Endless Flat Belts

Price 2000 INR/ Meter

Endless Flat Belts Specification

- Surface Finish

- Smooth and uniform

- Features

- High strength, long service life, maintenance free

- Power Source

- Mechanical

- Thickness

- Available in multiple thicknesses, from 2mm and above

- Belt Type

- Flat Endless

- Material

- Iron

- Type

- Endless Flat Belt

- Structure

- Belt

- Belt Conveyor

- Compatible

- Roller Conveyor

- Not compatible

- Resistant Feature

- Abrasion and oil resistant

- Load Capacity

- High, supports various industrial loads

- Speed

- Customizable as per application

- Usage & Applications

- Industrial conveyor systems, material handling, textile, printing, and packaging industries

Endless Flat Belts Trade Information

- Minimum Order Quantity

- 1 Meter

- Supply Ability

- 10 Meters Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Endless Flat Belts

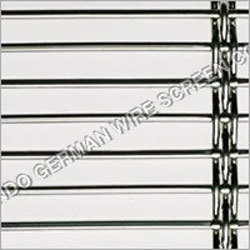

Endless Flat Belts offered by us are widely utilized for the manufacturing of conveyor systems that are intended to be used in various industries. They are made having a perforated structure of very fine mesh size. These belts are chemically inert and find application for material handling, packaging, food processing, and automotive industries. They are corrosion resistant in nature and have a smooth surface finish. Endless Flat Belts manufactured by us have a strong structural configuration with the ability to bear a good amount of load. They assure smooth movement with low power consumption nature. These belts are available at competitive rates in different dimensional configurations as requested by our clients.

Special Features :

- These wear proof belts are reckoned for their good anti slippery attributes and low noise operation.

- Made of thermoset polyurethane with coated surface

- Special cord design inside these belts ensure about their stable dimension

- These belts are widely used in power transmission arena.

Adaptable Design for Industrial Demands

Endless Flat Belts are available in both standard and customized sizes to suit specific requirements. Their unique structure supports various load capacities and usage conditions, making them highly versatile across different industries. Whether for textile machinery or packaging lines, their adaptability enhances operational reliability.

Engineered for Extended Service Life

Made from top-grade iron and finished with smooth, uniform edges, these belts resist abrasion and oilkey factors for longevity in demanding environments. Their high tensile strength ensures consistent performance through repeated cycles, reducing downtime and maintenance costs for businesses.

Installation Made Simple

These belts are designed for easy installation and replacement, streamlining maintenance processes and minimizing system interruptions. Their flexibility makes them suitable for small pulley diameters, and users can select from cut or sealed edges depending on the applications requirements.

FAQs of Endless Flat Belts:

Q: How can Endless Flat Belts be customized to fit specific conveyor system applications?

A: Endless Flat Belts are offered in both standard and tailor-made widths and lengths, allowing precise adaptation to your conveyor systems requirements. You can specify dimensions, edge type, thickness, and color for optimal performance.Q: What industries typically benefit from using Endless Flat Belts?

A: These belts are widely used in industrial conveyor systems, material handling, textile, printing, and packaging industries, where their high load capacity, durability, and maintenance-free design deliver reliable results.Q: When should I choose a sealed edge versus a cut edge for my flat belt?

A: Sealed edges are recommended for applications requiring extra protection against fraying and contaminants, while cut edges suit environments where cost-efficiency or specific installation needs are prioritized.Q: Where are Endless Flat Belts installed within industrial workflows?

A: Endless Flat Belts are installed in conveyor systems, particularly in belt conveyors, for moving materials or products efficiently between workstations or throughout production lines; they are not suitable for roller conveyors.Q: What is the installation process for Endless Flat Belts and how easy is it to replace them?

A: Installation involves placing the belt over compatible pulleys and tensioning it according to application requirements. Their design simplifies replacement, enabling quick swaps without complex procedures or tools.Q: How does the belts resistance to oil and abrasion benefit its operation in industrial environments?

A: Oil and abrasion resistance help preserve belt integrity, prevent wear, and avoid premature failure. This ensures stable operation, extends service life, and reduces maintenance frequency in challenging industrial settings.Q: What are the key advantages of using Endless Flat Belts over other belt types for industrial material handling?

A: Endless Flat Belts provide high flexibility for small pulleys, exceptional tensile strength, adaptability to various applications, extended service life, and easy maintenance, making them ideal for demanding material handling tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Belts Category

Flex Plate Wire Mesh Belt

Price Range 1000.00 - 100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Structure : Other, Flexible Plate Mesh

Resistant Feature : Heat Resistant

Surface Finish : Silver / Polished

Metal Conveyor Belts

Price Range 250.00 - 750.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Structure : Belt

Resistant Feature : Other, Corrosion and heat resistant

Surface Finish : Galvanized / Powder Coated

Mesh Decorative Conveyor Belt

Price 250 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Structure : Belt

Resistant Feature : Other, Corrosion & Heat Resistant

Surface Finish : Polished

Flat Wire Conveyor Belt

Price 1000 INR / Foot

Minimum Order Quantity : 1000 Feet

Structure : Other, Wire Mesh Belt with Side Chains

Resistant Feature : Other, Heat & Corrosion Resistant

Surface Finish : Polished

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry