Aluminum Plain Weave Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Aluminum Plain Weave Wire Mesh Specification

- Wire Gauge

- Available in standard gauges such as 18, 20, 22, 24 SWG

- Hole Shape

- Square

- Length

- Standard rolls of 30 meters, customized lengths available

- Surface Treatment

- Coated

- Aperture

- Typically ranges from 0.5 mm to 10 mm depending on mesh count

- Product Type

- Wire Mesh

- Mesh Type

- Plain Weave

- Mesh Style

- Plain Mesh

- Material

- Aluminum

- Alloy

- Typically 1100, 3003 or 5056 aluminum alloy

- Application

- Other

- Dimensions

- Standard widths: 1 meter, 1.2 meter; Custom sizes possible

- Wire Diameter

- Ranges from 0.3 mm to 2 mm

- Weight

- Lightweight, depends on gauge and mesh count

- Color

- Silver

Aluminum Plain Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Aluminum Plain Weave Wire Mesh

AluminumWire Mesh is a first choice for a wide range of industries including marine, automotive, aerospace, and electrical conductivity applications. Aluminumalloys contain magnesium whose addition makes alloy hard and offers good corrosion resistance in marine atmospheres andmost commonly used in petrochemical and food processing, chemical, plastic production houses, on the other hand, coarserAluminumPlain Weave Wire Meshweaves are used for dewatering, sizing, filter cloth and extruding applications.These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards.we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.Superior Corrosion Prevention

Aluminum Plain Weave Wire Mesh provides exceptional resistance against corrosion, especially in humid or outdoor environments. This makes it a preferred choice for architectural and industrial projects where durability and longevity are critical. The natural oxide layer of aluminum, enhanced with protective coatings, ensures long-term performance without significant maintenance.

Customization and Versatility

Available in various wire gauges, mesh counts, and finishes, this mesh can be tailored to specific requirements for filtration, security, or decorative purposes. Options include standard widths of 1 or 1.2 meters, custom sizes, and different wire diameters, ensuring a precise match for every project. Both OEM and custom solutions are supported.

Reliable Strength and Lightweight Design

Manufactured using alloy grades such as 1100, 3003, and 5056, these meshes balance good tensile strength with low weight, simplifying installation and handling. Suitable for high-temperature environments (up to 600C), these meshes retain their structural integrity in challenging conditions, making them dependable for demanding industrial applications.

FAQs of Aluminum Plain Weave Wire Mesh:

Q: How is the open area percentage of the Aluminum Plain Weave Wire Mesh determined?

A: The open area percentage depends on mesh count, wire diameter, and the weaving pattern. Typically, it ranges from 30% to 75%, which influences airflow, visibility, and filtration rate. Higher mesh counts and finer wires generally result in lower open area.Q: What are the main uses of this aluminum mesh?

A: This mesh is widely used for filtration in industrial processes, insect screens for windows and doors, architectural facades, security enclosures, and various custom applications requiring strength, corrosion resistance, and aesthetic appeal.Q: Where can Aluminum Plain Weave Wire Mesh be installed?

A: It is suitable for both indoor and outdoor locations, including residential, commercial, and industrial settings. Its corrosion resistance makes it ideal for humid or marine locations and areas exposed to weather.Q: How is the mesh shipped and packed?

A: Standard packing includes rolls wrapped in moisture-proof paper and woven bags to protect against damage and moisture during transit. Cut-to-size sheets are also available, packed according to client requirements.Q: What customization options are available?

A: Customers can request specific mesh counts, wire gauges (1824 SWG), alloy types, roll lengths, widths, edge finishes (plain or selvedged), surface treatments, and aperture sizes. OEM and tailor-made solutions are provided based on individual project needs.Q: What benefits do selvedged edges offer over plain edges?

A: Selvedged edges provide a finished side that resists unraveling and increases durability during handling and installation. This is especially important for structural and architectural uses where clean, robust edges are desired.Q: What is the typical process for ordering this wire mesh from a manufacturer or supplier?

A: Start by specifying your requirements such as mesh count, dimensions, wire diameter, edge finish, and any treatment or alloy needed. The supplier will confirm availability or propose a customized solution, after which production and packing are arranged for timely export or delivery.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Aluminium Plain Weave Wire Mesh Category

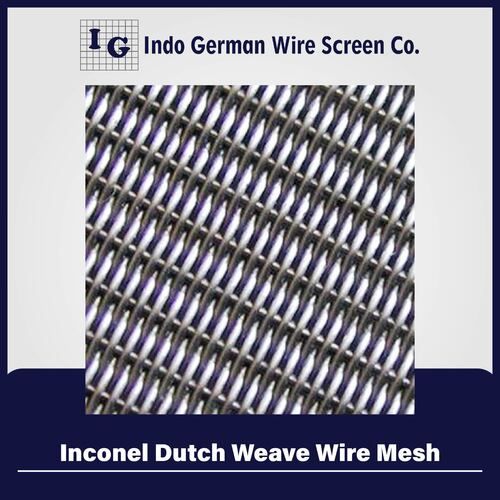

Inconel Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Other

Material : Other, Inconel

Surface Treatment : Coated, Powder Coating

Color : Gray

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry