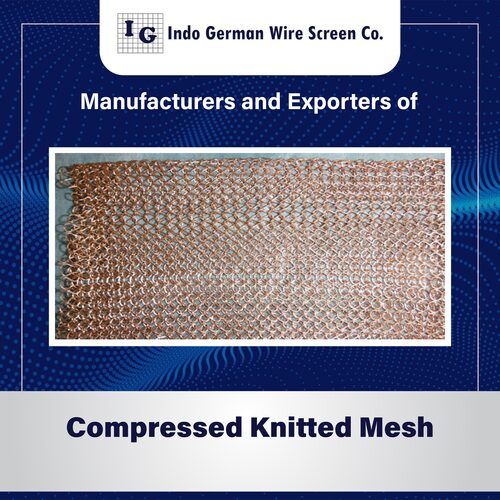

Compressed Knitted Mesh

Compressed Knitted Mesh Specification

- Surface Treatment

- Polished

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Type

- Copper Wire Mesh

- Mesh Style

- Knitted Wire Mesh

- Material

- Copper

- Color

- Brass

About Compressed Knitted Mesh

This extraordinary stuff, which has been meticulously and passionately crafted, is intended to raise the bar on your regular encounters. Our Compressed Knitted Mesh is unique in its ability to combine strength and flexibility. It has an elaborate knitted design made from high-grade, premium yarns that offer durability and breathability. To improve its structural integrity and ensure that it will endure the test of time, this mesh is meticulously compacted. Our Compressed Knitted Mesh has countless uses, whether you are a DIY or fashion enthusiast.

Product details

|

Country of Origin |

Made in India |

|

Material |

SS304 |

|

Material Grade |

304,316 and others |

|

I Deal In |

New Only |

|

Type |

Compressed Knitted Mesh |

|

Usage/Application |

Industrial |

Precision Knitted Copper Mesh for Industrial Excellence

Our copper wire mesh, meticulously knitted and compressed, stands out for its robustness and uniform square holes. The polished surface enhances anti-corrosive properties and makes it suitable for sensitive environments. The brass color finish not only offers an appealing look but also acts as a protective layer. Perfect for filtration, EMI shielding, and separation processes, our mesh meets the highest standards in quality and performance.

India-Based Exporter and Supplier of Advanced Mesh Solutions

Operated from India, we serve national and international markets as a trusted exporter, manufacturer, supplier, and trader of copper knitted mesh. Our state-of-the-art production infrastructure ensures each mesh batch complies with rigorous quality controls. We address various industry needs by customizing mesh specifications, helping clients optimize their systems and improve operational efficiency with our reliable copper wire mesh products.

FAQs of Compressed Knitted Mesh:

Q: How is the compressed knitted copper wire mesh manufactured?

A: The mesh is created by interlocking copper wires in a knitted pattern, then compressing them to achieve the desired density and structure. After knitting, the mesh is polished, resulting in a durable, corrosion-resistant surface and an attractive brass finish.Q: What are the typical uses for this polished copper knitted mesh?

A: This mesh is commonly used for filtration, EMI/RFI shielding, demisting, gasketing, recycling, and particle separation in industrial and electronic applications due to its excellent conductivity and resistance to corrosion.Q: Where can the copper knitted mesh with square holes be installed?

A: It is suitable for use in industrial plants, electronic assembly units, automotive exhaust systems, filtration equipment, and architectural projects, wherever robust screening and filtering are required.Q: When should I choose copper knitted mesh over other mesh types?

A: Choose copper knitted mesh when you require superb electrical conductivity, flexibility, corrosion resistance, and the ability to withstand both mechanical stresses and environmental factors.Q: What is the process of surface polishing for this mesh?

A: After knitting and compressing, the copper mesh undergoes a specialized polishing process. This treatment improves the meshs surface smoothness, enhances corrosion resistance, and gives it a distinctive, clean brass color.Q: How does using copper mesh benefit my application?

A: Copper mesh provides high strength, long-term reliability, anti-corrosive characteristics, and electrical conductivity, making it advantageous for critical industrial applications and elevating both performance and longevity of your systems.Q: What makes your company a reliable supplier and exporter from India?

A: We combine advanced manufacturing practices, strict quality controls, and prompt customer service, ensuring our copper knitted mesh consistently meets our clients specifications and industry standards for both domestic and international orders.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Knitted Wire Mesh Category

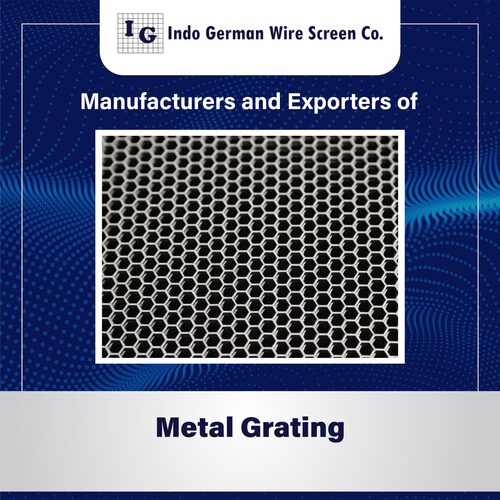

Metal Grating

Hole Shape : Other , Rectangular

Material : Iron

Wire Gauge : Customizable as per requirement

Weight : Varies depending on panel size and wire gauge

Application : Other, Industrial flooring, walkway platforms, trench covers, stair treads, structural support

Aperture : 25 mm x 100 mm (standard), customizable

Ginning Knitted Mesh

Hole Shape : Other , Rectangular

Material : Stainless Steel

Wire Gauge : 0.15 mm to 0.28 mm

Weight : Lightweight (Varies as per size)

Application : Other, Ginning Machine, Filtration, Dust Removal

Aperture : 2 mm to 3 mm

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry