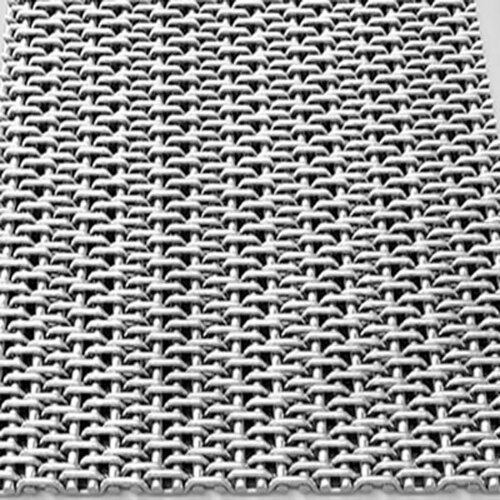

Copper Dutch Weave Wire Mesh

Price 50 INR/ Unit

Copper Dutch Weave Wire Mesh Specification

- Hole Shape

- Rectangular

- Surface Treatment

- Coated

- Length

- 30 Meter Roll

- Aperture

- 0.08 mm

- Wire Gauge

- 32 Gauge

- Product Type

- Wire Mesh

- Mesh Type

- Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Copper

- Alloy

- Pure Copper

- Application

- Other

- Dimensions

- Width 1 Meter

- Wire Diameter

- 0.20 mm

- Weight

- 6 kg per roll

- Color

- Gray

Copper Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Copper Dutch Weave Wire Mesh

Copper is ductile, malleable and has high thermal and electrical conductivity. Copper is resistant to atmospheric corrosion but is attacked by oxidizing agents such as nitric acid, ferric chloride, and ammonia acid compounds. Copper when exposed to the atmosphere will naturally develop a thin green layer, known as patina.Copper is anti-sparkling in nature, has low tensile strength, is deprived of wear and tears and they darken after some time. Copper exhibits a white or silver, easy to clean surface.Copper dutch weave wire meshis widely utilized as filter fittings for chemical industry, medicine, petroleum, and scientific research units due to its stable and fine filtration ability.

Exceptional Filtration Precision

Utilizing Dutch Plain Weave technology, this copper wire mesh provides an ultra-fine 0.08 mm aperture, ensuring effective separation of even minute particles. Widely used in filtration and sieving processes across industries, its pure copper construction combines both longevity and high filtration efficiency, making it suitable for intricate and demanding applications.

Durability and Corrosion Resistance

Boasting superior corrosion resistance, the mesh is coated to withstand harsh environments and corrosive agents, ensuring a long lifespan. Its temperature resistance up to 200C allows for effective operation in both moderate and elevated temperature processes, providing reliability where other materials might fail.

Versatile Roll Form Convenience

Available in user-friendly 30-meter rolls with a width of 1 meter, this mesh offers flexibility and ease of installation for a range of industrial applications. Its soft, annealed structure enables straightforward cutting, shaping, and fitting, streamlining your workflow without compromising mesh integrity.

FAQs of Copper Dutch Weave Wire Mesh:

Q: How is the Copper Dutch Weave Wire Mesh typically used in industrial settings?

A: This mesh is commonly utilized for fine filtration and sieving tasks in industries such as chemical processing, pharmaceuticals, and food production. Its fine apertures effectively separate small particles, making it indispensable where precision filtration is required.Q: What are the main benefits of choosing copper mesh with a Dutch Plain Weave for filtration?

A: The Dutch Plain Weave offers a robust yet fine mesh structure, enhancing filtration accuracy and mesh strength. Coppers natural corrosion resistance and thermal conductivity further extend the meshs lifespan and performance under varying operating conditions.Q: When should I use a mesh with an 80-micron opening and 32 gauge wire?

A: An 80-micron mesh with a 32 gauge (0.20 mm) wire is ideal when you need to filter or sieve extremely fine particles. Its suitable for situations demanding high precision, such as in laboratory filtration, water purification, and sensitive industrial processes.Q: What is the recommended process for installing this wire mesh roll?

A: Start by measuring and cutting the mesh to your required size using suitable tools for copper material. The soft, annealed property allows for easy handling. Secure the mesh in your filtration system or installation frame, ensuring a tight, wrinkle-free fit for optimal performance.Q: Where can this copper wire mesh be sourced, and who supplies it?

A: This product is available from credible exporters, manufacturers, suppliers, and traders in India. For bulk or specialized requirements, contact a verified Indian supplier to ensure you receive authentic, high-quality copper wire mesh rolls.Q: How does the coated surface treatment enhance the meshs usability?

A: The coated surface acts as an additional protective layer, enhancing resistance to oxidation and extending the meshs durability, especially in aggressive or humid environments, making it more reliable for long-term industrial filtration use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dutch Weave Wire Mesh Category

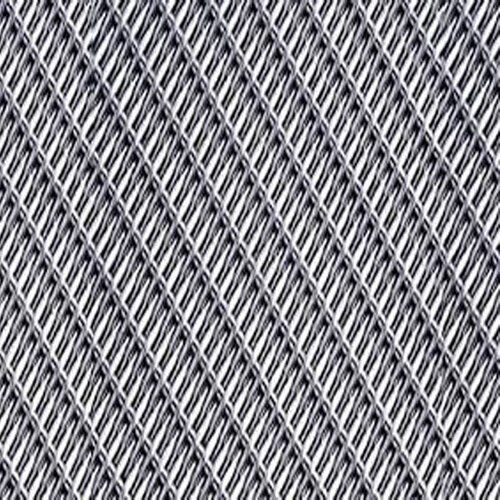

Steel Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Material : Steel

Color : Gray

Surface Treatment : Coated

Stainless Steel Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Material : Stainless Steel

Color : Gray

Surface Treatment : Coated

Iron Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Dutch Weave Wire Mesh

Material : Iron

Color : Gray

Surface Treatment : Coated

Mild Steel Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Dutch Weave Wire Mesh

Material : Other, Mild Steel

Color : Gray

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry