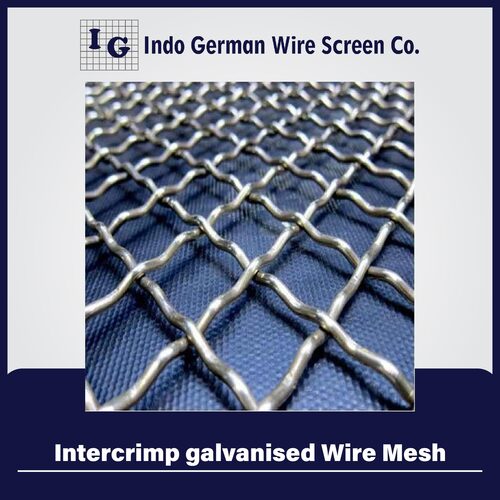

Intercrimp galvanised Wire Mesh

Price 50 INR/ Unit

Intercrimp galvanised Wire Mesh Specification

- Length

- Available in rolls of 30 meters or custom sizes

- Surface Treatment

- Coated

- Hole Shape

- Rectangular/Hexagonal

- Wire Gauge

- Standard gauges available from 1 mm to 5 mm

- Aperture

- Varies from 0.5 inch to 4 inch

- Product Type

- Wire Mesh

- Mesh Type

- Other

- Mesh Style

- Welded Mesh

- Material

- Mild Steel with Galvanized finish

- Alloy

- Non-alloy (Mild Steel)

- Application

- Other

- Dimensions

- Custom sizes and standard sheet sizes

- Wire Diameter

- 1.5 mm to 5 mm

- Weight

- Approx. 10-50 kg per roll, depending on specification

- Color

- Silver

- Manufacturing Process

- Intercrimped welding and galvanizing

- Usage

- Industrial fencing, grills, construction, security enclosures

- Life Expectancy

- Up to 10 years in outdoor conditions

- Edge Type

- Straight and cut edges

- Tensile Strength

- High tensile for reinforcement

- Packing Type

- Plastic wrapped bundles or rolls

- Finishing

- Rust-resistant galvanization

Intercrimp galvanised Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Intercrimp galvanised Wire Mesh

Galvanizing can be done before or after wire mesh is manufactured both in woven form or welded form. Galvanized after woven and galvanized after welded wire mesh is exactly as it sounds. Galvanization of wires prevents corrosion which is most visible at the joint or intersection of galvanized after welded wire mesh specification. Commonly, galvanized wire mesh is specified in applications where relatively large opening sizes are needed.Intercrimp Galvanized Wire Meshis available in different sizes and wide-range can be customized to fit your exact specifications in order to meet your specific application requirements. We offer an exclusive range ofIntercrimp Galvanized Wire Meshat unmatched quality and market leading prices.

Exceptional Durability and Rust Resistance

Engineered for extended outdoor use, the Intercrimp Galvanised Wire Mesh is coated for maximum rust resistance. This treatment not only enhances lifespan but also maintains mesh integrity under various weather conditions. Its mild steel base further ensures a sturdy and resilient structure, making it ideal for demanding industrial applications.

Tailored Dimensions and Versatile Applications

Choose from a wide range of wire gauges, aperture sizes, and roll lengths to suit specific project needs. Whether for security enclosures, fencing, or construction reinforcement, this mesh can be supplied in custom or standard sheets. Its flexibility in manufacturing supports numerous industrial, commercial, and security-related uses.

FAQs of Intercrimp galvanised Wire Mesh:

Q: How does the galvanization process make the wire mesh rust-resistant?

A: The wire mesh is galvanised through a specialized coating process that bonds a layer of zinc to the mild steel. This protective zinc layer acts as a barrier against moisture and air, preventing rust and corrosion even in harsh outdoor environments.Q: What are the main benefits of choosing Intercrimp Galvanised Wire Mesh for fencing or construction?

A: This mesh provides high tensile strength for reinforcement, ensuring long-lasting stability and security. Its rust-resistant finish gives it a lifespan of up to 10 years outdoors, making it a reliable and cost-effective option for industrial fencing, construction, and security enclosures.Q: When should I use straight and cut edge mesh versus other edge types?

A: Straight and cut edges ensure a clean finish and are ideal for applications where precise alignment and a safe, smooth boundary are critical, such as in grills, fences, or secure enclosures.Q: Where can Intercrimp Galvanised Wire Mesh be applied?

A: It is suitable for a wide variety of environments including factories, construction sites, security perimeters, and industrial facilities. Its versatility makes it fit for fencing, grills, construction reinforcement, and security enclosures.Q: What manufacturing processes are involved in producing this mesh?

A: The mesh is fabricated using an intercrimped welding technique followed by galvanization. This process ensures that the wires are securely locked in place and that the entire structure benefits from corrosion protection.Q: How can the mesh be customized for specific project requirements?

A: You can request custom wire diameters (1.55 mm), aperture sizes (0.54 inches), lengths (standard 30m rolls or custom), and sheet dimensions. This flexibility allows the mesh to precisely match your application needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanized Wire Mesh Category

Plain Weave Galvanised Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Type : Other

Material : Galvanized Steel

Surface Treatment : Coated

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry