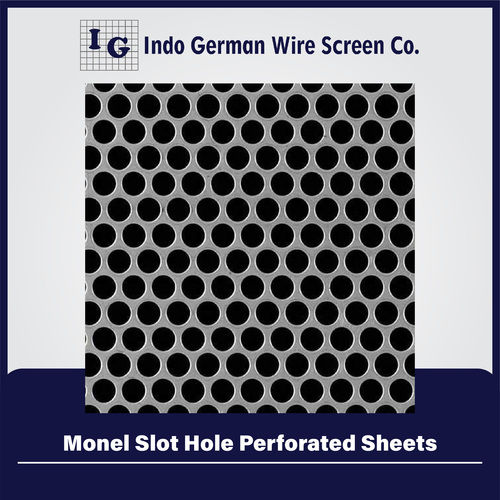

Monel Slot Hole Perforated Sheets

Price 50 INR/ Unit

Monel Slot Hole Perforated Sheets Specification

- Surface Treatment

- Polished, Unpolished, Custom Surface Finish Available

- Temper

- Annealed, As Rolled

- Process

- Cold Rolled, Hot Rolled

- Standard

- ASTM B127, ASTM B165

- Shape

- Rectangular, Square, Custom Shapes

- Material

- Monel Alloy (typically Monel 400 or Monel K500)

- Type

- Slot Hole Perforated Sheet

- Technique

- Perforation with Precision Slot Punching

- Thickness

- 0.5 mm to 12 mm (Customizable)

- Application

- Chemical Processing, Marine Applications, Oil & Gas, Power Generation

- Feature

- Corrosion Resistance, Sturdy Construction, Fine Finish

- Edge Type

- Plain, Sheared, or Custom Edges

- MOQ (Minimum Order Quantity)

- As per customer requirement

- Sheet Length

- 1000 mm to 6000 mm

- Density

- 8.8 g/cm³

- Yield Strength

- 240 MPa (Monel 400)

- Open Area Percentage

- 10% to 60% (Customizable)

- Maximum Operating Temperature

- Up to 600°C

- Tensile Strength

- 485 MPa (Monel 400)

- Packing

- Wooden Box, Carton, or as per requirement

- Sheet Width

- 500 mm to 1500 mm

- Slot Hole Size

- 0.5 mm to 30 mm length (custom size available)

About Monel Slot Hole Perforated Sheets

Monel 400is a combination of Nickel and Copper making it one of the most multipurpose and widely used nickel alloys. Monel comprises more than 60% andis a versatile alloy, as a copper-nickel alloy exhibits high strength and excellent corrosion resistance in a wide range of media, including sea water and in acidic and alkaline environments.Depending on applications and requirements, patterns of perforated sheets can be round-staggered, round-straight, slotted holes. Although the process of perforating improves the exterior of metals, it has other useful special uses like protection and noise suppression.compared to similar perforated sheet with other hole patterns, these are a perfect solution to filtrate and sieve liquids and solids, such as water, grain, wine, and seeds, etc.Exceptional Customizability for Varied Applications

Customers can specify everything from slot hole size (0.5 mm to 30 mm), thickness (0.5 mm to 12 mm), to edge type and open area percentage, ensuring each sheet meets precise operational needs. With a choice of surface finishes and shapes, our Monel perforated sheets adapt seamlessly to specialized industry requirements.

Superior Durability and Corrosion Resistance

Monel alloysrenowned for their resistance to acids and corrosive environmentsmake these perforated sheets ideal for harsh marine, chemical, and oil & gas settings. Their robust construction, high strength, and superior finish guarantee lasting performance even under demanding conditions.

Engineered to Global Quality Standards

State-of-the-art manufacturing processes, including cold and hot rolling and precision perforation, ensure each sheet meets stringent ASTM B127 and ASTM B165 standards. We offer a range of customized options, from edge types to packing, providing dependable solutions for global exporters and demanding domestic clients alike.

FAQs of Monel Slot Hole Perforated Sheets:

Q: How is the slot hole size determined for Monel perforated sheets?

A: Slot hole sizes are customizable, ranging from 0.5 mm to 30 mm in length, allowing clients to specify dimensions best suited for their applications. Our precision slot punching technique enables highly accurate perforation tailored to your requirements.Q: What are the benefits of using Monel alloy in perforated sheets?

A: Monel alloys, such as Monel 400 and K500, provide outstanding corrosion resistance, high tensile and yield strength, and durability in harsh environments. This makes them suitable for sectors like marine engineering, chemical processing, and power generation.Q: When should Monel Slot Hole Perforated Sheets be used?

A: These sheets are ideal when applications demand high corrosion resistance, reliable structural strength, and durability at elevated temperatures, such as in marine, oil & gas, chemical, and power generation industries.Q: What surface finishes and edge types are available?

A: We offer polished, unpolished, and custom surface finishes. Edge types include plain, sheared, or customized according to project specifications, ensuring optimal integration into your application.Q: How are the sheets manufactured and what standards do they follow?

A: The sheets are produced using cold or hot rolling followed by precision slot punching, in compliance with ASTM B127 and ASTM B165 standards to ensure outstanding quality and consistent performance.Q: Where can Monel Slot Hole Perforated Sheets be sourced from?

A: We supply these sheets globally as a manufacturer, exporter, supplier, and trader based in India. Customization and international shipping are readily available to cater to diverse locations.Q: What is the minimum order quantity and how are the sheets packed?

A: The minimum order quantity is flexible, based on customer requirements. Packaging options include wooden boxes, cartons, or custom packaging to ensure safe and secure transport.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Slot Hole Perforated Sheets Category

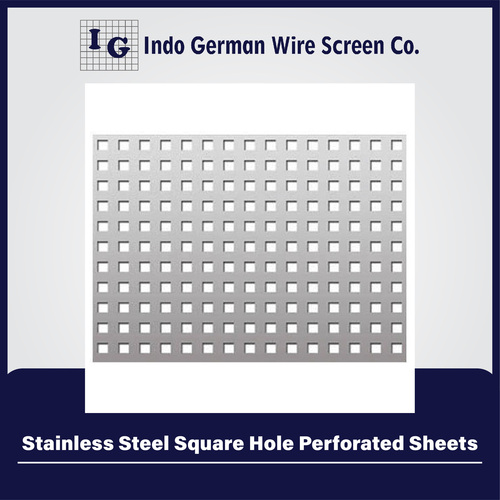

Stainless Steel Square Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Other , Polished, Matte, or Noncoated

Type : Square Hole Perforated Sheet

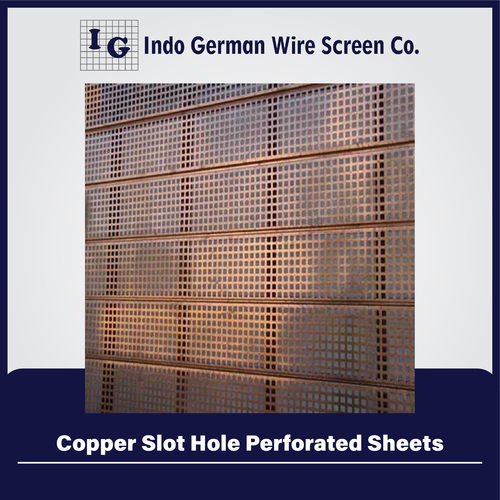

Copper Slot Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , Copper

Surface Treatment : Polishing

Type : Perforated Sheets

Usage : Industrial

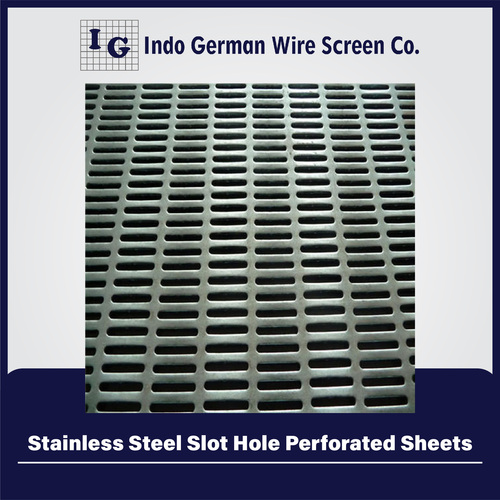

Stainless Steel Slot Hole Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Surface Treatment : Polishing

Type : Perforated Sheets

Usage : Industrial

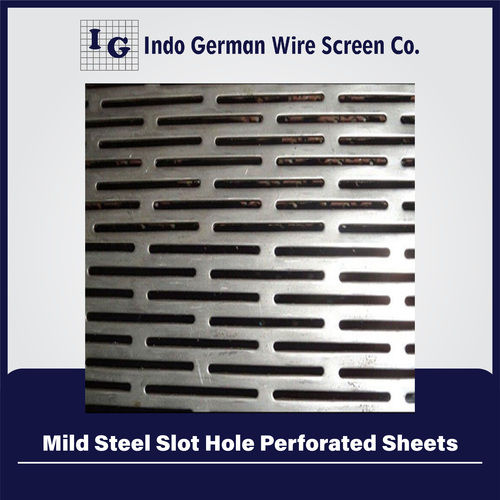

Mild Steel Slot Hole Perforated Sheets

Price 250 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , Mild Steel

Surface Treatment : Polishing

Type : Perforated Sheets

Usage : Industrial

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry