Food Conveyor Belt

Price 1000 INR/ Foot

Food Conveyor Belt Specification

- Power Source

- Electric

- Thickness

- 3-5 mm

- Belt Type

- Modular/Flat Belt

- Surface Finish

- Polished

- Features

- Smooth Operation, High Durability, Easy Cleaning

- Material

- Food Grade Stainless Steel

- Type

- Belt Conveyor

- Structure

- Frame Structure

- Belt Conveyor

- Yes

- Product Type

- Heat resistance

- Roller Conveyor

- No

- Color

- Steel

- Vertical Conveyor

- Optional

- Pneumatic Conveyor

- No

- Resistant Feature

- Heat Resistant

- Load Capacity

- 50-100 kg per meter

- Voltage

- 220V-380V

- Power

- 1.5 kW

- Speed

- 0.5-2 m/s

- Usage & Applications

- Food Processing, Packaging, Ingredient Transfer

Food Conveyor Belt Trade Information

- Minimum Order Quantity

- 10 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Paypal, Letter of Credit (L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Food Conveyor Belt

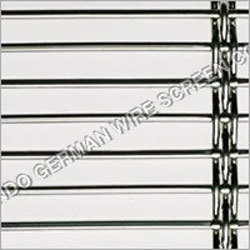

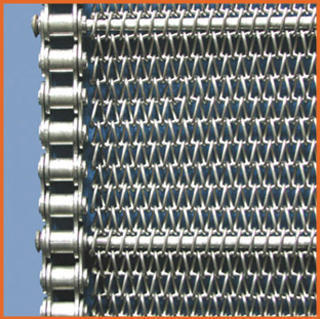

We are one of the renowned and reliable manufacturers, supplier, stockist and exporter of Food grade wire mesh conveyor belt in Mumbai, India.These wire mesh are available in best quality Stainless Steel and Carbon Steel material with different weave type i.e. Plain weave wire mesh conveyor belt, Plain crimp wire mesh conveyor belt, Dutch weave wire mesh conveyor belt, Inter crimp wire mesh conveyor belt, Twill weave wire mesh conveyor belt.

Heat-Resistant and Hygienic Design

Crafted from food-grade stainless steel, the conveyor belt is both heat-resistant and compliant with food safety standards. The polished surface finish and modular/flat belt structure ensure smooth material transport and easier cleaning, supporting manual or CIP sanitation methods.

Flexible Control and Customization

Operators can choose from PLC or manual control systems, adapting operation to specific workflows. With customizable options for length, width, height, and speed, the conveyor belt seamlessly integrates into existing production lines. Floor-mounted installation guarantees stability and efficient space utilization.

Safety and Operational Efficiency

Safety guards and an emergency stop mechanism safeguard workforce wellbeing. Running on electric power (1.5 kW, 220V-380V), this conveyor supports continuous processing with a low noise profile and reliable speed (0.5-2 m/s). Its high load capacity and smooth operation optimize performance in busy food processing environments.

FAQs of Food Conveyor Belt:

Q: How is the Food Conveyor Belt cleaned and maintained for hygiene?

A: Cleaning can be performed manually or via Clean-in-Place (CIP) systems, both designed to maintain sanitary processing conditions. The food-grade stainless steel structure and polished belt surface facilitate thorough sanitation and easy residue removal.Q: What customizable options are available for the Food Conveyor Belt?

A: Users can tailor the conveyors length, width, height, and speed to their facility requirements. Additionally, you may select between modular or flat belt types, and opt for optional vertical conveyor capability if your process demands elevation handling.Q: Where can this conveyor belt be installed in a production facility?

A: Designed for floor-mounted installation, its suitable for food processing, packaging, and ingredient transfer sections of a facility. Its customizable dimensions and control flexibility ensure it fits seamlessly within various layout configurations.Q: When should emergency safety features be used and what are they?

A: Emergency stop buttons and safety guards should be utilized whenever theres an immediate risk to personnel or equipment. These features are integrated into the conveyor to maximize workplace safety during operation and maintenance.Q: What is the process for controlling and operating the conveyor system?

A: The conveyor can be operated through a PLC-based automated control system or manually, depending on production needs. Speed adjustment and other operational settings are accessible through these control methods, accommodating both sophisticated and simple process flows.Q: What benefits does the conveyor bring to food processing operations?

A: Its heat resistance, low noise operation, and easy cleaning enhance processing speed, product safety, and overall efficiency. High durability and customizable design further support productivity, adapting to varying product types and facility layouts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conveyor Belts Category

Truss Edge Wire Mesh Conveyor Belt

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Type : Other, Wire Mesh Conveyor Belt

Material : HighGrade Stainless Steel

Structure : Other, Truss Edge

Belt Conveyor : Other, Yes

Heavy Duty Conveyor Belt

Price 2200 INR / Square Meter

Minimum Order Quantity : 10 Square Meters

Type : Vertical Conveyor

Material : Mild Steel

Structure : Belt

Belt Conveyor : Other, Yes

Mesh Decorative Conveyor Belt

Price 250 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Type : Belt Conveyor

Material : Stainless Steel

Structure : Belt

Belt Conveyor : Other, Yes

Wire Mesh Conveyor Belts

Price 8000 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Type : Belt Conveyor

Material : Steel

Structure : Belt

Belt Conveyor : Other, Yes

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry