Inconel 617 Wire Mesh

Price 100 INR/ Unit

Inconel 617 Wire Mesh Specification

- Surface Treatment

- Coated

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Inconol

- Application

- Other

- Color

- Silver

Inconel 617 Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Inconel 617 Wire Mesh

Inconel 617 Wire Meshis easy to work with and is available in different hole sizes, thickness and other configurations in order to meet your specific application requirements. We offer an exclusive range ofInconel 617 Wire Meshat unmatched quality and market leading prices.

We have become a major supplier of these products into an extensive range of markets and applications across India and the globe. Our clients select our range of products for their economical prices, dimensional preciseness, and high-durability.

Advanced Performance in Harsh Environments

With its high-grade Inconel construction, this wire mesh delivers reliable performance even in the most extreme conditions. The protective surface coating enhances its resistance against oxidation, ensuring extended service life for filtration and separation applications.

Wide Range of Industrial Applications

Inconel 617 Wire Mesh is suitable for various uses, including petrochemical processing, heat exchangers, and energy production facilities. Its square hole design makes it particularly effective in applications requiring uniform filtration and stability.

FAQs of Inconel 617 Wire Mesh:

Q: How is Inconel 617 Wire Mesh different from standard steel mesh?

A: Inconel 617 Wire Mesh provides superior resistance to heat, oxidation, and corrosion, especially at elevated temperatures, compared to standard steel mesh. Its unique alloy composition allows it to maintain structural integrity and performance in challenging industrial environments.Q: What surface treatment is applied to this mesh, and what are its benefits?

A: The Inconel 617 mesh is coated with a specialized surface finish, which enhances its resistance to corrosion and oxidation, extending the products lifespan even when exposed to harsh chemicals and high temperatures.Q: When should Inconel 617 Wire Mesh be chosen over other materials?

A: Select Inconel 617 Wire Mesh when your application demands high strength and excellent resistance to heat and oxidation, such as in chemical processing plants, gas turbines, or high-temperature filtration systems.Q: Where can this mesh be utilized most effectively?

A: This wire mesh is most effective in industries like petrochemicals, energy production, and thermal processing, where durability and resistance to extreme environments are essential. Its plain mesh with square holes ensures efficient and uniform filtration.Q: What is the manufacturing process for Inconel 617 Wire Mesh?

A: The mesh is produced by weaving Inconel 617 wires into a plain mesh configuration with square holes, followed by a coating process that enhances its protective properties. This ensures precision and consistency across the entire mesh.Q: How does the square hole shape benefit industrial applications?

A: The square hole pattern in this mesh offers consistent filtration and flow rates, making it ideal for separation and screening processes. This uniformity helps improve operational efficiency and reliability in industrial systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

Aluminium 6061 Wire Mesh

Price 9 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Polished

Product Type : Wire Mesh

Material : Steel

Nichrome Wire Mesh

Price Range 800.00 - 1200.00 INR

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Other, Bright Annealed

Product Type : Wire Mesh

Material : Steel

314 Stainless Steel Wire Mesh

Price Range 500.00 - 1000.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Other, Mill Finish, or as required

Product Type : Wire Mesh

Material : Steel

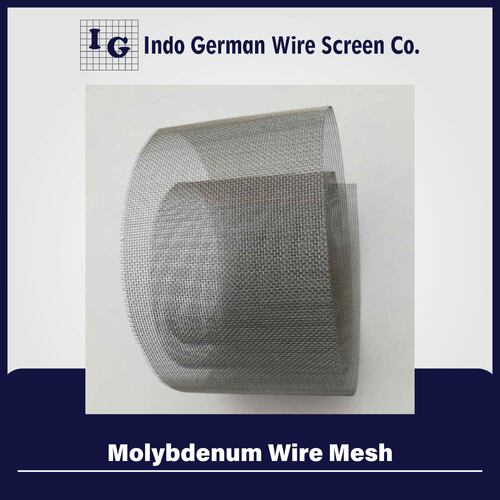

Molybdenum Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other, Cleaned/Bright

Product Type : Other, Woven Wire Mesh

Material : Other, 99.95% pure Molybdenum

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry