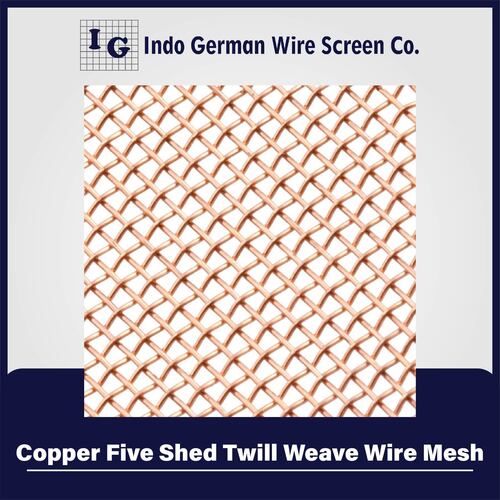

Copper Five Shed Twill Weave Wire Mesh

Price 50 INR/ Unit

Copper Five Shed Twill Weave Wire Mesh Specification

- Wire Gauge

- 34 Gauge

- Aperture

- 0.18 mm

- Hole Shape

- Square

- Surface Treatment

- Coated

- Length

- 15 Meter

- Product Type

- Wire Mesh

- Mesh Type

- Five Shed Twill Weave

- Mesh Style

- Plain Mesh

- Material

- Steel

- Alloy

- Copper

- Application

- Other

- Dimensions

- 1 meter x 15 meter

- Wire Diameter

- 0.022 mm

- Weight

- Approx. 8 kg per roll

- Color

- Copper

Copper Five Shed Twill Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Copper Five Shed Twill Weave Wire Mesh

Copper is ductile, malleable and has high thermal and electrical conductivity. Copper is resistant to atmospheric corrosion but attacked by oxidizing agents such as nitric acid, ferric chloride

and ammonia acid compounds. Copper when exposed to the atmosphere it will naturally develop a thin green layer, known as patina. Copper

s unique colour makes it a very popular option for many different types of users including designers, artists, architects and homeowners.

Copper Five Shed Twill weave wire meshis a welded wire mesh panel precisely manufactured by knitting thin diameter wires to form a square mesh hole. TheCopper Five Shed Twill weave wire meshcloth is also exceptionally strong with good dewatering qualities and high flow rates.Copper Five Shed Twill Weave Wire Mesh could be Woven and Welded. We offer an exclusive range ofCopper Five Shed Twill Weave Wire Meshat unmatched quality and market leading prices.

Premium Five Shed Twill Weave Construction

This mesh uses a five shed twill weave, delivering enhanced durability, flexibility, and a uniform structure. Its intricate pattern ensures precise aperture sizes of 0.18 mm, making it highly suitable for delicate filtration or separation processes. The combination of a copper alloy and steel substrate further elevates its performance in challenging environments.

Exceptional Durability and Resistance

With a high tensile strength of 350 N/mm and temperature resistance up to 250C, this mesh is designed to withstand extreme industrial conditions. Its superior corrosion resistance enables reliable performance in humid and chemically aggressive settings, providing longevity and reduced maintenance needs.

Versatile Dimensions and User-Friendly Packaging

Supplied in 1 meter x 15 meter rolls and weighing approximately 8 kg, this mesh is easy to handle, store, and install. The plain or selvage edge options, combined with ASTM-compliant packagingincluding polybag wrappingensure safe transportation and pristine delivery, ready for use in diverse applications.

FAQs of Copper Five Shed Twill Weave Wire Mesh:

Q: How is the five shed twill weave constructed in this mesh?

A: The five shed twill weave is created by passing the wire alternately over and under multiple adjacent wires in a repeating pattern, which increases the meshs strength and flexibility compared to plain weave meshes. This structure results in a more robust, uniform fabric and precise aperture control.Q: What are the main advantages of using Copper Five Shed Twill Weave Wire Mesh?

A: Key advantages include high corrosion and temperature resistance (up to 250C), excellent tensile strength (350 N/mm), fine aperture control, and durability. Its copper-alloy composition ensures longevity in harsh environments, making it ideal for filtration, screening, and separation applications.Q: When should I choose a plain edge versus a selvage edge option?

A: Choose a plain edge when the mesh will be cut to size or used within frames, as its more flexible for customization. Select a selvage edge if you need improved edge stability and reduced fraying, particularly for applications involving tension or frequent handling.Q: Where can this mesh be applied most effectively?

A: This mesh is suitable for use in filtration, chemical processing, sieving, and architectural applications. Its corrosion resistance and fine aperture make it ideal for demanding industrial environments, including laboratories, process plants, and machinery requiring reliable separation solutions.Q: What is the process for packaging and delivering the mesh rolls?

A: After manufacturing and surface coating, the mesh is wound into 1 meter x 15 meter rolls. Each roll, weighing around 8 kg, is carefully wrapped in a polybag and prepared for shipment according to ASTM E2016-20 standards, ensuring safe delivery to locations across India and for export.Q: How do I benefit from the meshs compliance with ASTM E2016-20 standards?

A: Compliance with ASTM E2016-20 assures you of consistent quality, precise mesh specifications, and reliable performance, meeting recognized global standards for wire mesh production and ensuring suitability for critical industrial processes.Q: What makes the copper-coated surface advantageous for industrial use?

A: The copper-coated surface offers high resistance to corrosion and tarnishing, making the mesh ideal for environments prone to moisture or chemicals. It also enhances electrical conductivity and provides an appealing aesthetic for architectural or decorative uses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Five Shed Twill Weave Wire Mesh Category

Stainless Steel Welded Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Mesh Style : Other , Five Shed Twill Weave

Mesh Type : Steel Wire Mesh

Surface Treatment : Coated

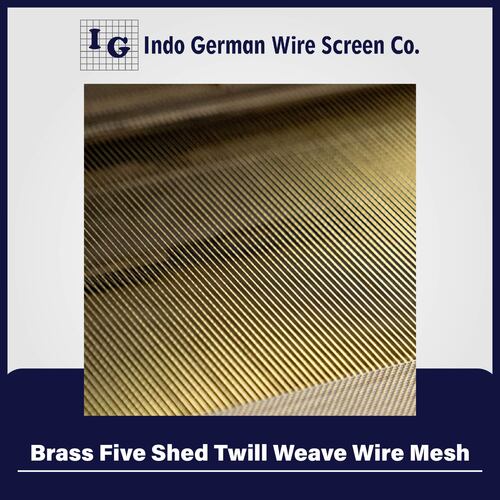

Brass Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Brass

Mesh Style : Plain Mesh

Mesh Type : Other , Five Shed Twill Weave

Surface Treatment : Coated

Steel Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Mesh Style : Plain Mesh

Mesh Type : Steel Wire Mesh

Surface Treatment : Coated

Iron Five Shed Twill Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Iron

Mesh Style : Other , Twill Weave

Mesh Type : Iron Wire Mesh

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry