Sifter Sieves For Pharma Industry

Price 1000 INR/ Foot

Sifter Sieves For Pharma Industry Specification

- Surface Treatment

- Polished

- Standard

- GMP compliant

- Temper

- Hard

- Shape

- Round

- Process

- Laser cutting, edge finishing

- Usage

- industrial

- Material

- Stainless Steel

- Type

- Sifter Sieves

- Technique

- Perforated and woven mesh technology

- Product Type

- Sifter Sieves For Pharma Industry

- Color

- Steel

- Thickness

- 0.5 mm to 1.5 mm

- Application

- Pharma industry sieving and sifting operations

- Feature

- Corrosion resistant, High efficiency sieving, Hygienic construction

- Screen Type

- Single or multi-layer

- Diameter

- Custom sizes available (standard: 12, 20, 30, 36, 48)

- Compatibility

- Fits various pharmaceutical sifter machines

- Packing

- Individually packed in polybags or wooden cases

- Mesh Size

- From 10 microns to 5000 microns

- Cleaning

- Compatible with CIP/SIP processes

- Edge Type

- Silicon rubber or SS bound edge

Sifter Sieves For Pharma Industry Trade Information

- Minimum Order Quantity

- 10 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Paypal, Letter of Credit (L/C), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Domestic Market

- All India

About Sifter Sieves For Pharma Industry

We are one of the renowned and trusted manufacturers of Sifter sieves for Pharma Industry. We offer our clients with a qualitative assortment of Sifter Sieves. Our range also includes cross welded at the bottom of the ring for additional service support. These Sifter Sieves are offered in both standard and customized designed and are available in Plain weave, Dutch Weave, Twill weave with customised specification of mesh size and wire diameter.

Product details

|

Country of Origin |

Made in India |

|

Material |

SS |

|

Customisation |

Customised |

|

Shape |

Round |

|

Model Name/Number |

Sifter Sieves For Pharma Industry |

Custom Sifter Sieves for Every Pharmaceutical Need

Our sifter sieves are tailored for the pharmaceutical industrys stringent requirements. Available in mesh sizes from 10 to 5000 microns and various diameters, they ensure accurate and efficient sieving. The hygienic, corrosion-resistant stainless steel construction meets all GMP standards, supporting safe and reliable production processes.

Advanced Manufacturing and Edge Options

Produced with both perforated and woven mesh technology, our sieves undergo precise laser cutting and edge finishing to deliver consistent results. Customers can select either silicon rubber or SS bound edges for added compatibility and durability, benefitting from high-quality craftsmanship every step of the way.

Effortless Integration and Maintenance

These sieves fit seamlessly with a range of pharmaceutical sifter machines and are designed for easy cleaning, compatible with CIP (Clean-in-Place) and SIP (Sterilize-in-Place) systems. Each unit is securely packed in polybags or wooden cases, ensuring optimal delivery condition and straightforward maintenance.

FAQs of Sifter Sieves For Pharma Industry:

Q: How are mesh sizes selected for specific pharmaceutical sifting requirements?

A: Mesh sizes for sifter sieves range from 10 to 5000 microns. Selection depends on the particle size that needs to be separated during pharma processes. Finer meshes are suitable for dust-like powders, while coarser meshes accommodate larger granules. Our expert team can guide you to the optimal mesh for your application.Q: What cleaning processes are compatible with these sifter sieves?

A: The sieves support both CIP (Clean-in-Place) and SIP (Sterilize-in-Place) protocols, crucial for maintaining hygiene in pharmaceutical production. Their stainless steel construction withstands repeated washing and sterilization, contributing to compliance with industry standards.Q: When should multi-layer sifter sieves be chosen over single-layer alternatives?

A: Multi-layer sifter sieves are recommended when enhanced durability, finer separation, or higher throughput are needed. They are particularly useful for demanding pharma operations where particle separation must meet rigorous standards.Q: Where are these sifter sieves commonly installed within the pharma industry?

A: These sieves are widely used in industrial pharmaceutical facilities, fitted into various sifter machines for powder separation, granule grading, and quality control in tablet or capsule production lines.Q: What benefits do silicon rubber or SS bound edges provide?

A: Silicon rubber edges offer improved sealing and flexibility, reducing leakage and wear in high-vibration settings. SS bound edges enhance rigidity and longevity, providing robust performance in heavy-duty applications.Q: How does the manufacturing process ensure GMP compliance?

A: Sifter sieves are produced using laser cutting and edge-finishing technologies to achieve precise dimensions and smooth surfaces. This process, together with the use of food-grade stainless steel and hygienic construction practices, ensures full GMP compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

Sifter Sieves For Chemical Industry

Price 1000 INR / Foot

Minimum Order Quantity : 10 Feet, ,

Product Type : Sifter Sieves For Chemical Industry

Material : Stainless Steel

Usage : industrial

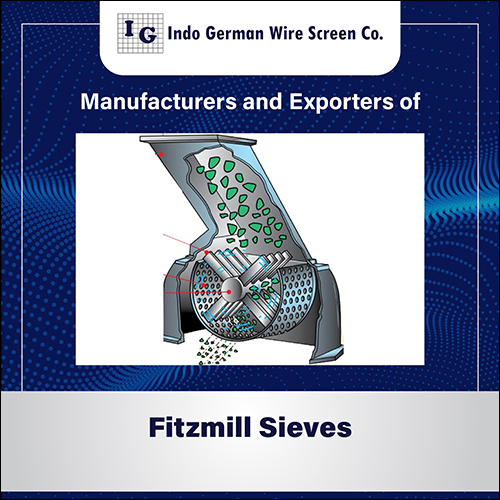

Fitzmill Sieves

Price 1000 INR / Foot

Minimum Order Quantity : 10

Product Type : Fitzmill Sieves

Material : Stainless Steel

Usage : industrial

Sieve for Conical Mills

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Product Type : Sieve for Conical Mills

Material : Stainless Steel

Usage : industrial

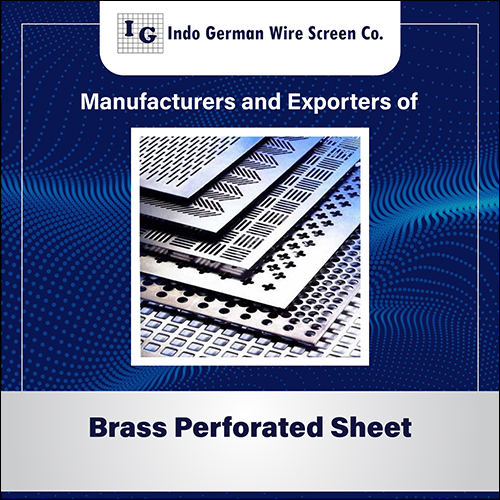

Brass Perforated Sheet IGWS75

Price Range 400.00 - 1000.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Brass Perforated Sheet

Material : Other

Usage : industrial

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry