Wire Mesh Filter

Wire Mesh Filter Specification

- Product Type

- Wire Mesh Filter

- General Use

- Industrial

- Material

- Stainless Steel

- Type

- Wire Mesh

- Automatic

- No

Wire Mesh Filter Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Wire Mesh Filter

We are based in Mumbai and have a great reputation in manufacturing and supplying Wire Mesh Filter. Materials which arent small enough to go through the tiny gaps are caught in the mesh. Expanded metal machining is one of the popular methods for manufacturing such mesh filters. It is preferred more as it avoids the creation of any metal waste during manufacturing. They are prepared using high-grade materials and the latest technologies under the supervision of our experts. Wire Mesh Filter is extensively used in plumbing systems, dryers, automotive oil filters and in other industrial applications.

Special Features :

- Square or diamond shaped mesh, ideal for filtering purpose

- Sintered and spot welded surface pattern, accessibility in custom made specifications

- Made of stainless steel or Monel, corrosion protected and high temperature proof

- Prolonged working life, excellent hardness level and accurate diameter

Product Details

|

Application |

Woven Wire Mesh |

|

Mesh Size |

50-100 per inch,150-200 per inch,10-50 per inch,100-150 per inch,0-10 per inch |

|

Surface Finish Coating |

Black Polyester Coating,Black Powder Coating,Mill Finish Coating |

|

Weave Type |

Hexagonal,Twill,PSW |

|

Usage |

Industrial |

|

Material |

Stainless Steel |

|

Weave Style |

Plain Weave |

Premium Material and Construction

Constructed from stainless steel and high-quality aluminum, our wire mesh filters offer unmatched durability and corrosion resistance. The polished surface not only enhances aesthetic appeal but also simplifies cleaning and maintenance, making these filters particularly advantageous for harsh industrial environments where longevity is essential.

Industrial Versatility

Ideal for a variety of industrial uses, these wire mesh filters support processes such as screening, separation, and filtration of solids from liquids or gases. The plain mesh style ensures uniform strength and high flow rates, making them suitable for applications in chemical processing, food production, and more.

FAQs of Wire Mesh Filter:

Q: How is the wire mesh filter installed in industrial processes?

A: Wire mesh filters are typically fitted into filtration systems or screening units by securing the mesh panels or rolls into frames or housings, ensuring they are taut and free from sagging. Installation depends on the specific industrial application and can vary from bolting to clamping, according to the existing system infrastructure.Q: What are the main advantages of using stainless steel and aluminum in these filters?

A: Stainless steel and aluminum make the filters highly corrosion-resistant, robust, and easy to clean. These materials extend filter life, reduce maintenance, and ensure high performance even in aggressive or moist industrial environments.Q: When should a wire mesh filter be replaced or maintained?

A: The filter should be inspected periodically and cleaned as needed, depending on usage intensity and the type of material being filtered. Replace the mesh if it shows signs of excessive clogging, physical damage, or reduced filtration efficiency to maintain optimum operation.Q: Where can these wire mesh filters be used most effectively?

A: These filters are best suited for applications in industries such as chemical processing, food and beverage, pharmaceuticals, oil and gas, and water treatment, wherever sturdy and reliable filtration is necessary.Q: What is the manufacturing process for plain mesh aluminum wire filters?

A: The process involves weaving individual aluminum wires in a plain mesh pattern on specialized looms, followed by surface polishing to ensure smoothness and shine. The finished mesh is then cut to size and shaped for specific industrial applications.Q: How does the plain mesh style benefit industrial usage?

A: Plain mesh offers consistent openings, robust structure, and effective filtering capacity. Its uniformity allows for higher flow rates, making it suitable for applications requiring quick filtration without loss of structural integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Filter Category

Filter Pads

Price 150 INR

Minimum Order Quantity : 1 , , Piece

Product Type : Filter Pads

General Use : Industrial

Material : Stainless Steel

Automatic : No

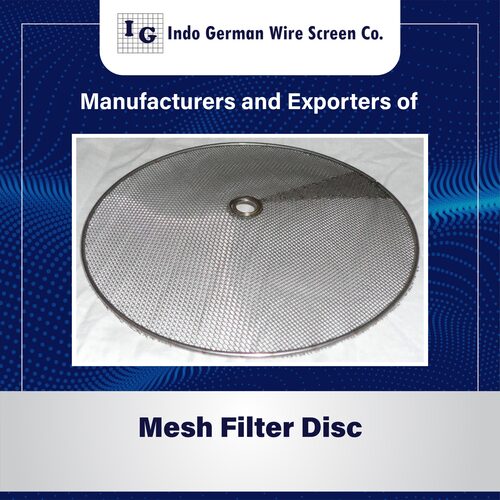

Wire Mesh Filter Discs

Price 2500 INR

Minimum Order Quantity : 1 , , Piece

Product Type : Wire Mesh Filter Discs

General Use : Industrial

Material : Other, Metal Fiber

Automatic : No

Metal Mesh Filter

Minimum Order Quantity : 10 Pieces

Product Type : Metal Mesh Filter

General Use : Industrial

Material : Other, Hastelloy

Automatic : No

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry