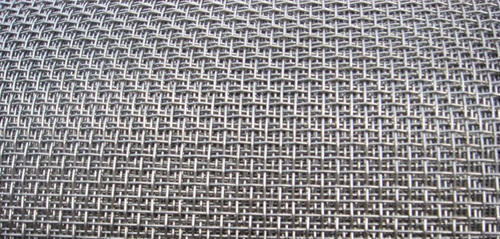

Stainless Steel Knitted Wire Screen

Stainless Steel Knitted Wire Screen Specification

- Hole Shape

- Rectangular/Irregular (due to knitted structure)

- Wire Gauge

- Standard options range from 0.10 mm to 0.35 mm

- Length

- Available in rolls; standard lengths of 10 m, 15 m, and custom sizes

- Aperture

- Variable, typically from 1 mm to 5 mm depending on knitting

- Surface Treatment

- Uncoated / Mill Finish

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Knitted Wire Mesh

- Material

- Stainless Steel

- Alloy

- SS304, SS316 and other grades on request

- Application

- Filtration, Demister Pads, Separation, Shielding, Catalyst support

- Dimensions

- Widths from 10 mm to 600 mm; custom sizes available

- Wire Diameter

- 0.10 mm - 0.35 mm

- Weight

- Varies by roll size; typically 2 kg to 10 kg per roll

- Color

- Sliver

- Elongation

- High elasticity due to knitted construction

- Corrosion Resistance

- Excellent, due to Stainless Steel material

- Standards

- ASTM, DIN or customized

- Operating Temperature

- Up to 600°C (depending on alloy used)

- Packing

- Rolls or cut pieces, plastic wrapped

- Usage Environment

- Suitable for industrial, petrochemical, pharmaceutical, and environmental applications

- Weave Type

- Knitted

About Stainless Steel Knitted Wire Screen

Application and Direction of Use

The Stainless Steel Knitted Wire Screen is expertly used for filtration, demister pads, separation, shielding, and catalyst support. Its high-elastic, flexible form enables seamless integration into industrial, petrochemical, pharmaceutical, and plant settings. To use, select the suitable roll or cut piece, fit it into the filtration or separation system, and ensure appropriate tension and positioning for optimum performance. This screen excels in demanding environments, meeting the specific needs of advanced manufacturing processes.

Export Market, Certification & FOB Details

Our Stainless Steel Knitted Wire Screen gains significant market value through widespread export to Europe, Middle East, and Asia. Backed by certifications such as ASTM and DIN, every order completion ensures top-quality compliance. We provide efficient freight options for international shipping, with main FOB ports including Mumbai and Chennai. Custom sizes and prompt packing further facilitate smooth exports, positioning us as reliable suppliers in the global marketplace.

FAQs of Stainless Steel Knitted Wire Screen:

Q: How do I install the Stainless Steel Knitted Wire Screen in my industrial application?

A: Installation involves unrolling or trimming the wire mesh to the necessary size, placing it within a housing or framework, and securing it with appropriate tension for optimal performance, depending on the plant machinery or filtration unit.Q: What are the primary advantages of using a knitted wire screen over traditional mesh types?

A: Knitted wire screens offer high flexibility, outstanding corrosion resistance, and high elasticity, making them especially suitable for environments subject to mechanical stress or high temperatures, unlike traditional woven mesh.Q: When should I choose SS304 versus SS316 for my operation?

A: Choose SS304 for general filtration and moderate corrosion applications, while SS316 is best for more corrosive environments or processes involving aggressive chemicals, due to its enhanced corrosion resistance.Q: Where can the Stainless Steel Knitted Wire Screens be applied in the manufacturing sector?

A: These screens are widely used in industrial filtration, petrochemical processing, pharmaceutical manufacturing, demister pads, shielding, and as catalyst support in various manufacturing operations.Q: What is the typical process for placing an order and ensuring a reliable shipment?

A: Contact us with your requirements; we offer instant checkout for standard sizes or discuss custom needs. Once order completion is confirmed, we arrange freight from our main FOB ports to your location, ensuring safe packing and timely delivery.Q: What benefit does the variable aperture provide in practical applications?

A: A variable aperture, typically ranging from 1 mm to 5 mm, offers flexibility for different filtration and separation requirements, allowing for customized solutions to suit specific operational needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Screen Category

Incoloy Wire Screen

Product Type : Other, Wire Screen

Material : Other, Incoloy alloy

Color : Silver

Surface Treatment : Noncorrosive polished finish, Other

Hole Shape : Other , Square

Mesh Type : Other , Wire mesh

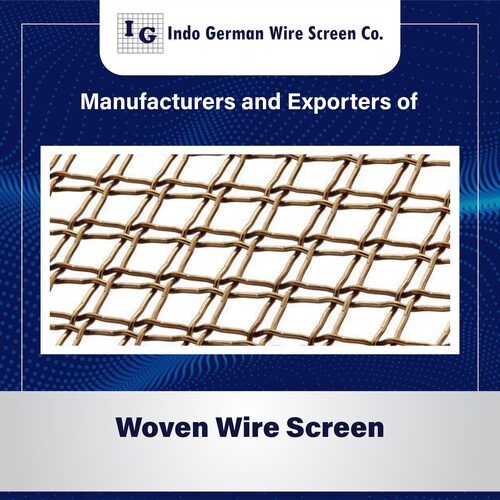

Woven Wire Screen

Product Type : Wire Mesh

Material : , Aluminum, Steel, Copper, Iron, Stainless Steel, Metal Alloys, Polyester, Galvanized Steel, Other

Color : Silver

Surface Treatment : Welding

Aluminium Wire Screen

Product Type : Wire Mesh

Material : Aluminum

Color : Sliver

Surface Treatment : Other, Galvanized / Mill Finish

Hole Shape : Other , Square

Mesh Type : Aluminum Wire

Chicken Wire Screen

Product Type : Wire Mesh

Material : Stainless Steel

Color : Sliver

Surface Treatment : Other, Galvanized or PVC coated

Hole Shape : Other , Hexagonal

Mesh Type : Steel Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry