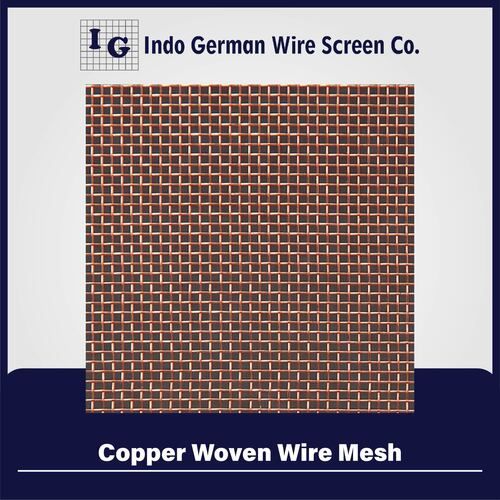

Copper Woven Wire Mesh

Price 50 INR/ Unit

Copper Woven Wire Mesh Specification

- Aperture

- Custom or standard apertures from 0.15 mm to 2 mm

- Wire Gauge

- Standard: 14 Mesh to 200 Mesh

- Surface Treatment

- Coated

- Hole Shape

- Square

- Length

- Available up to 30 meters or customized

- Product Type

- Wire Mesh

- Mesh Type

- Copper Wire Mesh

- Mesh Style

- Woven

- Material

- Copper

- Alloy

- Pure Copper or Copper Alloy options available

- Application

- Other

- Dimensions

- Standard: 1 m x 30 m roll or as required

- Wire Diameter

- Range: 0.15 mm to 2 mm

- Weight

- Varies by gauge and dimensions

- Color

- Copper

Copper Woven Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Copper Woven Wire Mesh

Copper is ductile, malleable and has high thermal and electrical conductivity. Copper is resistant to atmospheric corrosion but attacked by oxidizing agents such as nitric acid, ferric chloride, cya nides, and ammonia acid compounds. Copper when exposed to the atmosphere it will naturally develop a thin green layer, known as patina. Copper is unique colour makes it a very popular option for many different types of users, including designers, artists, architects and homeowners.The mesh itself will remain strong and stable with a high percentage of open area. Different patterns such as plain weave, twilled weave, and plain dutch weave are made on these types of weaving looms.Copper Woven Wires must be pre-crimped as the material rests stable and rigid after the crimping process. Whereas pre-crimped Copper Woven Wire mesh is ideal for both industrial & architectural applications.

Outstanding Electrical Shielding Capabilities

Copper Woven Wire Mesh offers high electrical conductivity, making it particularly effective for electromagnetic (EMI) and radio frequency (RFI) shielding. Its non-magnetic and corrosion-resistant nature ensures long-lasting, reliable protection of sensitive electronic equipment in diverse environments, including industrial, architectural, and research applications.

Versatile Weave Types and Aperture Sizes

Choose from plain or twill weave patterns and customizable aperture sizes between 0.15 mm and 2 mm. This flexibility makes the mesh suitable for precision filtration, architectural enhancements, insect barriers, and technical screening. Wired in gauges from 14 to 200 mesh, it meets the demands of various industries where both aesthetic and functional properties are essential.

FAQs of Copper Woven Wire Mesh:

Q: How is Copper Woven Wire Mesh typically installed or used?

A: Copper Woven Wire Mesh can be installed in frames, panels, or fixed directly to structures, depending on the application. For EMI/RFI shielding, it is often positioned behind walls, floors, or enclosures. In filtration and screening, it is inserted into filter units or windows.Q: What makes this copper mesh suitable for EMI/RFI shielding applications?

A: The high electrical conductivity and tight, woven construction ensure efficient dissipation and blockage of electromagnetic and radio frequency interference, protecting sensitive electronics and communication devices from disruptive noise.Q: When should I choose plain weave versus twill weave copper mesh?

A: Plain weave is ideal for most standard applications, offering a balanced combination of strength and open area. Twill weave provides increased flexibility and accommodates finer wires without sacrificing stability, making it suitable for environments requiring tighter filtration or greater durability.Q: Where can customized dimensions or aperture sizes be requested?

A: Custom sizes and apertures are available directly from the manufacturer or supplier. Orders can be tailored by specifying width, length, aperture, gauge, and weave type at the time of inquiry or purchase.Q: What benefits does copper wire mesh offer over other materials?

A: Copper provides excellent corrosion resistance, superior electrical conductivity, and a non-magnetic profile. These characteristics make it highly advantageous for electrical shielding, filtration, and decorative applications compared to other metals like steel or aluminum.Q: How is the mesh packaged and delivered?

A: Copper Woven Wire Mesh is typically supplied in rolls up to 1 meter by 30 meters or as custom-cut pieces. Packaging is designed to prevent damage during shipping, ensuring the mesh arrives in optimal condition for immediate use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Woven Wire Mesh Material Category

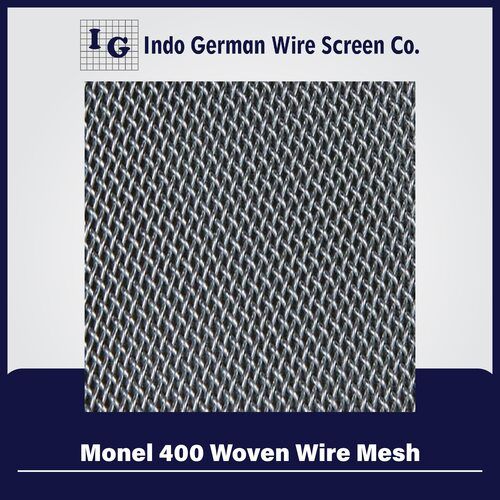

Monel 400 Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Gray

Application : Other

Surface Treatment : Coated

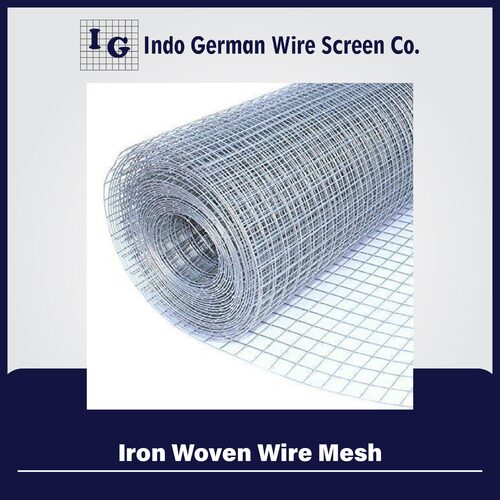

Iron Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Application : Other

Surface Treatment : Coated

Mild Steel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Application : Other

Surface Treatment : Coated

Steel Woven Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Application : Other

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry