310 Stainless Steel Welded Wire Mesh

Price 50 INR/ Unit

310 Stainless Steel Welded Wire Mesh Specification

- Wire Gauge

- SS 310 (as per standard or as required)

- Length

- As required or standard (typically in rolls of 30 m or as custom-cut)

- Surface Treatment

- Coated

- Aperture

- 1/2 to 6 Inch (customizable)

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Welded

- Mesh Style

- Welded Mesh

- Material

- Stainless Steel

- Alloy

- AISI 310

- Application

- Other

- Dimensions

- Custom or Standard (e.g., 1 m x 25 m rolls, 4 ft x 8 ft panels)

- Wire Diameter

- 0.5 mm to 2.5 mm (customizable)

- Weight

- Depends on mesh size and wire diameter (customized per order)

- Color

- Gray

310 Stainless Steel Welded Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About 310 Stainless Steel Welded Wire Mesh

We offer an exclusive range of 310 Stainless Steel Welded Wire Mesh at unmatched quality and market leading prices.310 Stainless Steel Welded Wire Mesh finds applications in sugar graders, for shifting and grading of chemicals, used for cement industries, powders, minerals, and pigments, used for stone crushing industries.These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards.Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.Indo German Wire Screen Co. manufacturing and exporting high quality 310 Stainless Steel Welded Wire Mesh worldwide.

High-Temperature Corrosion Resistance

Designed for harsh environments, 310 Stainless Steel Welded Wire Mesh maintains its integrity at temperatures up to 1150C. Its chromium-nickel composition ensures lasting strength and excellent oxidation resistance, making it suitable for furnaces, heat treatment, and fire protection systems.

Flexible Customization Options

Customers can personalize their mesh with variable wire diameters, mesh apertures, lengths, and panel sizes. Both edges (cut or folded) and various fitting accessories are provided upon request, ensuring compatibility with unique project requirements.

Superior Weldability and Fabrication

The meshs material properties allow for excellent weldability, making it straightforward to cut, shape, or assemble during installation. The coated finish further enhances durability and lifespan for both indoor and outdoor applications.

FAQs of 310 Stainless Steel Welded Wire Mesh:

Q: How is 310 Stainless Steel Welded Wire Mesh typically used in high-temperature environments?

A: This mesh is favored in kilns, furnace linings, heat treatment baskets, and fire protection systems because it retains strength and resists corrosion at continuous operating temperatures up to 1150C.Q: What customization options are available for aperture size, wire diameter, and dimensions?

A: Apertures can be customized from 1/2 inch to 6 inches, wire diameters range from 0.5 mm to 2.5 mm, and dimensions are available as standard rolls or panels, as well as custom-cut lengths and shapes to suit project needs.Q: When should 310 stainless steel mesh be selected over other mesh materials?

A: Choose 310 stainless steel mesh when your application demands excellent corrosion resistance, high temperature stability, and superior mechanical strength, especially in industrial, marine, or thermal processing settings.Q: Where can this welded wire mesh be supplied or exported from?

A: We are leading manufacturers, exporters, suppliers, and traders based in India, and can ship globally according to customer requirements.Q: What is the process for fabricating or welding 310 stainless steel mesh?

A: 310 stainless steel boasts excellent weldability. Standard fabrication techniques can be used, ensuring that structures requiring high temperature service are strong and resistant to stress cracking.Q: How does the coated surface treatment benefit the mesh?

A: The coated finish increases resistance to chemicals, moisture, and environmental wear, extending the meshs service life in both indoor and outdoor settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

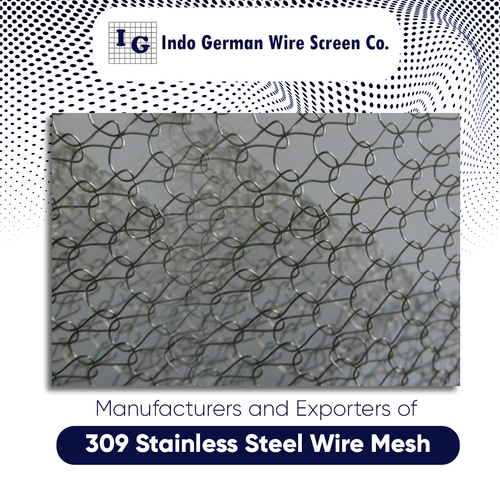

309 stainless steel wire mesh

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Mesh Style : Woven Mesh

Product Type : Wire Mesh

Hole Shape : Square Hole

Color : Silver

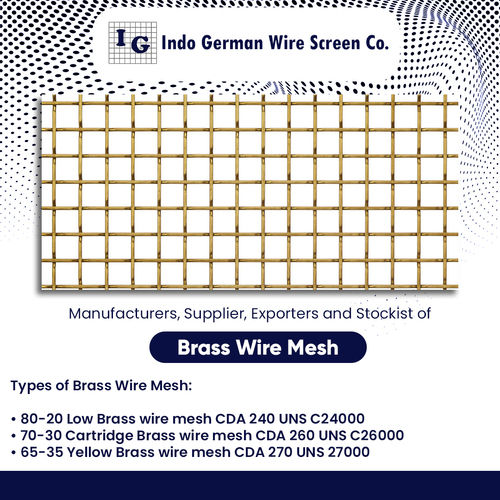

Bronze Wire Mesh

Price 100 INR / Square Foot

Minimum Order Quantity : 10 Units, ,

Mesh Style : Other , Plain Weave

Product Type : Wire Mesh

Hole Shape : Square Hole

Color : Golden

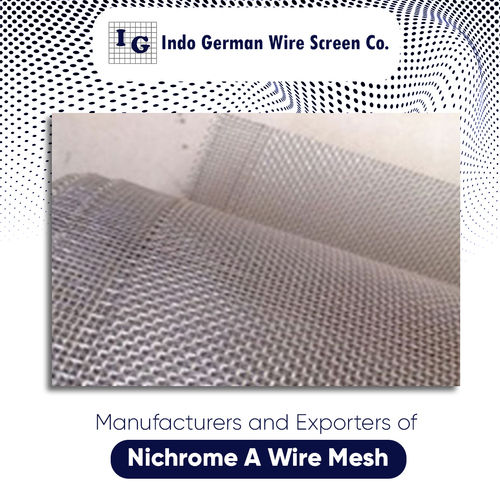

Nichrome Wire Mesh

Minimum Order Quantity : 10 Square Foots

Mesh Style : Other , Woven

Product Type : Wire Mesh

Hole Shape : Square Hole

Color : Sliver

Aluminium 5052 Wire Mesh

Price 8.8 INR

Minimum Order Quantity : 10 Square Foots

Mesh Style : Other , Woven

Product Type : Wire Mesh

Hole Shape : Square Hole

Color : Sliver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry