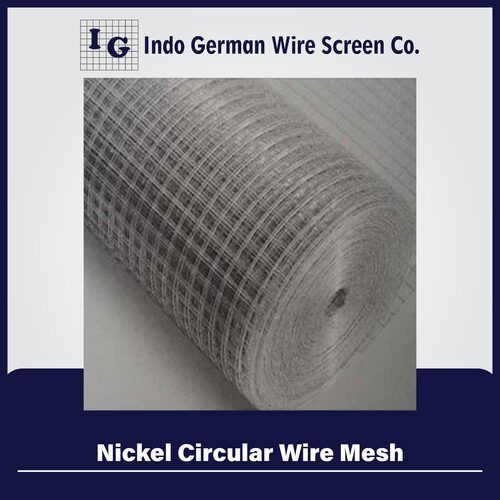

Nickel Circular Wire Mesh

Price 50 INR/ Unit

Nickel Circular Wire Mesh Specification

- Wire Gauge

- Customizable as per requirement

- Aperture

- Varying sizes (typically 0.2 mm to 5 mm)

- Hole Shape

- Round

- Length

- Standard and custom lengths available

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Woven / Crimped

- Mesh Style

- Plain Mesh

- Material

- Other

- Alloy

- Nickel 201; other nickel alloys on request

- Application

- Filtration, Separators, Chemical Processing, Battery Electrode, Catalysis

- Dimensions

- Available in circular discs, diameter as per requirement

- Wire Diameter

- Standard range 0.2 mm to 2 mm

- Weight

- Depends on mesh and dimensions

- Color

- Silver

Nickel Circular Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Nickel Circular Wire Mesh

Nickel is a silvery-white hard metal whose strength, ductility and resistance to heat and corrosion make it exceptionally useful for the manufacturing of a wide range of materials from wires to coins to military equipment. Nickel is woven using high purity nickel wire and is mostly favoured in corrosive environments such as filtration of liquids, gas, etc.Circular Wire cloth plain weaveis the most frequently used weave in which each warp wire crosses interchangeably above and below each weft wire. Warp wires and weft wires usually have the same diameter.

Exceptional Corrosion Resistance

Nickel Circular Wire Mesh excels in harsh environments, including acidic and alkaline settings, due to its outstanding corrosion resistance. The high-purity nickel alloy construction ensures long-lasting performance and reliability for critical applications such as chemical processing and filtration. This mesh withstands aggressive agents where conventional materials fail, minimizing maintenance and maximizing operational safety.

Versatile Application & Customization

Offered in diverse mesh counts, wire diameters, and disc sizes, this mesh is engineered for flexibility. Whether you need woven or crimped types, standard or custom dimensions, or unique shapes such as round or other apertures, each specification is designed to meet the precise requirements of sieving, screening, or reinforcement tasks. Packaging optionsrolls, sheets, or cut circlesfurther enhance practicality.

Superior Conductivity and Strength

Nickel mesh delivers excellent electrical conductivity, making it ideal for battery electrodes and industrial catalysis. The strong tensile strength, adjusted as per wire gauge, provides robust structural integrity in demanding scenarios. High operating temperatures up to 600C expand its suitability for applications that involve heat or thermal cycling, ensuring safe and reliable performance over time.

FAQs of Nickel Circular Wire Mesh:

Q: How can the wire gauge and mesh count be customized for Nickel Circular Wire Mesh?

A: Wire gauge and mesh count are both customizable according to your requirements. Mesh count ranges from 10 to 200 mesh per inch, and wire diameter is available from 0.2 mm to 2 mm. Specify your desired configuration to suit your application.Q: What applications benefit most from using Nickel Circular Wire Mesh?

A: Nickel Circular Wire Mesh is well-suited for filtration, chemical processing, battery electrodes, catalysis, sieving, and screening, especially where high corrosion resistance and conductivity are vital.Q: When is Nickel Circular Wire Mesh preferred over other metal meshes?

A: This mesh is preferred when exposure to acidic or alkaline environments, high temperatures (up to 600C), or the need for high electrical conductivity are critical factors in your process or equipment.Q: Where can Nickel Circular Wire Mesh be supplied, and what are the shape options?

A: It is supplied globally from India by exporters, manufacturers, suppliers, and traders. Standard shapes include circular discs, but custom shapes and sizes are available upon request.Q: What is the process for ordering custom sizes or shapes?

A: To order a custom size or shape, provide details such as mesh count, wire gauge, diameter, aperture size, and required quantity. Manufacturers will tailor the mesh to fit precise requirements, ensuring optimal performance for specific uses.Q: How does the surface treatment and coating benefit the mesh?

A: The coated surface treatment enhances the meshs corrosion resistance and lifespan, offering additional durability in aggressive operational environments.Q: What packaging options are available for Nickel Circular Wire Mesh?

A: Depending on your needs, the mesh can be packaged as rolls, sheets, or cut circles/discs, making handling and installation convenient for various industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Circular Wire Mesh Category

Titanium Circular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Gray

Surface Treatment : Coated

Application : Other

Product Type : Wire Mesh

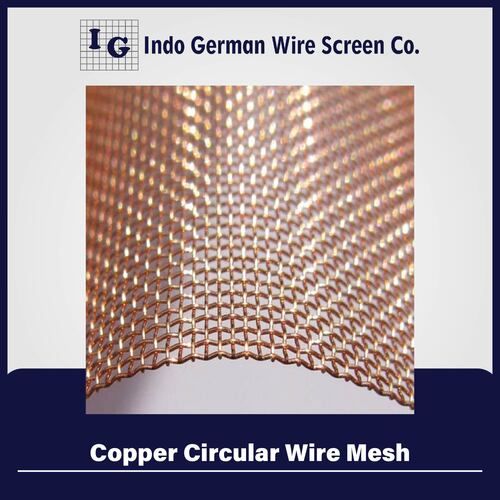

Copper Circular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Copper

Surface Treatment : Coated

Application : Other

Product Type : Wire Mesh

Monel 400 Circular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Application : Other

Product Type : Wire Mesh

Bronze Circular Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Surface Treatment : Coated

Application : Other

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry