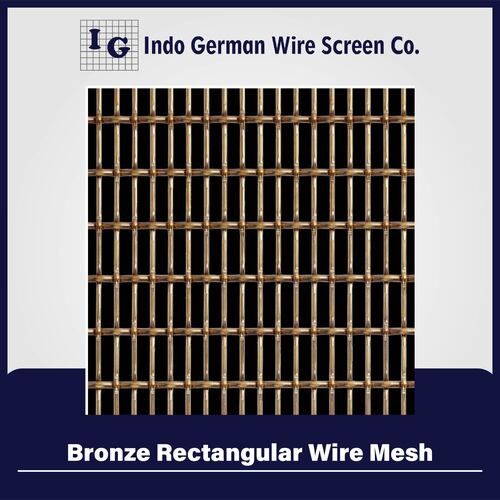

Bronze Rectangular Wire Mesh

Price 50 INR/ Unit

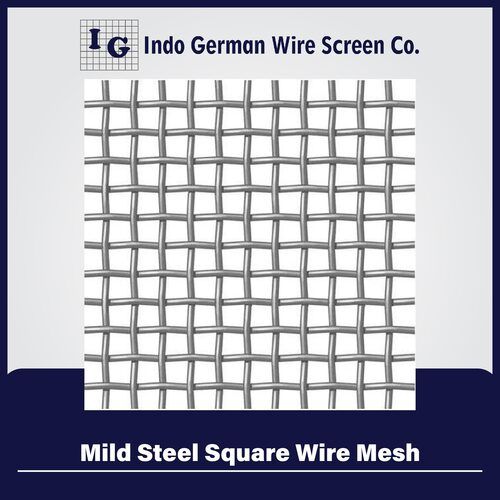

Bronze Rectangular Wire Mesh Specification

- Hole Shape

- Rectangular

- Length

- 30 meters (standard roll), customizable

- Surface Treatment

- Polished, Uncoated

- Aperture

- 1 mm x 3 mm to 5 mm x 100 mm (customizable)

- Wire Gauge

- 10 to 30 SWG

- Product Type

- Wire Mesh

- Mesh Type

- Rectangular Mesh

- Mesh Style

- Woven

- Material

- Phosphor Bronze / Bronze Alloy

- Alloy

- Copper-Tin (Phosphor Bronze)

- Application

- Filtration, Sieving, Decorative Uses, Industrial Screening

- Dimensions

- Custom sizes available, up to 4 feet width

- Wire Diameter

- 0.3 mm to 3 mm

- Weight

- Variable as per size and mesh count

- Color

- Bronze

About Bronze Rectangular Wire Mesh

Bronze is an alloy that consists primarily of copper and has a brownish-red colour. Bronze exhibits many of the same characteristics of copper, like durability, malleability, and ductility. Typically, commercial bronze wire mesh has a material chemical composition of: 90% Copper, 10% Zinc. Bronze is highly resistant to corrosion, fatigue and oxidation and has good electrical conductivity and elasticity due to the fine grain constitution.Bronze Rectangular Wire cloth plain weave is the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.

Superior Corrosion Resistance & Strength

Phosphor bronze wire mesh offers outstanding resistance to corrosion, making it suitable for humid or challenging environments. Its high tensile strength ensures structural integrity and a long service life even under heavy loads or frequent use.

Versatility in Applications

This bronze mesh is extensively used in filtration, sieving, industrial screening, and decorative projects. Its rectangular apertures and various wire gauges make it adaptable for both fine and coarse screening processes across different industries.

Customization for Specific Needs

With options for wire diameter, aperture size, roll width, and mesh style, our wire mesh can be tailored to meet unique project requirements. Whether standard rolls or bespoke dimensions are needed, customization ensures optimal performance.

FAQs of Bronze Rectangular Wire Mesh:

Q: How is bronze rectangular wire mesh manufactured to ensure quality?

A: The mesh is woven using premium phosphor bronze wires in either plain or twill weave patterns, adhering to ASTM and IS standards. Each roll is quality checked for strength, uniform aperture, and finish before being securely packed and shipped.Q: What are the main benefits of using bronze wire mesh in industrial applications?

A: Bronze wire mesh offers excellent corrosion resistance, high tensile strength, and a wide operating temperature range. These properties make it reliable for filtration, sieving, and screening in demanding industrial environments.Q: When should I opt for a customized mesh size or aperture?

A: Customized mesh is recommended when standard dimensions do not meet specific filtration or screening requirements, or when precise sizing is essential for decorative or industrial installations.Q: Where is bronze rectangular wire mesh commonly used?

A: It is widely employed in chemical processing, food and beverage filtration, decorative architectural features, and industrial sieving and screening processes due to its versatility and durability.Q: What is the process for ordering made-to-order wire mesh rolls?

A: Clients can specify their requirementssuch as wire gauge, aperture, roll width, and lengthwhen placing an order. The mesh is then manufactured according to these specifications and packaged for secure delivery.Q: How should bronze wire mesh be maintained for optimal performance?

A: Regular cleaning of the mesh surface helps prevent debris buildup and maintains effective filtration or screening. The polished surface and corrosion resistance reduce maintenance effort, but routine inspection is advised for long-term use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rectangular Wire Mesh Category

Stainless Steel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

Surface Treatment : Coated

Brass Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Golden

Mesh Type : Other , Brass Wire Mesh

Product Type : Wire Mesh

Surface Treatment : Coated

Mild Steel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Type : Steel Wire Mesh

Product Type : Wire Mesh

Surface Treatment : Coated

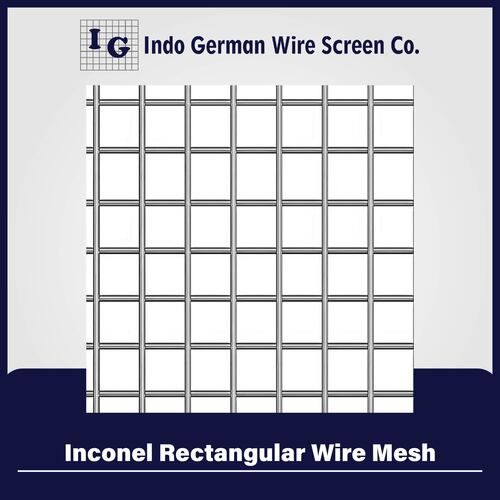

Inconel Rectangular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Mesh Type : Other , Inconel Wire Mesh(

Product Type : Wire Mesh

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry