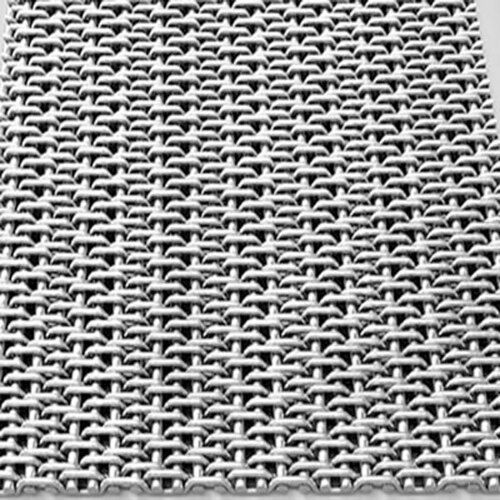

Monel 400 Twill Dutch Weave Wire Mesh

Price 50 INR/ Unit

Monel 400 Twill Dutch Weave Wire Mesh Specification

- Surface Treatment

- Coated

- Wire Gauge

- 36 Gauge

- Hole Shape

- Rectangular

- Aperture

- 0.034 mm

- Length

- 30 Meter (m)

- Product Type

- Wire Mesh

- Mesh Type

- Twill Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Monel

- Alloy

- Monel 400

- Application

- Other

- Dimensions

- 1.2 m x 30 m

- Wire Diameter

- 0.03 mm

- Weight

- ~35 kg/roll

- Color

- Gray

Monel 400 Twill Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Monel 400 Twill Dutch Weave Wire Mesh

Monel 400 is a combination of nickel and copper making it one of the most multipurpose and widely used nickel alloys. Monel comprises more than 60% and is a versatile alloy, as a copper-nickel alloy exhibits high strength and excellent corrosion resistance in a wide range of media, including sea water and in acidic and alkaline environments.Monel 400 is drawn to specific diameter wires and woven to certain specifications.The Monel 400 Twill Dutch weave has a high filtering level and high pressure load resistance.The Monel 400 Twill Dutch Weave Wire Mesh can be Woven and Welded. We offer an exclusive range ofMonel 400 Twill Dutch Weave Wire Meshat unmatched quality and market leading prices.

Exceptional Corrosion Resistance

Monel 400 Wire Mesh demonstrates excellent resistance to acids, alkalis, and seawater, making it ideal for marine and chemical filtration tasks. The alloy composition ensures prolonged structural integrity even under harsh conditions, minimizing maintenance requirements.

Precision Filtration with Twill Dutch Weave

The Twill Dutch Weave style delivers ultra-fine filtration with a nominal aperture of 0.034 mm. This advanced weaving technique increases durability while offering precise particle retention for specialized separation and filtration applications in chemical and pharmaceutical industries.

Engineered for High Temperature and Strength

Designed to withstand continuous temperatures up to 480C and possessing a tensile strength of 550 MPa, Monel 400 mesh remains robust under thermal and mechanical stress. Its capacity to retain properties at elevated temperatures suits demanding industrial environments.

FAQs of Monel 400 Twill Dutch Weave Wire Mesh:

Q: How does the Twill Dutch Weave contribute to filtration efficiency?

A: The Twill Dutch Weave configuration provides tighter weaving and finer openings, enhancing the meshs ability to capture microscopic particles. This results in improved filtration performance in industries requiring precision, such as chemical processing and pharmaceuticals.Q: What are the primary applications of Monel 400 Twill Dutch Weave Wire Mesh?

A: This wire mesh excels in filtration, separation, and screening tasks in marine, chemical, and pharmaceutical industries due to its high corrosion resistance and fine aperture. It is frequently used in the production of filter elements and sieves where robust and precise filtration is crucial.Q: When is this wire mesh preferred over stainless steel alternatives?

A: Monel 400 mesh is preferred in environments featuring strong acids, alkalis, or saline solutions, where stainless steel may degrade. Its superior corrosion resistance ensures reliability and longevity in harsh chemical and marine conditions.Q: Where can Monel 400 Twill Dutch Weave Wire Mesh be sourced in India?

A: Monel 400 Twill Dutch Weave Wire Mesh is available through exporters, manufacturers, suppliers, and traders across India. Companies specializing in industrial filtration materials typically stock this product adhering to ASTM standards.Q: What is the process behind manufacturing Monel 400 Twill Dutch Weave Wire Mesh?

A: The mesh is fabricated using precision wire drawing and weaving machinery, achieving a consistent wire diameter of 0.03 mm and an accurate opening size of 0.034 mm. The process finishes with a specialized coating for enhanced durability and corrosion resistance.Q: How can users benefit from the high flexibility of the mesh?

A: The meshs flexibility allows for easy fabrication into different shapes and filter cartridges without compromising strength or integrity. This adaptability is invaluable in installations with complex requirements or tight spaces.Q: What maintenance protocols should be followed to maximize mesh lifespan?

A: Routine inspection for physical damage or coating wear is recommended. Cleaning with non-abrasive solutions will help retain its structural and filtration properties, particularly in aggressive environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Twill Dutch Weave Wire Mesh Category

Titanium Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

Mesh Style : Plain Mesh

Steel Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Gray

Surface Treatment : Coated

Product Type : Wire Mesh

Mesh Style : Plain Mesh

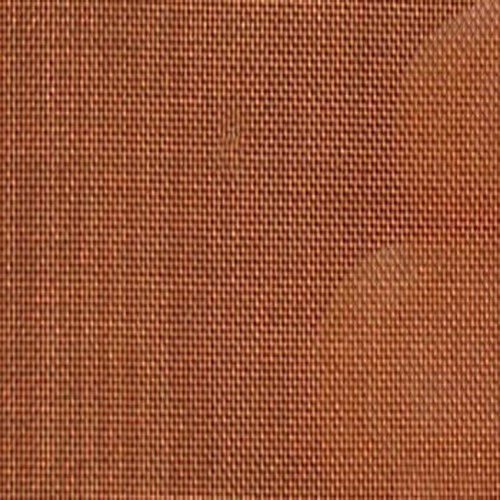

Copper Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Copper

Surface Treatment : Coated

Product Type : Wire Mesh

Mesh Style : Other , Twill Dutch Weave

Bronze Twill Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Bronze

Surface Treatment : Powder Coating, Galvanized, Painted, Welding, Polished

Product Type : Wire Mesh

Mesh Style : Plain Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry