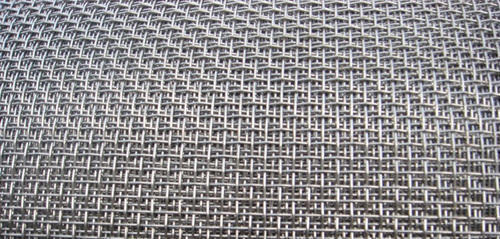

Vibrating Screen Wire Netting

Vibrating Screen Wire Netting Specification

- Wire Gauge

- Not Provided

- Surface Treatment

- Not Provided

- Hole Shape

- Square or rectangular

- Length

- Not Provided

- Aperture

- Not Provided

- Product Type

- Wire Netting

- Mesh Type

- Vibrating Screen Wire Netting

- Mesh Style

- Woven

- Material

- Alloy

- Not Provided

- Application

- Screening and filtering in industries

- Dimensions

- Not Provided

- Wire Diameter

- Not Provided

- Weight

- Not Provided

- Color

- Metallic

About Vibrating Screen Wire Netting

Our company deals in the manufacturing and supplying of premium grade Vibrating Screen Wire Netting that is designed and developed by our team of professional engineers using advanced production technologies and heavy engineering materials that result in high tensile and compressive strength to bear harsh industrial conditions. It can be used in wide range of industrial and commercial applications. The offered Vibrating Screen Wire Netting availed by us can be customized according to customer demands and application areas.

Superior Screening Performance

Designed for industrial applications, Vibrating Screen Wire Netting stands out for its ability to provide precise separation and filtration of materials. Its woven mesh style and tailored hole shapes offer optimal operation in mining, chemical, and construction industries, ensuring consistent results and enhanced productivity.

Durable and Reliable Material

Crafted from wire mesh materials such as stainless steel, Vibrating Screen Wire Netting is built to withstand harsh working conditions and resist corrosion. This ensures a longer service life and consistent performance, making it a cost-effective choice for various demanding industrial processes.

Versatile Industrial Applications

From screening aggregates to filtering liquids and solids, this wire netting adapts efficiently to diverse industrial operations. Its flexibility in mesh type and shape makes it suitable for use in mining, food processing, chemical plants, and construction sites across India.

FAQs of Vibrating Screen Wire Netting:

Q: How is Vibrating Screen Wire Netting used in industrial screening and filtering?

A: Vibrating Screen Wire Netting is installed on screen equipment, where it vibrates to separate, classify, or filter materials by passing them through woven mesh with square or rectangular holes, facilitating efficient sorting in various industries.Q: What benefits does stainless steel wire mesh offer in Vibrating Screen Wire Netting?

A: Stainless steel wire mesh provides high resistance to corrosion, mechanical strength, and longevity, making it ideal for heavy-duty industrial use. Its durability ensures reliable performance and reduces maintenance frequency.Q: Where can Vibrating Screen Wire Netting be applied in industrial operations?

A: This wire netting is widely used in industries such as mining, construction, chemical processing, and food manufacturing, wherever precise screening or filtering of materials is required for production or quality control.Q: What is the process for selecting the right Vibrating Screen Wire Netting for my application?

A: Selection involves considering factors like required mesh size, hole shape (square or rectangular), material properties, and the nature of the substances to be screened or filtered, ensuring optimal performance for your process.Q: When should Vibrating Screen Wire Netting be replaced or maintained?

A: Regular inspection is recommended, especially in high-wear environments. Netting should be replaced or maintained when signs of damage, wear, or reduced screening efficiency are observed to maintain safety and productivity.Q: How does the woven mesh style benefit the screening process?

A: The woven mesh style enhances strength and flexibility, ensuring consistent aperture openings. This design supports efficient separation and prevents clogging, leading to improved throughput in screening operations.Q: What makes Vibrating Screen Wire Netting a suitable choice for exporters, suppliers, and manufacturers in India?

A: Its adaptability for various industrial needs, robust construction using quality wire mesh, and compatibility with international standards make it a reliable option for businesses seeking quality screening solutions across different sectors.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Wire Netting Category

Incoloy Wire Netting

Product Type : Wire Netting, Other

Material : Other, Incoloy Alloy

Mesh Type : Fine mesh, Other

Color : Silver

Surface Treatment : Other, Nongalvanized

Hole Shape : Other , Square

Spring Steel Wire Netting

Product Type : Wire Mesh

Material : Other, Spring Steel

Mesh Type : Other , Wire Netting

Color : Sliver

Hole Shape : Square Hole

Knitted Wire Netting

Product Type : Wire Mesh

Material : Stainless Steel

Mesh Type : Other , Knitted Wire Netting

Surface Treatment : Polished

Hole Shape : Other , Square, Diamond, Hexagonal

Brass Wire Netting

Product Type : Wire Mesh

Material : Other, Brass

Mesh Type : Other , Brass Wire Netting

Color : Brass

Surface Treatment : Polished

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry