Sifter Sieves For Granules

Price 1000 INR/ Foot

Sifter Sieves For Granules Specification

- Shape

- Round

- Surface Treatment

- Polished

- Process

- Laser cutting/ Punching/ Welding

- Standard

- ASTM/IS or as per client specification

- Temper

- Annealed

- Usage

- industrial

- Material

- Stainless Steel

- Type

- Sifter Sieves

- Technique

- Perforated/ Woven Mesh fabrication

- Product Type

- Sifter Sieves

- Color

- Steel

- Thickness

- Customizable (commonly 0.5mm to 1.0mm)

- Application

- Sieving and grading of granules in industrial processes

- Feature

- High durability, Corrosion resistant, Easy to clean

- Diameter

- Available from 8 inches to 48 inches or as specified

- Mesh Size

- Custom sizes available (from 4 mesh onwards)

- Cleaning Method

- Manual or machine washable

- End Connection

- Plain/ With gasket/ With ring

- Tolerance

- Strict dimensional tolerance maintained (+/- 0.1mm)

- Edge Finish

- Crimped, Bended, Welded or as required

- Packing Type

- Corrugated box/ Wooden crate

Sifter Sieves For Granules Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Paypal, Cash Advance (CA), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Sifter Sieves For Granules

We are one of the renowned and trusted manufacturers of Sifter sieves for Granules. We offer our clients with a qualitative assortment of Sifter Sieves. Our range also includes cross welded at the bottom of the ring for additional service support. These Sifter Sieves are offered in both standard and customized designed and are available in Plain weave, Dutch Weave, Twill weave with customised specification of mesh size and wire diameter.

Product details

|

Country of Origin |

Made in India |

|

Material |

SS |

|

Customisation |

Customised |

|

Shape |

Round |

|

Model Name/Number |

Sifter Sieves For Granules |

Custom Mesh Sizes and Diameters

Select from a wide array of mesh sizes, starting at 4 mesh and upwards, and diameters from 8 inches up to 48 inches or more. This flexibility allows you to tailor the sieves precisely to your industrial application, ensuring optimal grading and separation of granules for your process requirements.

Durable Stainless Steel Construction

Manufactured using premium stainless steel, our sifter sieves offer excellent durability and strong resistance to corrosion. With sophisticated fabrication techniques such as perforated or woven mesh, and polished or annealed surfaces, these sieves are built to deliver reliable performance in demanding industrial environments.

Easy Maintenance and High Precision

Whether cleaned manually or with machines, these sieves are designed for hassle-free maintenance. Strict dimensional tolerances guarantee consistent results, while various edge finishes and end connections provide secure fitting and adaptability within your existing sieving setups.

FAQs of Sifter Sieves For Granules:

Q: How do I select the appropriate mesh size and diameter for my sifter sieve?

A: Mesh size and diameter should be based on your specific granule size and throughput requirements. Mesh sizes start from 4 mesh, and diameters are available from 8 to 48 inches or as needed. If you have unique requirements, custom sizes can be specified to suit your industrial process.Q: What materials and edge finishes are offered for these sifter sieves?

A: Our sifter sieves are made from stainless steel for superior durability and corrosion resistance. You can choose edge finishes like crimped, bended, welded, or others as required to match your applications installation and handling preferences.Q: When should I opt for a particular end connection, such as with gasket or with ring?

A: The choice of end connectionplain, with gasket, or with ringdepends on your systems sealing and fitting requirements. End connections with gaskets or rings are recommended for improved sealing and stability in high precision or sensitive environments.Q: Where are these sifter sieves commonly used?

A: These sieves are primarily used in industrial settings, such as chemical, pharmaceutical, food, or mineral processing plants, for sieving and grading granules as part of bulk material handling operations.Q: What is the process for manufacturing the sifter sieves?

A: Sifter sieves are fabricated using techniques like perforated or woven mesh, laser cutting, punching, and welding. They are made to ASTM, IS, or custom specifications, with options for polished and annealed surfaces to meet client needs.Q: How can these sieves be cleaned and maintained?

A: Cleaning can be performed manually or using industrial washing machines. Their stainless steel construction and polished surfaces facilitate easy cleaning and help prevent residue buildup, ensuring hygienic and efficient operation.Q: What are the main benefits of using stainless steel sifter sieves in industrial applications?

A: Key benefits include high durability, excellent corrosion resistance, easy cleaning, customizable thickness, and precise dimensional tolerances for consistent grading of granules. Their robust design ensures longevity and reliable performance in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

Sifter Sieves For Chemical Industry

Price 1000 INR / Foot

Minimum Order Quantity : 10 Feet, ,

Usage : industrial

Material : Stainless Steel

Product Type : Sifter Sieves For Chemical Industry

Shape : Round

Sieve for Conical Mills

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Usage : industrial

Material : Stainless Steel

Product Type : Sieve for Conical Mills

Shape : Round

Perforated Coils

Minimum Order Quantity : 10 Square Foots

Usage : industrial

Material : Stainless Steel Wire

Product Type : Perforated Coils

Shape : Round

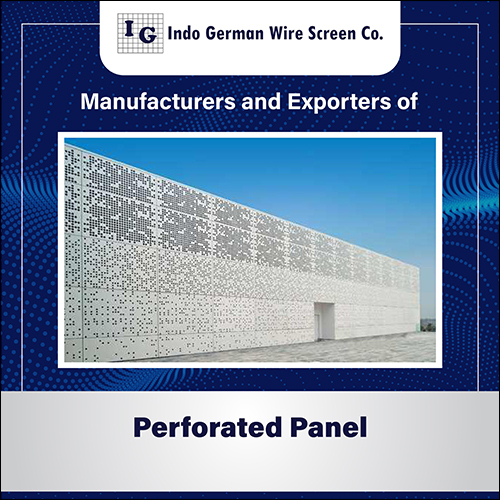

Perforated Panel

Price 85 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Usage : industrial

Material : Stainless Steel Wire

Product Type : Perforated Panel

Shape : Circular

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry