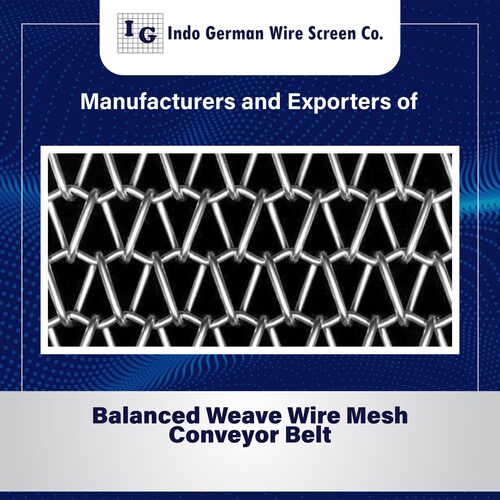

Balanced Weave Wire Mesh Conveyor Belt

Price 1000-100000.00 INR/ Foot

Balanced Weave Wire Mesh Conveyor Belt Specification

- Aperture

- 4 mm to 50 mm

- Surface Treatment

- Galvanized / Polished

- Hole Shape

- Rectangular

- Wire Gauge

- 2 mm to 10 mm

- Length

- Up to 30 m

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Balanced Weave

- Material

- Steel

- Alloy

- High-grade Steel

- Application

- Conveyor Belt for Industrial Applications

- Dimensions

- Custom as per requirements

- Wire Diameter

- 2 mm 10 mm

- Weight

- As per size and design

- Color

- Silver

- Packing Type

- Rolls / Cut Lengths

- Tensile Strength

- High

- Corrosion Resistance

- Excellent (Depending on Surface Treatment)

- Open Area

- 60% 85%

- Belt Pitch

- 10 mm 60 mm

- Standard Widths

- 300 mm 2,000 mm

- Wire Type

- Crimped / Flat Wire

- Operating Temperature Range

- -30C to 350C

- Edge Finish

- Welded / Chain Linked

- Load Bearing Capacity

- Heavy Duty

Balanced Weave Wire Mesh Conveyor Belt Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Letter of Credit (L/C), Paypal, Cheque, Telegraphic Transfer (T/T), Cash in Advance (CID)

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Balanced Weave Wire Mesh Conveyor Belt

We are one of the renowned and reliable manufacturers, supplier, stockist and exporter of Balanced Weave Wire Mesh Conveyor Belt in Mumbai, India.The Balanced weave wire mesh conveyor belt is most commonly used wire mesh Conveyor belt worldwide including many food processing applications ( potatoes drain on it, vegetables are washed on it and products cool on it, etc.) and in industries ranging from glass ceramic, and metal working and is available in best quality Stainless Steel and Carbon Steel Wire mes

Product details.

|

Maximum Wire Operating Temperature |

Fire and heat resistance |

|

Usage/Application |

for wire mesh Conveyor belt |

|

Type |

Industrial |

|

Material |

SS & Carbon |

|

Color |

Black / SS Polished |

Superior Strength and Durability

This conveyor belt features a balanced weave pattern and high-grade steel construction, ensuring formidable tensile strength and resistance to heavy-duty loads. Its robust design allows for consistent performance in demanding industrial settings and ensures a long service life despite challenging operating conditions.

Versatile Design for Multiple Applications

Available with welded or chain-linked edge finishes, and customizable dimensions to fit various conveyor systems, this wire mesh belt supports a wide range of industrial processes, from baking to metallurgy. Its open area (60%85%) enhances airflow and material movement, making it suitable for applications requiring efficient heat transfer and separation.

Corrosion-Resistant Finish

Surface treatments such as galvanizing or polishing are available, providing excellent corrosion resistance tailored to the particular environment. This feature assures reliable operation even under exposure to moisture, chemicals, or extreme temperatures, prolonging belt lifespan and reducing maintenance frequency.

FAQs of Balanced Weave Wire Mesh Conveyor Belt:

Q: How does the balanced weave wire mesh conveyor belt benefit industrial operations?

A: This belt offers high load-bearing capacity, excellent tensile strength, and efficient open area (60%85%), making it ideal for demanding industrial applications. It improves material flow and resists corrosion, supporting uninterrupted processes.Q: What types of surface treatments are available for this conveyor belt?

A: The belt can be treated with galvanized or polished finishes, both of which enhance corrosion resistance according to environmental demands, ensuring reliable and long-term performance.Q: When should I choose a welded versus chain-linked edge finish?

A: Welded edges are recommended for applications that prioritize stability and safety, while chain-linked finishes suit installations where flexibility and custom fit are required. Selection depends on the specific operational needs and conveyor configuration.Q: Where can this conveyor belt be applied within industry?

A: It is designed for a variety of industrial applications, including food processing, metallurgy, ceramics, and advanced manufacturing environments where heavy loads and wide temperature ranges are typical.Q: What is the process for customizing belt dimensions and specifications?

A: Customization involves specifying width (300 mm to 2,000 mm), length (up to 30 m), wire diameter (2 mm to 10 mm), aperture (4 mm to 50 mm), and preferred edge finish. Manufacturers work closely with customers to provide tailored solutions for their specific conveyor systems.Q: How do I use and install the balanced weave wire mesh conveyor belt?

A: The conveyor belt is supplied in rolls or cut lengths. Installation requires securing the belt to the conveyor framework, using the appropriate tension and edge finish for optimal operation. Detailed instructions and support are available from the supplier.Q: What materials and alloy are used in the construction of the mesh belt?

A: Constructed from high-grade steel alloy, with options for crimped or flat wire types, the belt provides superior strength, durability, and corrosion resistance suitable for rigorous industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Black Wire Cloth

Price 14 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Color : Black

Material : Iron

Mesh Type : Other

Product Type : Wire Cloth

Expanded Metal Mesh

Price 30 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Color : Green

Material : Aluminum

Mesh Type : Aluminum Wire Mesh

Product Type : Wire Mesh

Wire Mesh For Food Processing Preparation

Color : Sliver

Material : Stainless Steel

Mesh Type : Iron Wire Mesh

Product Type : Wire Mesh

Galvanized Barbed Iron Wire

Minimum Order Quantity : 100 Kilograms

Color : Silver

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry