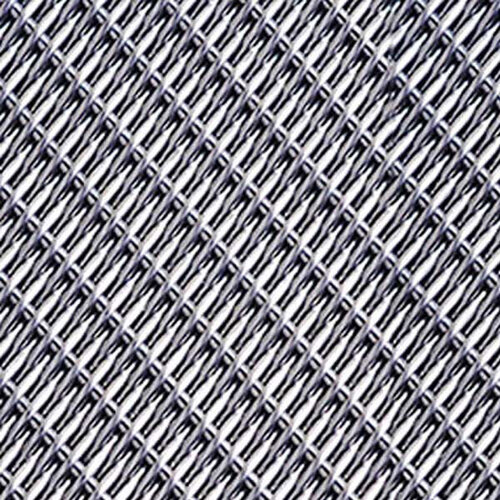

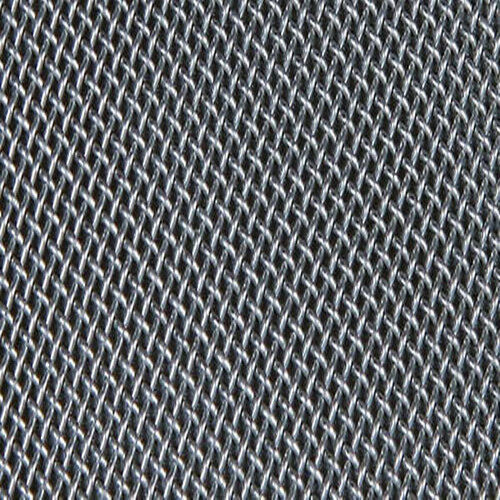

Steel Dutch Weave Wire Mesh

Price 50 INR/ Unit

MOQ : 1 Unit

Steel Dutch Weave Wire Mesh Specification

- Length

- Available in rolls up to 30 meters

- Surface Treatment

- Coated

- Hole Shape

- Rectangular

- Wire Gauge

- Customizable as per requirement

- Aperture

- Standard Dutch Weave (micro openings as per mesh count)

- Product Type

- Wire Mesh

- Mesh Type

- Dutch Weave

- Mesh Style

- Plain Mesh

- Material

- Steel

- Alloy

- Standard steel alloys (e.g., SS304, SS316)

- Application

- Other

- Dimensions

- Width up to 1.2 meters, customizable lengths

- Wire Diameter

- 0.025 mm to 0.80 mm (varies per mesh count)

- Weight

- Depends on mesh size and roll length

- Color

- Gray

- Operating Temperature

- Up to 800°C depending on alloy

- Industrial Use

- Filtration, Sieving, Sifting, Separation

- Opening Size

- 5 micron to 250 micron (as per specification)

- Standard Packing

- Waterproof paper + plastic film + wooden case

- Weave Type

- Dutch Weave

- Tensile Strength

- High tensile for industrial applications

- Corrosion Resistance

- Excellent, suitable for harsh environments

- Edge Type

- Plain or Selvage edges available

Steel Dutch Weave Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Steel Dutch Weave Wire Mesh

Nickel is a silvery-white hard metal whose strength, ductility and resistance to heat and corrosion make it exceptionally useful for the manufacturing of a wide range of materials from wires to coins to military equipment. Nickel is woven using high purity nickel wire and is mostly favoured in corrosive environments such as filtration of liquids, gas, etc.ThisNickel dutch weave wire meshis strong and stable, easy to clean and with a good flow rate suitable for high-pressure liquid/solid separation. Itis widely utilized as filter fittings for chemical industry, medicine, petroleum, scientific research units due to its stable and fine filtration ability.Precision Filtration Performance

Our steel Dutch weave wire mesh excels at micro-filtration and separation due to its precise aperture control and high tensile strength. The weaves micro openings, ranging from 5 micron to 250 micron, allow for reliable particle retention, making it an ideal choice for demanding industrial filtration systems.

Rugged Durability in Extreme Conditions

Designed with high-quality steel alloys such as SS304 and SS316, this mesh boasts excellent corrosion resistance and can operate continuously at temperatures up to 800C. Its robust construction ensures longevity even in harsh chemical or thermal environments, adding exceptional value to any filtration setup.

Tailored to Your Specifications

Customized features and dimensions are available to meet your unique needs. Select wire diameters from 0.025 mm to 0.80 mm, mesh rolls up to 30 meters in length, and widths up to 1.2 meters. Plain or selvage edge options, variety in aperture sizes, and coated surface finishes further enhance adaptability for diverse industrial processes.

FAQs of Steel Dutch Weave Wire Mesh:

Q: How is steel Dutch weave wire mesh used in industrial filtration processes?

A: Steel Dutch weave wire mesh is utilized in industrial filtration, sieving, and separation tasks where precise particle control is vital. Its micro openings efficiently trap particles ranging from 5 micron to 250 micron, making it suitable for applications in chemical processing, food production, and pharmaceuticals.Q: What are the advantages of choosing Dutch weave over other mesh types?

A: Dutch weave provides superior strength and finer particle retention compared to other mesh styles. Its unique weave structure produces a robust mesh with micro openings, ensuring reliable filtration and separation, particularly for fluids and fine powders in industrial settings.Q: When should I opt for plain or selvage edge types in wire mesh?

A: The choice between plain and selvage edge depends on application requirements. Plain edges are suitable for general use, while selvage edges are recommended when enhanced strength and fray resistance are necessary, especially for high-tension or continuous operations.Q: Where can steel Dutch weave wire mesh withstand extreme conditions?

A: This mesh is ideal for environments featuring high temperatures (up to 800C) and corrosive substances, such as petrochemical plants, water treatment facilities, and chemical processing industries. Its excellent durability and corrosion resistance ensure optimal performance under demanding conditions.Q: What is the process for customizing wire gauge and mesh dimensions?

A: Customization involves selecting wire diameter (from 0.025 mm to 0.80 mm), desired mesh opening size, roll length (up to 30 meters), and width (up to 1.2 meters). Manufacturers adjust these parameters as per specification to meet unique industrial application requirements.Q: How does the meshs surface treatment and coating benefit users?

A: The coated gray surface enhances the meshs resistance to chemical build-up, oxidation, and environmental degradation, extending its lifespan. This treatment is ideal for applications where hygiene and prolonged durability are necessary.Q: What packing methods are used for safe transport of wire mesh?

A: To safeguard the mesh during transit, it is wrapped in waterproof paper, enclosed in plastic film, and packed securely in a wooden case. This prevents damage from moisture and impact, ensuring the product reaches its destination in optimal condition.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Dutch Weave Wire Mesh Category

Stainless Steel Welded Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Plain Mesh

Material : Stainless Steel

Color : Gray

Product Type : Wire Mesh

Nichrome A Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Dutch Weave Wire Mesh

Material : Other, Nichrome

Color : Gray

Product Type : Wire Mesh

Brass Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Dutch Weave Wire Mesh

Material : Other, Brass

Color : Gray

Product Type : Wire Mesh

Monel 400 Dutch Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Mesh Style : Other , Dutch Weave Wire Mesh

Material : Other, Monel

Color : Gray

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry