Nylon Wire Mesh

Price 12 INR/ Square Foot

Nylon Wire Mesh Specification

- Length

- Customized as per order

- Surface Treatment

- Painted

- Wire Gauge

- Standard (varies per requirement)

- Hole Shape

- Square

- Aperture

- Available in various sizes (customizable)

- Product Type

- Wire Mesh

- Mesh Type

- Iron Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Other

- Alloy

- Not applicable (synthetic fiber)

- Application

- Filtration, Sieving, Industrial Usage, Decorative

- Dimensions

- Standard and custom sizes available

- Wire Diameter

- Typically ranges from 0.1 mm to 1 mm

- Weight

- Lightweight, varies by mesh count and dimensions

- Color

- White

- Packing Type

- Rolls or as per customer specifications

- Open Area

- 6080% (varies by mesh size)

- Weave Type

- Plain weave

- Temperature Resistance

- Up to 120C

- Feature

- Corrosion resistant, Durable, Flexible, Easy to clean

- Chemical Resistance

- Good against acids & alkalis

Nylon Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Nylon Wire Mesh

Nylon Wire Mesh offered by us is widely utilized for printing, screening, filtering, and surgical purposes. It is said to be light in weight and assures a bright & clear printed surface. This mesh can also be availed with an adhesive backing layer on request. It is completely non-toxic in nature and can easily be recycled. This wire mesh is highly resistant to most chemicals and shows good UV stability. It is available in different colors and mesh sizes as demanded by our trusted customers. Nylon Wire Mesh provided by us can easily be printed with the help of latest digital printers without causing much wear to printhead rollers.

Special Features :

- It is used as suitable filtration element for filter cloth and disc.

- Apart from nylon thread, standard grade PP and polyester have been used for its fabrication.

- Available in different micron range of mesh, width and thickness based options

- Excellent elongation rate, high temperature enduring capacity and uniform filament structure

Product details

|

Filter Rating |

27%-80% nylon filter mesh |

|

Usage |

Liquid Filter |

|

Material |

Nylon |

|

Hole Shape |

Square |

Robust Construction and Adaptability

This nylon wire mesh stands out for its plain weave structure, lightweight profile, and versatility. Engineers can select from a wide range of aperture sizes and wire gauges based on filtration needs or decorative preferences. Its synthetic fiber build keeps it rust-free and effective in diverse environments.

Superior Chemical and Temperature Resistance

Engineered to withstand temperatures up to 120C and resist degradation from most acids and alkalis, this mesh is well-suited for industrial settings. Its painted surface enhances durability, while easy cleaning procedures ensure maintenance is straightforward.

Flexible Sizing for Every Application

We accommodate customer-specific demands by offering both standard and tailored dimensions. From sieving granular materials to enhancing architectural aesthetics, the meshs customization options ensure it fits seamlessly into a variety of projects.

FAQs of Nylon Wire Mesh:

Q: How is the nylon wire mesh typically used across industries?

A: Nylon wire mesh is widely used in filtration, sieving, and industrial applications due to its high open area, durability, and resistance to corrosion. Its also employed in decorative and architectural projects where a lightweight yet robust mesh is needed.Q: What is the process for ordering customized sizes and specifications?

A: Customers can specify their requirements for wire diameter, aperture, length, color, and packing type. Orders can be tailored to standard or custom dimensions, and our team will guide you through the process to ensure the correct mesh for your application.Q: When should I choose a plain weave nylon wire mesh over other options?

A: Plain weave nylon wire mesh is ideal when you need maximum flexibility, chemical resistance, and a consistent open area. Its structure is suitable for precise sieving and filtration, especially where corrosion resistance and easy cleaning are priorities.Q: Where can the mesh be installed or applied?

A: The mesh can be installed in various settings, including industrial filtration equipment, laboratory sieves, architectural facades, and decorative panels. Its adaptability ensures it meets the demands of both functional and aesthetic applications.Q: What are the main benefits of using a nylon wire mesh with painted surface treatment?

A: A painted surface further enhances the meshs resistance to environmental factors, increases longevity, and provides an easy-to-clean finish. It also allows for color customization to match specific project requirements.Q: Is the mesh safe to use with acids and alkalis?

A: Yes, the nylon mesh offers good chemical resistance, making it appropriate for environments involving exposure to acids and alkalis. However, verifying compatibility with your exact chemicals is advisable for optimum performance.Q: How should the mesh be maintained to ensure longevity?

A: Nylon mesh is easy to maintain; regular cleaning with water or mild detergent will suffice. Avoid using harsh cleaning agents not compatible with nylon fibers to preserve its durability and function over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Black Wire Cloth

Price 14 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Polished

Product Type : Wire Cloth

Mesh Type : Other

Color : Black

Welded Mesh Panels

Price 120 INR

Minimum Order Quantity : 10 Square Meters

Surface Treatment : Other, Galvanized / PVC Coated / Stainless Steel

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Color : Sliver

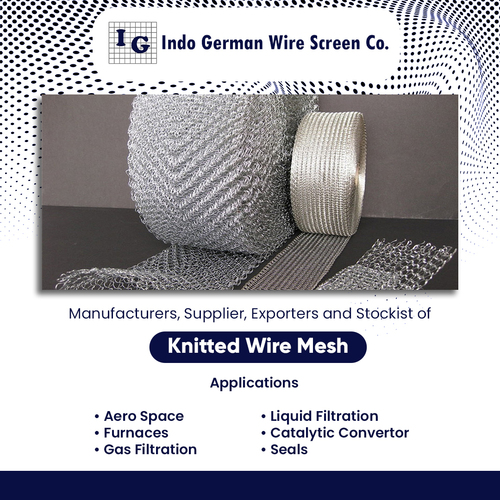

Knitted Wire Mesh

Minimum Order Quantity : 10 Kilograms

Surface Treatment : Polished

Product Type : Wire Mesh

Mesh Type : Other , knitted wire net

Color : Silver

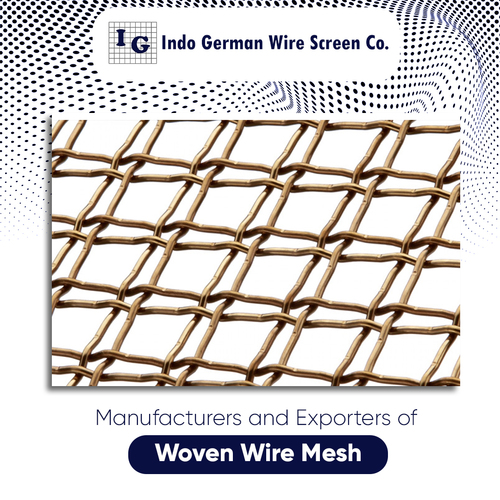

Woven Wire Mesh

Price 50 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Surface Treatment : Polished

Product Type : Wire Mesh

Mesh Type : Aluminum Wire Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry