Inconel 601 Wire Mesh

Price 50 INR/ Unit

Inconel 601 Wire Mesh Specification

- Hole Shape

- Square / Rectangular

- Wire Gauge

- 10 SWG - 28 SWG

- Length

- 15 m - 30 m or custom

- Surface Treatment

- Polished / Unpolished

- Aperture

- 0.5 mm to 5 mm

- Product Type

- Wire Mesh

- Mesh Type

- Fine / Coarse

- Mesh Style

- Woven / Welded

- Material

- Inconel 601 (Nickel-Chromium Alloy)

- Alloy

- Inconel 601

- Application

- High temperature filtration, furnace liners, chemical processing, heat treatment

- Dimensions

- Customize up to 4 m width

- Wire Diameter

- 0.5 mm - 2.5 mm

- Weight

- Variable as per size and gauge

- Color

- Metallic grey

- Form

- Roll / Sheet / Panel

- Elongation

- 35% min.

- Maximum Operating Temperature

- Up to 1200C

- Melting Point

- 1370C - 1415C

- Tensile Strength

- min. 650 MPa

- Density

- 8.11 g/cm

- Standards

- ASTM B168, ASTM B166

- Electrical Resistivity

- 1.15 m

- Packing Type

- Bubble wrap / Wooden box / Carton

- Roll Size

- Standard 1 m x 30 m, customizable

- Weaving Type

- Plain, Twill, Dutch

- Corrosion Resistance

- Excellent against oxidation and carburization

- Finish

- Bright / Matte

- Thermal Expansion Coefficient

- 13.3 m/mC

About Inconel 601 Wire Mesh

These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards. At Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers and moreover some of the factors that have consistently fuelled our growth in the national as well as international market.Outstanding Heat and Corrosion Resistance

Engineered for extreme environments, Inconel 601 wire mesh excels in resisting oxidation, carburization, and thermal cycling. Its composition allows it to maintain structural integrity at temperatures as high as 1200C, making it a top choice for furnace construction, heat treatment, and chemical industries.

Customizable to Suit Diverse Applications

Available in standard sizes (1 m x 30 m roll) and customizable up to 4 meters wide, this wire mesh can be tailored in terms of wire diameter, aperture, weaving type (plain, twill, Dutch), and surface finishes. It accommodates various project requirements, whether in woven or welded mesh style, and is supplied as rolls, sheets, or panels.

FAQs of Inconel 601 Wire Mesh:

Q: How is Inconel 601 wire mesh typically used in industrial applications?

A: Inconel 601 wire mesh is widely used for high-temperature filtration, furnace liners, heat treatment baskets, and in chemical processing plants, where its ability to resist thermal and chemical stress is critical.Q: What standards are followed in the manufacturing of Inconel 601 wire mesh?

A: The mesh is manufactured in compliance with ASTM B168 and ASTM B166 specifications, ensuring consistency in quality and performance for both domestic and international markets.Q: When should I choose Inconel 601 wire mesh over stainless steel alternatives?

A: Choose Inconel 601 mesh when your application demands superior oxidation resistance, mechanical strength at high temperatures up to 1200C, and protection against aggressive carburizing or thermal shock environments.Q: Where can Inconel 601 mesh be customized for specific dimensions or applications?

A: This mesh is available for customization from manufacturers, exporters, and suppliers in India, offering tailored options for roll size, wire gauge, mesh type, and surface treatment to meet unique project requirements.Q: What is the process for ordering tailored Inconel 601 wire mesh?

A: Customers can specify dimensions, gauge, aperture, mesh style, and finish. The mesh is then manufactured using precise weaving or welding techniques, and is packed securely in bubble wrap, wooden boxes, or cartons for safe transportation.Q: What are the key benefits of using Inconel 601 wire mesh in high-temperature environments?

A: Key advantages include excellent mechanical strength (min. 650 MPa tensile strength), stable elongation (35% min.), high oxidation and carburization resistance, and operational capability up to 1200C, making it reliable in harsh operating conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

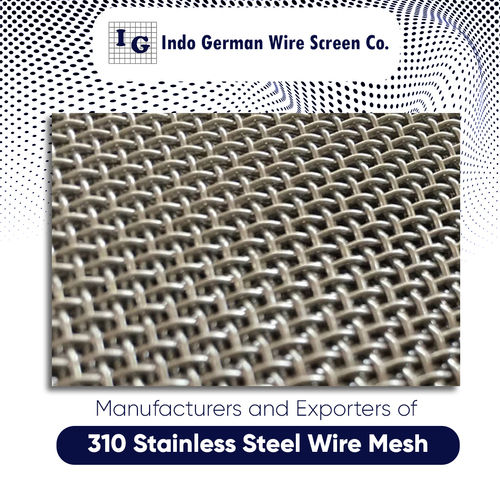

310 Stainless Steel Wire Mesh

Price Range 150.00 - 750.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Product Type : Wire Mesh

Color : Sliver

Surface Treatment : Other, Bright Annealed / Pickled

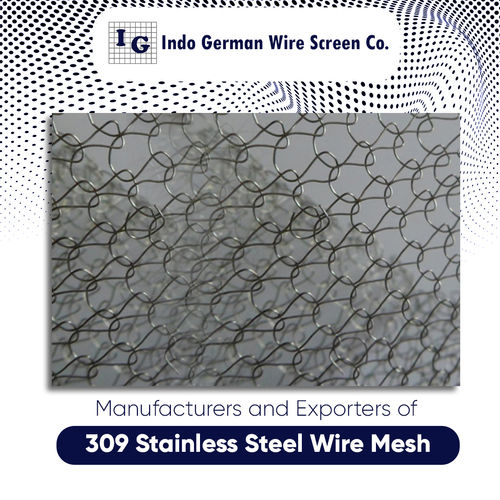

Stainless Steel 309 Wire Mesh

Price Range 220.00 - 750.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Color : Sliver

Surface Treatment : Mill Finish

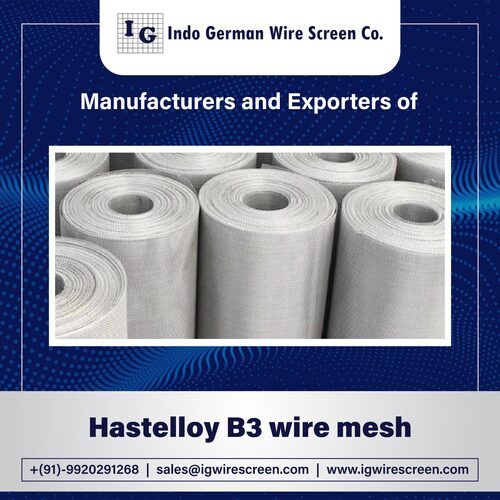

Hastelloy B3 Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Color : Silver

Surface Treatment : Coated

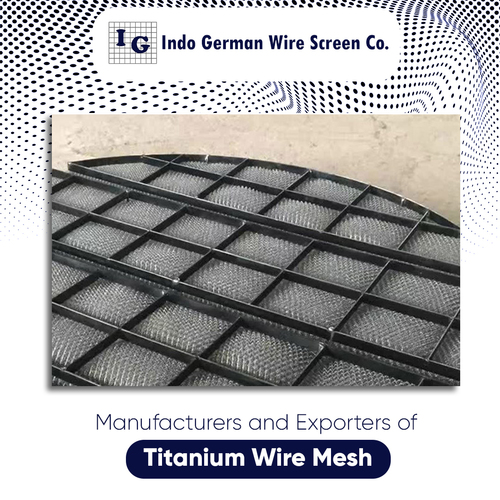

Titanium Wire Mesh

Price Range 2000.00 - 3000.00 INR

Minimum Order Quantity : 10 Square Foots

Product Type : Wire Mesh

Color : Sliver

Surface Treatment : Other, Annealed / Pickled / Polished

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry