Multilayer Circular Screen

Multilayer Circular Screen Specification

- Length

- Custom lengths available

- Wire Gauge

- Customized as per requirement

- Aperture

- 0.5 mm to 10 mm

- Hole Shape

- Round

- Surface Treatment

- Polished

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Multilayer Circular

- Material

- Stainless Steel

- Alloy

- SS304/SS316/SS316L

- Application

- Screening, Filtration, Industrial Separation, Chemical, Food Processing, Pharmaceutical

- Dimensions

- Custom sizes as per client specifications

- Wire Diameter

- 0.15 mm to 2.0 mm

- Weight

- Based on size and layer, typically 2-15 kg each

- Color

- Silver

- Operating Temperature

- Up to 800°C

- Tolerance

- ±0.02 mm

- Standards

- ASTM, DIN, ISO

- Corrosion Resistance

- Excellent

- Edge Type

- Plain or Bordered

- Number of Layers

- 2 to 5 layers

- Open Area

- Dependent on mesh and aperture, customized

- Packing Type

- Wooden box or as per requirement

Multilayer Circular Screen Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Multilayer Circular Screen

Supported by the highly talented professionals and modern manufacturing unit, we have become a highly reliable manufacturer, exporter, trader, importer and supplier of premium quality of Multilayer Circular Screen that is extensively used in various industries. The offered screen is manufactured by the using of premium quality raw materials and highly advances machinery under the supervision of our experienced professionals in accordance with set market standards. Furthermore, we provide the offered Multilayer Circular Screen in required dimensions at affordable prices.

Features:

- Perfect strength

- Lightweight

- Optimum finish

- Resistance from rust

Product details

| Feeding size | 400 mm |

| Material Grade | 301, 302, 302B, 303, 304, 304L, 305, 308, 309, 309S, 310, 310S, 314, 316, 317, 321, 347, 410, 430 |

| Type | Woven |

| Material | Stainless Steel |

| Hole Shape | Square, Circular |

Precision Built for Industrial Excellence

Designed with meticulous attention to detail, these multilayer circular screens incorporate steel wire mesh with customizable wire gauge and mesh type, accommodating a range of applications from chemical separation to food processing. Their ability to withstand high temperatures and corrosive environments sets them apart in reliability and longevity.

Flexible Customization for Unique Needs

Available with a variety of edge types and hole shapesincluding round and other customized aperturesthese screens are manufactured in any length or dimension required. With open area adjustable according to mesh and aperture choice, users can tailor their screens to maximize efficiency for their specific screening or filtration process.

FAQs of Multilayer Circular Screen:

Q: How are the Multilayer Circular Screens customized for different applications?

A: Customization is achieved by selecting from 2 to 5 layers, various mesh styles, wire gauges, apertures, edge types (plain or bordered), and dimensions. This flexibility ensures that the screens meet unique requirements for screening, filtration, or industrial separation in sectors like chemical, food processing, or pharmaceutical industries.Q: What materials are used in the manufacture of these screens?

A: The screens are manufactured from high-grade stainless steel alloys, specifically SS304, SS316, and SS316L, which offer excellent corrosion resistance, durability, and safe operation at temperatures up to 800C.Q: When should I use a multilayer circular screen instead of a single layer?

A: Multilayer screens are recommended when finer or graduated filtration is required, or when handling processes with varying particle sizes. Multiple layers increase efficiency and can improve separation accuracy in screening and filtration processes.Q: Where are these screens typically installed or utilized?

A: These circular screens are widely utilized in industrial environments such as chemical processing plants, food production facilities, pharmaceutical manufacturing, and applications involving filtration, screening, and separation operations.Q: What is the process for obtaining a customized screen?

A: To obtain a customized screen, clients provide specifications regarding layer count, mesh type, wire gauge, aperture size and shape, edge preference, and dimensions. The manufacturer then produces the screen to these exact standards and packs it securely, typically in a wooden box or as requested.Q: How do these screens benefit industrial operations?

A: Their robust construction, excellent corrosion and heat resistance, and customizable features enhance operational efficiency, reduce downtime, and ensure long-lasting and reliable filtering or separation performance throughout demanding processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Screen in Circular/ Square PC Category

Multilayer Cylindrical Screens

Minimum Order Quantity : 1 Piece

Color : Silver

Material : Stainless Steel

Product Type : Wire Mesh

Surface Treatment : Polished

Filter Disc

Price Range 350.00 - 700.00 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Black

Material : Steel

Product Type : Wire Mesh

Surface Treatment : Polished

Circular Screens

Price Range 20.00 - 200.00 INR / Piece

Minimum Order Quantity : 100 Pieces

Color : Silver

Material : Aluminum

Product Type : Wire Mesh

Surface Treatment : Polished

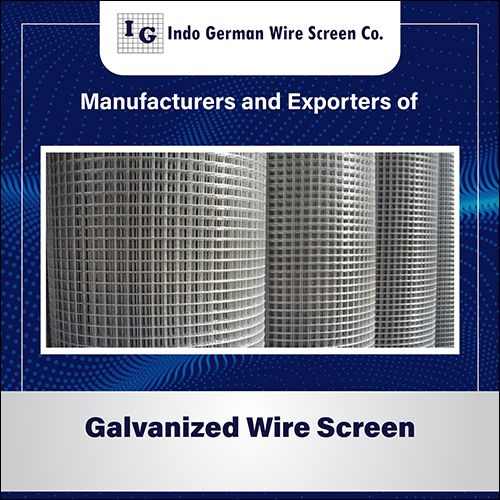

Galvanized Wire Screen

Color : Sliver

Material : Steel

Product Type : Wire Mesh

Surface Treatment : Polished

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry