Vibrating Screen Wire Cloth

Price 400.00-100000.00 INR/ Foot

Vibrating Screen Wire Cloth Specification

- Hole Shape

- Square Hole

- Product Type

- Wire Mesh

- Mesh Type

- Iron Wire Mesh

- Material

- Copper, , Steel, Stainless Steel, Metal Alloys, Polyester, Iron, Aluminum, Galvanized Steel

- Color

- Silver

Vibrating Screen Wire Cloth Trade Information

- Minimum Order Quantity

- 50 Feet, ,

- FOB Port

- mumbai

- Payment Terms

- Letter of Credit (L/C), Paypal, Cash in Advance (CID), Cheque

- Supply Ability

- 10000 Feet, , Per Week

- Delivery Time

- 7 Days

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Vibrating Screen Wire Cloth

Features:- High-quality alloy and metal for better corrosion resistance

- Dimensional accuracy and perfect mesh opening to facilitate proper screening

- High tensile strength to support heavy inlet of screening material

Product details

|

Country of Origin |

Made in India |

|

Material |

Stainless Steel |

|

Usage |

Industrial |

|

Hole Shape |

Square,Circular |

|

Material Grade |

SS 304, 316 |

Superior Construction for Versatile Applications

Crafted with precision, our vibrating screen wire cloth is tailored for high efficiency in material separation. The square holes and robust wire mesh construction make it ideal for mining, construction, and processing industries. Multiple material options ensure adaptability to demanding environments and diverse usages.

Quality Assurance and Customization

We rigorously test our wire cloths for durability, corrosion resistance, and optimal mesh sizing. As a reputable supplier and exporter, we also offer customization in dimensions and material to suit your machinery and processing needs, ensuring reliable performance and longevity.

FAQs of Vibrating Screen Wire Cloth:

Q: How is the vibrating screen wire cloth manufactured?

A: The wire cloth is manufactured using advanced weaving techniques that shape iron wires into a square hole mesh. Material selection can include copper, steel, stainless steel, galvanized steel, aluminum, polyester, and other metal alloys, ensuring strength and corrosion resistance.Q: What are the benefits of using square hole mesh in vibrating screens?

A: Square hole mesh provides precise and efficient particle separation, prevents clogging, and supports consistent throughput in screening applications. It enhances screening accuracy and reduces downtime in industrial processes.Q: When should I choose galvanized steel or stainless steel for my wire mesh?

A: Galvanized steel is suitable for environments prone to rust or moisture, providing good corrosion resistance. Stainless steel is ideal for highly corrosive or high-temperature settings, offering enhanced durability and longevity.Q: Where can this vibrating screen wire cloth be used?

A: It is widely applied in mining, aggregate processing, construction, chemical, and food industries for sorting, sizing, and filtration tasks. Its adaptability in material composition allows usage in various operational settings.Q: What is the process for customizing mesh size and materials?

A: Clients specify their requirements regarding mesh size, wire diameter, and preferred materials. We then manufacture the wire cloth to meet those exact specifications, ensuring optimal compatibility with their screening machinery.Q: How is this wire mesh advantageous for exporters, manufacturers, and traders in India?

A: It offers high versatility and can be tailored to meet international standards and local industry needs, giving businesses in India a competitive advantage in both domestic and global markets.Q: What maintenance is required for vibrating screen wire cloth?

A: Regular inspection for signs of wear, cleaning to remove debris, and timely replacement of damaged sections help maintain efficiency. Material choice can minimize maintenance needs, especially in harsh environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Cloth Category

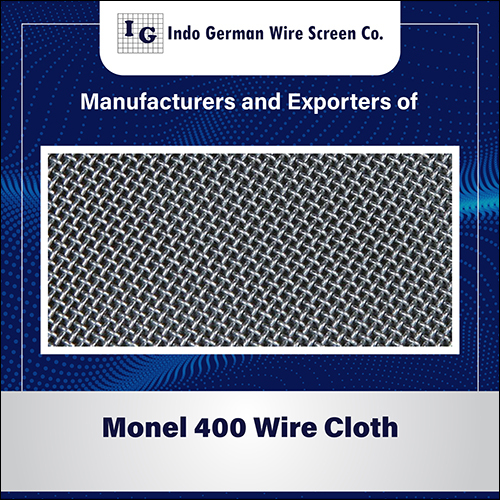

Monel 400 Wire Cloth

Material : Other, Monel

Product Type : Wire Cloth

Surface Treatment : Polished

Mesh Type : Iron Wire Mesh

Color : Sliver

Hole Shape : Other , Square

Twill Dutch Weave Wire Cloth

Material : Stainless Steel

Product Type : Wire Cloth

Surface Treatment : Mill Finish

Mesh Type : Steel Wire Mesh

Color : Sliver

Hole Shape : Other , Hexagonal

Dutch Weave Wire Cloth

Material : Stainless Steel

Product Type : Wire Cloth

Surface Treatment : Polished

Mesh Type : Iron Wire Mesh

Color : Sliver

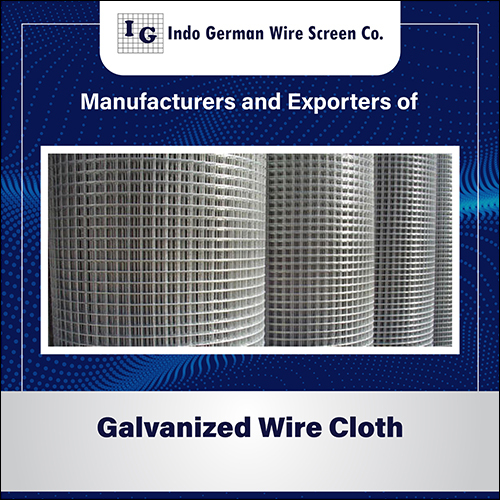

Galvanized Wire Cloth

Material : Other, Galvanized Iron

Product Type : Wire Mesh

Surface Treatment : Polished

Mesh Type : Steel Wire Mesh

Color : Sliver

Hole Shape : Square Hole

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry