Low Carbon Steel Wire Mesh

Price 50 INR/ Unit

Low Carbon Steel Wire Mesh Specification

- Wire Gauge

- 1 mm to 10 mm

- Surface Treatment

- Coated

- Length

- 15 to 100 m (customizable)

- Aperture

- 5 mm x 5 mm to 50 mm x 50 mm

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Welded or Woven

- Mesh Style

- Plain Mesh

- Material

- Carbon steel

- Alloy

- Non-alloy

- Application

- Other

- Dimensions

- Custom (as per requirement)

- Wire Diameter

- 0.5 mm to 6 mm

- Weight

- Variable as per size & gauge

- Color

- Gray

Low Carbon Steel Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Low Carbon Steel Wire Mesh

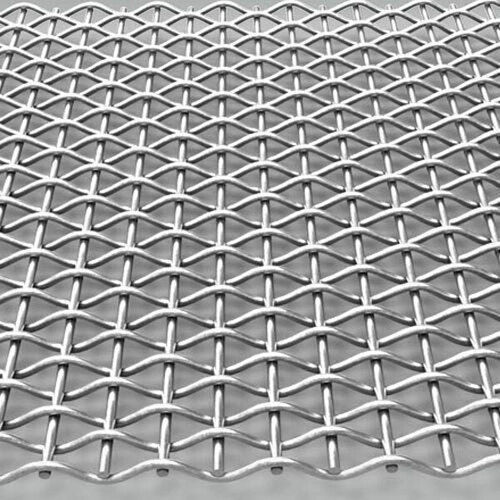

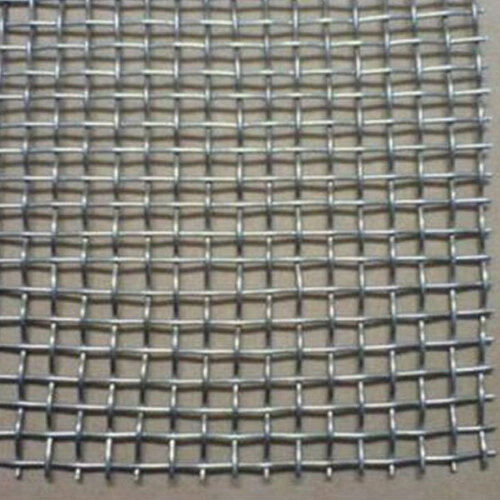

Low Carbon Steel Wire Meshis basically a low cost wire mesh and is a relatively low cost option that is versatile and widely in its use and is generally manufactured in both woven and welded wire mesh specifications.Low Carbon Steel Wire Meshcan be opting to coat a plain steel welded or woven wire mesh.

Low Carbon Steel Wire Meshfinds applications for coal industry, mining industry, furniture use, farm & agricultural use, building & construction, architectural applications, artistic applications, and many more.These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards.Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.

Superior Material Properties

Our wire mesh utilizes non-alloy, low carbon steel, chosen for its balance of strength and workability. With precisely controlled tensile strength and elongation, as well as a protective surface coating for corrosion resistance, it delivers reliable performance in demanding environments. Each mesh is crafted under strict quality standards and is available with customizable dimensions and roll lengths, ensuring suitability for specialized project needs.

Diverse Applications & Performance

Ideal for construction, fencing, filtration, and architectural purposes, the mesh excels due to its structural integrity and targeted surface treatments. Offered in welded or woven styles, with variable aperture sizes and wire gauges, it supports a wide spectrum of functions from robust perimeter security to fine filtration solutions.

Flexible Packaging & Supply

To accommodate logistics, our mesh is supplied in rolls or bundles, with a minimum order quantity of 100 square meters. As an Indian exporter, manufacturer, supplier, and trader, we serve global and domestic markets, offering both standard and fully customized mesh solutions for various industry sectors.

FAQs of Low Carbon Steel Wire Mesh:

Q: How is the low carbon steel wire mesh constructed and what standards does it comply with?

A: The mesh is crafted using premium low carbon steel wires and produced in either welded or woven styles. It is available in various wire diameters and mesh apertures, and conforms to international ASTM, DIN, and ISO standards, ensuring consistent quality and mechanical performance.Q: What protective measures enhance this wire meshs corrosion resistance?

A: Each wire mesh comes coated with a protective layer that shields the steel from corrosion, making it suitable for both indoor and outdoor applications. This treatment prolongs product life, especially in challenging environments.Q: When should I choose welded vs. woven mesh style?

A: Welded mesh is recommended for applications requiring high structural integritysuch as construction reinforcement and fencingwhile woven mesh is ideal for filtration and architectural elements where flexibility and precision grid spacing are important.Q: Where can this wire mesh be installed or utilized?

A: It is designed for a diverse range of settings, including construction sites, industrial plants, fencing perimeters, filtration systems, and architectural installations. Its adaptability in dimensions and shapes allows seamless integration into various projects.Q: What is the process for customizing dimensions and ordering?

A: Simply provide your required roll width, mesh length, aperture size, and wire gauge. Orders start with a minimum of 100 square meters, and the mesh can be packed in rolls or bundles according to your logistical needs. We offer global shipping from India.Q: How does the meshs temperature resistance benefit industrial projects?

A: Withstanding temperatures up to 400C, the mesh is suitable for environments with elevated thermal conditions, such as industrial filtration or kiln linings, while maintaining structural stability and safety.Q: What are the main advantages of using low carbon steel wire mesh with a protective coating?

A: It delivers an optimal mix of tensile strength, corrosion resistance, and long-term durability. The coated surface not only extends service life but also reduces maintenance, making it a cost-effective choice across various industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Steel Wire Mesh Category

High Carbon Steel Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, High Carbon Steel

Color : Silver Grey

Alloy : High Carbon

Surface Treatment : Galvanized

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry