Wire Mesh Disc

Price 250 INR/ Piece

Wire Mesh Disc Specification

- Wire Gauge

- 24 to 30 SWG (Standard Wire Gauge)

- Length

- Customizable; typically up to 500 mm

- Surface Treatment

- Polished

- Hole Shape

- Round

- Aperture

- 0.5 mm to 2.5 mm

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Single-layer or multi-layer

- Material

- Steel

- Alloy

- Mild Steel, Stainless Steel (SS304/SS316)

- Application

- Other

- Dimensions

- Available diameters: 25 mm, 50 mm, 75 mm, 100 mm, 150 mm, custom options

- Wire Diameter

- 0.4 mm to 0.8 mm

- Weight

- Depends on dimension; standard discs weigh between 5 g to 120 g

- Color

- Silver

Wire Mesh Disc Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 10 Pieces Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Wire Mesh Disc

Wire Mesh Filter Discselection is based on the application, characteristics of material to be filtered, process goal etc. asWire Mesh Filter Discis one of the important elements in filtration using filter press. The Filter Discs come in many different materials including polypropylene, cotton, polyester, and other synthetic materials. We supplyWire Mesh Filter Discbased on our previous experience or by taking filtration trials with the taster slurry given by the customer. The cloths are made from multifilament fibres, monofilament fibres, or spun fibres with different weave patterns such as twill weave, plain weave etc. The clothes will be finished in numerous ways like Heat set, calendared, single-glazed to facilitate easy cake release.

Enhanced Filtration Performance

Designed for optimal filtration, Wire Mesh Discs ensure efficient separation and particle retention in demanding environments. Their multi-layered construction and precise wire gauge selection guarantee durability and reliability, supporting extended usage in chemical and industrial processes.

Versatility in Industrial Applications

With customizable diameters, mesh types, and edge styles, these discs are suitable for a variety of processes, including chemical filtration, powder screening, and gas purification. They can be tailored to fit specific machinery or operational requirements, offering flexibility for manufacturers and exporters.

Long-Lasting Corrosion Resistance

Manufactured from high-grade stainless steel or mild steel, our discs maintain integrity even under continuous exposure to corrosive substances or elevated temperatures. The polished surface treatment further enhances resistance, reducing maintenance needs and prolonging product life.

FAQs of Wire Mesh Disc:

Q: How are wire mesh discs manufactured for industrial use?

A: Wire mesh discs are produced using woven or sintered techniques, with each method tailored for specific filtration requirements. The discs are made from steel wire mesh, which is precision cut, shaped into discs, and treated with a polished finish for improved corrosion resistance and durability.Q: What benefits do wire mesh discs offer in chemical processing applications?

A: These discs provide high corrosion resistance and reliable operation at temperatures up to 400C, making them ideal for chemical processing environments. Their customizable dimensions and mesh styles support effective filtration, separation, and screening tasks.Q: When should wire mesh discs be replaced during industrial operations?

A: Wire mesh discs generally have a service life of two to five years, depending on application conditions and maintenance practices. Replacement is recommended when the mesh shows signs of clogging, wear, or decreased filtration efficiency.Q: Where can custom-sized wire mesh discs be obtained in India?

A: Custom-sized wire mesh discs are available through manufacturers, suppliers, traders, and exporters in India. These providers offer a range of diameters, mesh types, and edge configurations to suit specific operational requirements.Q: What is the usage process for wire mesh discs in filtration systems?

A: Wire mesh discs are inserted into filtration units or process machinery. Depending on the system, they function as primary or secondary filters, trapping particles while allowing fluids or gases to pass through their woven or sintered mesh structure.Q: How does the surface treatment of wire mesh discs enhance their performance?

A: The polished surface treatment improves corrosion resistance and facilitates easier cleaning. This extends the operational life of the discs and maintains consistent filtration quality over extended periods.Q: What are the main advantages of choosing stainless steel wire mesh discs over mild steel?

A: Stainless steel discs (SS304/SS316) offer superior corrosion resistance and strength, making them preferable for harsh chemical environments or prolonged exposure to moisture. Mild steel options are effective for less demanding applications where cost efficiency is a priority.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

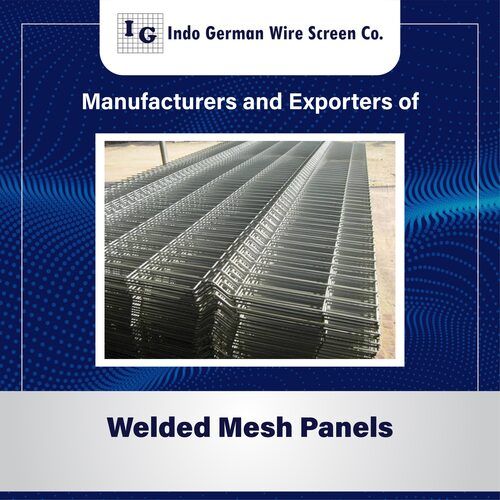

Welded Mesh Panels

Price 120 INR

Minimum Order Quantity : 10 Square Meters

Color : Sliver

Material : Other, Low Carbon Steel / Stainless Steel

Product Type : Wire Mesh

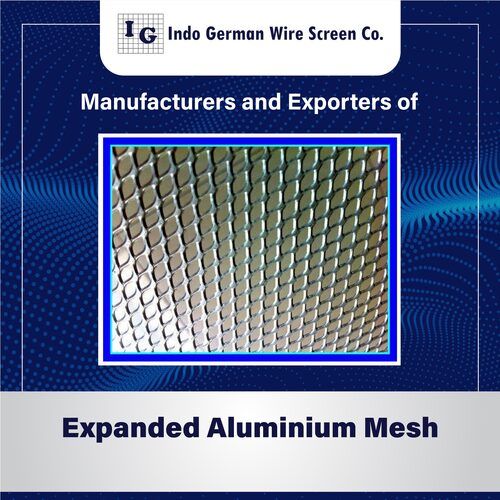

Expanded Aluminum Mesh

Price Range 18.00 - 30.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Color : Silver

Material : Aluminum

Product Type : Wire Mesh

SS Wire Mesh For Hydraulic Filters

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Color : Black

Material : Stainless Steel

Product Type : Wire Mesh

Stainless Steel Wire Screen

Price Range 4000.00 - 15000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Color : Black

Material : Stainless Steel

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry