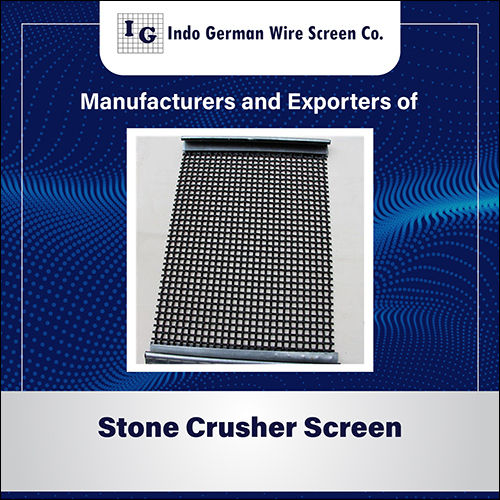

Stone Crusher Screen

Stone Crusher Screen Specification

- Surface Treatment

- Polished

- Product Type

- Wire Mesh

- Mesh Type

- Aluminum Wire Mesh

- Mesh Style

- Chain Link Mesh

- Material

- Aluminum

- Application

- Screen

- Color

- Silver

Stone Crusher Screen Trade Information

- Minimum Order Quantity

- 100 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Stone Crusher Screen

Stone Crusher Screen is extensively utilized in construction industry for separating uniform sizes of stones from crushing machine. Made of high grade steel alloy, it is said to have the excellent abrasion & wear resistance with long service life and high durability. This screen is structurally strong and has been fabricated using hot rolled method. It is provided with lustrous surface and superior resistance to deformation. Stone Crusher Screen offered by us is highly demanded in market for having flat top and assuring excellent working efficiency. It can be availed in different mesh sizes at reasonable prices for our clients.

We are one of the renowned and reliable manufacturers, supplier, stockist and exporter of Stone Crusher screen in Mumbai, India.

Special Features :

- Round or looped woven wire made screen is used as integral part of dewatering system.

- Made of alloy steel or stainless steel

- Excellent strength, prolonged working life, accurate diameter and rust proof

- Durable structure and oxidation protected

Product details

|

Material Grade |

SS 304, 316 |

|

Usage |

Industrial |

|

Capacity |

1 mm wire dia to 16 mm wire dia |

|

Corrosion Resistant |

Yes |

|

Material |

SS, MS, Alloy steel,MS,Alloy steel |

|

Type |

Screen |

Premium Aluminum Wire Mesh for Stone Crusher Screens

These screens utilize superior aluminum wire mesh, which is lightweight yet durable. The chain link mesh style ensures effective screening and separation of materials in crushing operations. The polished surface finish not only enhances resilience against environmental factors but also keeps maintenance straightforward. Supported by our expertise as an exporter and manufacturer in India, we deliver reliable solutions for the stone crushing sector.

Enhanced Performance and Longevity

The aluminum construction coupled with a polished surface treatment makes our screens corrosion-resistant and capable of withstanding demanding industrial environments. The chain link mesh design ensures optimal filtration and minimal material blockage, leading to increased productivity. Our commitment as a supplier and trader is to provide products that combine efficiency, strength, and long-lasting performance.

FAQs of Stone Crusher Screen:

Q: How is the aluminum chain link mesh screen used in stone crushing applications?

A: The aluminum chain link mesh screen is installed in stone crushers to separate and filter different sizes of crushed stones. Its robust mesh structure allows efficient passage of smaller particles while retaining larger stones, facilitating effective material separation.Q: What are the advantages of choosing an aluminum wire mesh screen for stone crushers?

A: Aluminum wire mesh screens offer corrosion resistance, lightweight strength, and flexibility. The polished surface treatment further protects against environmental wear, making them ideal for high-performance screening in stone crushing environments.Q: When should the stone crusher screen be replaced or maintained?

A: Screen maintenance should be carried out periodically, depending on the frequency of usage and type of material processed. Replacement is recommended when visible signs of damage, excessive blockage, or reduced screening efficiency are observed.Q: Where can I get these stone crusher screens in India?

A: As leading exporters, manufacturers, suppliers, and traders in India, our stone crusher screens are available through direct order. You can contact us for single units or bulk requirements as per your project needs.Q: What is the process involved in manufacturing the polished aluminum wire mesh screens?

A: The manufacturing process involves weaving aluminum wires into a chain link mesh style, followed by precision cutting and polishing of the surface. This ensures uniform mesh openings, smooth edges, and enhanced durability for industrial applications.Q: How does the polished surface treatment benefit the screens?

A: Polishing provides a smooth finish and improves resistance to corrosion, thereby prolonging the lifespan of the screen. It also reduces the likelihood of material buildup, making maintenance easier and ensuring consistent performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

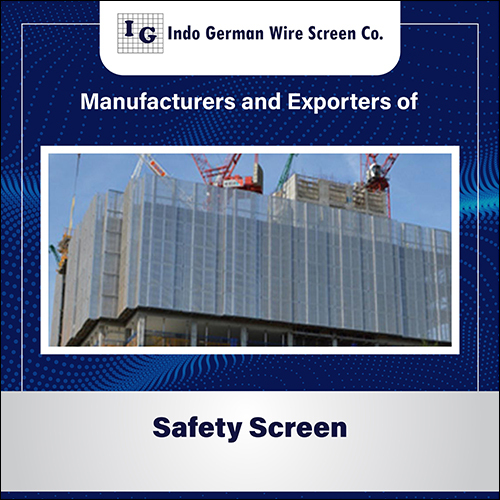

More Products in Safety Screen Category

Safety Screen

Price 50 INR

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Surface Treatment : Polished

Mesh Type : Aluminum Wire Mesh

Application : Screen

Filter Screen

Price 50 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Surface Treatment : Polished

Mesh Type : Aluminum Wire Mesh

Application : Screen

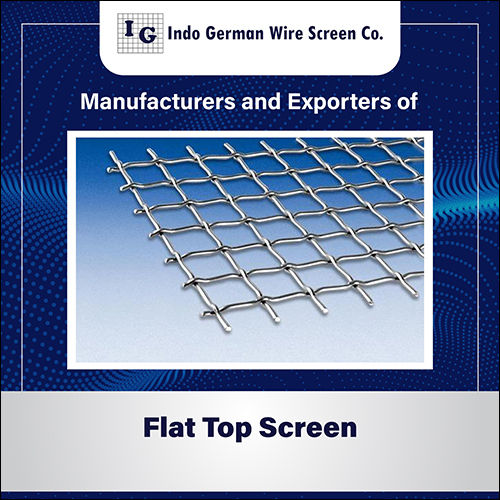

Flat Top Screen

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Surface Treatment : Polished

Mesh Type : Aluminum Wire Mesh

Application : Screen

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry