Bronze Woven Wire Mesh

Price 50 INR/ Unit

Bronze Woven Wire Mesh Specification

- Length

- Standard rolls: 30 meters

- Hole Shape

- Square

- Wire Gauge

- As per requirement

- Surface Treatment

- Coated

- Aperture

- Varies (typically 0.5mm to 6mm)

- Product Type

- Wire Mesh

- Mesh Type

- Woven

- Mesh Style

- Expanded Mesh

- Material

- Bronze

- Alloy

- Commercial Bronze (Copper-Zinc alloy)

- Application

- Other

- Dimensions

- Custom sizes available (Standard width: 1 meter)

- Wire Diameter

- Typically 0.15mm to 1.2mm

- Weight

- Varies by specification (Approx. 5-20 kg/roll)

- Color

- Bronze

- Opening Rate

- Up to 78%

- Corrosion Resistance

- High

- Edge Finish

- Cut or selvage

- Packing

- Wrapped in plastic, then in wooden cases

- Temperature Resistance

- Up to 260°C

- Certificates

- ISO 9001:2015

- Usage

- Filtration, architectural decoration, shielding, sieving, insect screens

- Weave Type

- Plain weave

- Tensile Strength

- Excellent

Bronze Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Bronze Woven Wire Mesh

Bronze is an alloy that consists primarily of copper and has a brownish-red colour. Bronze exhibits many of the same characteristics of copper, like durability, malleability, and ductility. Typically, commercial bronze wire mesh has a material chemical composition of: 90% Copper, 10% Zinc.Bronze Woven Wire Mesh or wire clothis technically a wire mesh panel accurately manufactured by, woven to size in the same technique cloth is woven, manufactured on a loom. It is particularly useful because it works perfectly with hot or cold liquids, is extremely chemical resistant, and can be easily cleaned.Bronze Woven Wire nettingis normally woven on looms, like looms that are normally used to weave cloth.Bronze Woven Wire Meshesare exceptionally multipurpose and adaptable and easy to install, and are used in numerous applications. Heavier Bronze Woven Wires must be pre-crimped as the material rests stable and rigid after the crimping process. Whereas pre-crimped Bronze Woven Wire mesh is ideal for both industrial & architectural applications.

Versatile Solutions for Industrial and Decorative Needs

Bronze Woven Wire Mesh provides high corrosion resistance and excellent tensile strength, making it ideal for filtration, architectural facades, sieving, insect screens, and electromagnetic shielding. Its elegant bronze color and customizable mesh style allow it to seamlessly blend functional and decorative roles, delivering performance with aesthetic appeal.

Precision Manufacturing and Robust Packaging

Each mesh roll is manufactured to strict ISO 9001:2015 standards, ensuring consistent quality. Available in various wire gauges and apertures, the mesh can be tailored to specific project requirements. To guarantee protection during transport, the mesh is wrapped in plastic and securely packed in sturdy wooden cases.

FAQs of Bronze Woven Wire Mesh:

Q: How is bronze woven wire mesh typically used in filtration and architectural applications?

A: Bronze woven wire mesh is widely employed in filtration systems for liquids and gases due to its high corrosion resistance and temperature tolerance. In architecture, it is favored for its decorative appeal and shielding properties, making it suitable for facades, partitions, and protective screens.Q: What processes are involved in manufacturing plain weave bronze wire mesh?

A: The mesh undergoes a weaving process where bronze wires are interlaced in a classic plain weave pattern. After weaving, the mesh may be coated for additional surface protection and cut to size or finished with selvage edges, ensuring durability and clean edges.Q: When should I choose bronze wire mesh over other materials?

A: Opt for bronze wire mesh when you need superior corrosion resistance in moist or marine environments, require non-sparking properties, and seek an attractive finish for visible or decorative installations.Q: Where can I use bronze woven wire mesh for shielding purposes?

A: Bronze mesh is suitable for electromagnetic or radio-frequency shielding in sensitive environments such as laboratories or electronics enclosures due to its conductive properties and precision weaving.Q: What are the benefits of selecting a mesh with a high opening rate (up to 78%)?

A: A high opening rate allows for efficient airflow, light transmission, or rapid filtration, making the mesh ideal for sieving, insect screens, and filter applications where both separation and permeability are essential.Q: How is the wire mesh packaged for export or local delivery?

A: To ensure the mesh arrives in optimal condition, each roll is wrapped in protective plastic and then placed in strong wooden cases. This minimizes damage during transit and maintains product quality.Q: Can the dimensions and aperture of the mesh be customized for specific projects?

A: Yes, bronze woven wire mesh can be produced in custom widths, lengths, apertures, and wire diameters to meet diverse industrial, commercial, or architectural requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Expanded Mesh Category

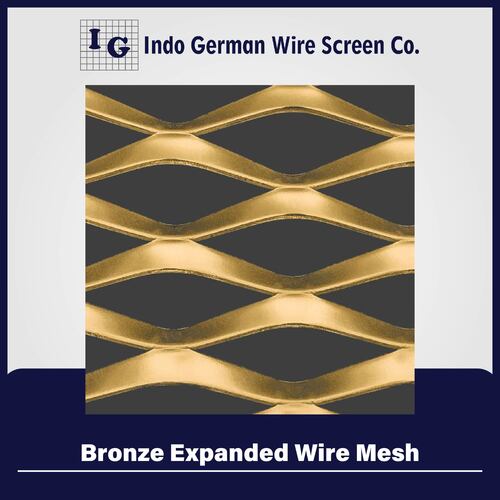

Bronze Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Bronze

Surface Treatment : Coated

Mesh Style : Expanded Mesh

Material : Other, Bronze

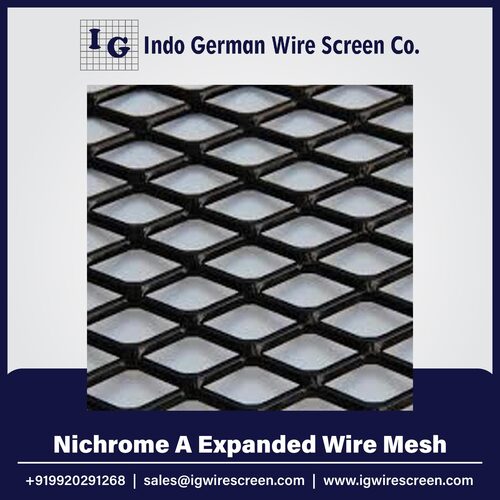

Nichrome A Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Other, Uncoated

Mesh Style : Other , Expanded

Material : Other, Nichrome A

Nickel Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Polished

Mesh Style : Other , Expanded

Material : Other, Nickel

Steel Expanded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Mesh Style : Expanded Mesh

Material : Steel

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry