

Product Type : Sifter Sieves For Pharma Industry

Material : Stainless Steel

Usage : industrial

Technique : Other, Perforated and woven mesh technology

Perforated Coils

Minimum Order Quantity : 10 Square Foots

Product Type : Perforated Coils

Material : Stainless Steel Wire

Usage : industrial

Technique : Perforated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry