Tungsten Plain Weave Wire Mesh

Price 50 INR/ Unit

Tungsten Plain Weave Wire Mesh Specification

- Length

- 1 m to 30 m per roll (as required)

- Surface Treatment

- Annealed / Polished

- Hole Shape

- Square

- Wire Gauge

- 10 to 325 mesh (customizable)

- Aperture

- 0.038 mm to 2.03 mm

- Product Type

- Plain Weave Wire Mesh

- Mesh Type

- Woven

- Mesh Style

- Plain Weave

- Material

- 100% Pure Tungsten

- Alloy

- W1, W2

- Application

- Filtration, Shielding, Heating, Laboratory, Chemical, and Electronics industries

- Dimensions

- Width: 0.5 m to 1.2 m (custom sizes available)

- Wire Diameter

- 0.025 mm to 1.6 mm

- Weight

- Varies per mesh size and dimensions

- Color

- Silver Gray

- Conductivity

- High electrical and thermal conductivity

- Tensile Strength

- 1510 MPa

- Form

- Roll, Sheet, or Cut Piece

- Melting Point

- 3410°C

- Standard Packing

- Rolls with moisture-proof paper, wooden case

- Corrosion Resistance

- Excellent against acids and alkalis

- Temperature Resistance

- Up to 3400°C

About Tungsten Plain Weave Wire Mesh

Tungstenis an extremely hard metallic element that can be woven into wire mesh and wire cloth. Tungsten has an extremely high melting point and is corrosion resistant in many harsh environments. Tungsten Mesh is resistant to oxidation attack and corrosion in acidic and alkaline media.Warp wire- It runs in the direction of mesh length.Each weft wire goes alternatively over and under each warp wire, and vice versa.Tungsten Plain Weave Wire Meshesare available with apertures from 10.7 mm (2 mesh) to 0.05 mm (325 mesh). Its very easily cleanable with identical apertures and It can be easily cut and shaped, and quick to unroll & install.

Exceptional Durability and Resistance

Engineered for demanding conditions, tungsten plain weave wire mesh withstands extreme temperatures and corrosive environments, making it ideal for filtration and shielding applications in chemical and electronic industries. Its robust tensile strength and surface options (annealed or polished) further enhance durability.

Versatile Form Options and Customization

This mesh is supplied in rolls, sheets, or cut pieces with customizable dimensionswidths from 0.5 m to 1.2 m and lengths up to 30 mto suit specific requirements ranging from laboratory experiments to industrial-scale operations. Various mesh styles and apertures allow precise application matching.

High Conductivity for Advanced Applications

With superior electrical and thermal conductivity, this wire mesh is especially valued for scientific, heating, and electronic uses. The pure tungsten construction ensures minimal loss of performance under high-stress conditions, supporting intricate and sensitive technological operations.

FAQs of Tungsten Plain Weave Wire Mesh:

Q: How is tungsten plain weave wire mesh manufactured for industrial use?

A: Tungsten plain weave wire mesh is created by weaving pure tungsten wires (W1 or W2 alloys) in a crisscross pattern, resulting in a strong, uniform mesh. The surface can be annealed or polished, and mesh sizes, wire diameters, and dimensions are customized to customer specifications for various industrial applications.Q: What are the main benefits of using this mesh in corrosive environments?

A: Thanks to its excellent corrosion resistance against acids and alkalis, tungsten wire mesh is highly durable and retains structural integrity even in aggressive chemical environments, making it ideal for filtration and protection in laboratories, electronics, and chemical industries.Q: Where is tungsten plain weave wire mesh most effectively utilized?

A: This mesh finds optimal use in high-temperature filtration, heating systems, laboratory shielding, and electronic devices. Its robust temperature and corrosion resistance make it a reliable choice for industries requiring stability under extreme or hazardous conditions.Q: When should I choose tungsten mesh over other metal meshes?

A: Select tungsten mesh when applications demand resistance to very high temperatures (up to 3400C), high tensile strength, and superior conductivity. Its inertness and durability outperform other metals in specialized scientific, filtration, and electronic projects.Q: What customization options are available for tungsten mesh?

A: Tungsten wire mesh can be ordered in various forms including rolls, sheets, or cut-to-size pieces. Customization extends to mesh size (10 to 325 mesh), wire diameter (0.025 mm to 1.6 mm), aperture (0.038 mm to 2.03 mm), and dimensions (widths 0.5 m1.2 m, lengths up to 30 m).Q: How should I store and handle tungsten wire mesh after delivery?

A: The mesh is packed in rolls with moisture-proof paper and robust wooden cases to prevent contamination and oxidation. It should be stored in a dry, clean environment and handled with gloves to avoid damaging the surface or introducing pollutants.Q: What processes can this mesh withstand during use or fabrication?

A: Tungsten mesh tolerates high-temperature processes, including heating, annealing, and exposure to direct flame. It also withstands contact with most acids and bases, maintaining integrity during cutting, shaping, or surface treatments required for specialized projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plain Weave Wire Mesh Category

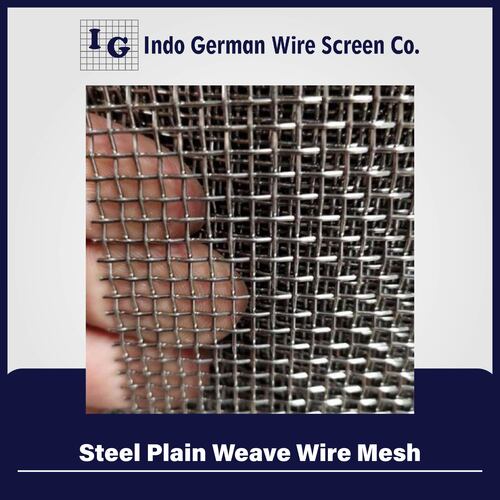

Steel Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Surface Treatment : Coated

Mesh Style : Plain Mesh

Color : Gray

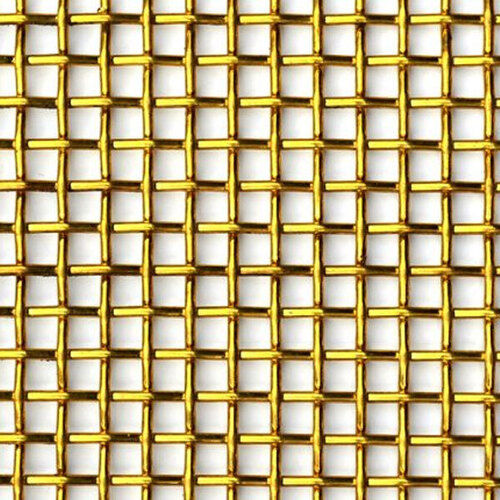

Brass Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Brass

Surface Treatment : Coated

Mesh Style : Plain Mesh

Color : Golden

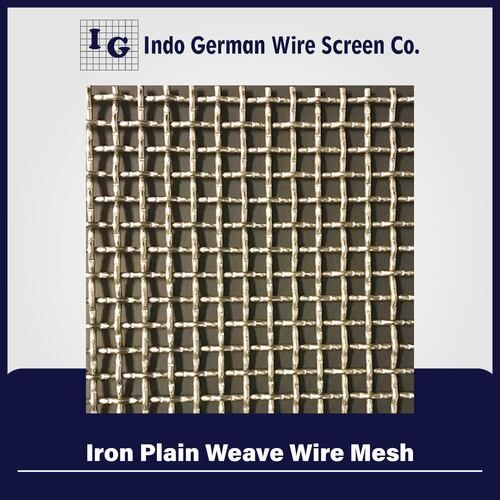

Iron Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Iron

Surface Treatment : Coated

Mesh Style : Plain Mesh

Color : Gray

Bronze Plain Weave Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Bronze

Surface Treatment : Coated

Mesh Style : Plain Weave, Other

Color : Bronze

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry