Wire Mesh Filter Pads

Price 50 INR/ Unit

MOQ : 1 Unit

Wire Mesh Filter Pads Specification

- Surface Treatment

- Coated

- Product Type

- Wire Mesh

- Mesh Type

- Wire Mesh Filter Pads

- Mesh Style

- Epoxy Coated Wire Mesh

- Material

- Application

- Other

- Color

- Gray

Wire Mesh Filter Pads Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About Wire Mesh Filter Pads

Wire Mesh Filter Padsare available in different sizes and wide-range can be customized to fit your exact specifications in order to meet your specific application requirements. We offer an exclusive range ofWire Mesh Filter Padsat unmatched quality and market leading prices.Wire Mesh Filter Padsare widely used in breweries, distilleries, wineries, Chemical, pharmaceutical companies and transformer oil filtration and many more uses and find applications in a wide range of industries according to mesh sizes and materials.We have become a major supplier of these products into an extensive range of markets and applications across India and the globe. Our clients select our range of products for their economical prices, dimensional preciseness, and high-durability. At Indo German Wire Screen Co.,Durable Epoxy Coating

The epoxy-coated surface treatment not only adds an extra layer of protection against corrosion but also bolsters the longevity of these wire mesh filter pads. This makes them ideal for environments where chemical and moisture exposure are prevalent. As a result, users benefit from reduced maintenance needs and a cost-effective filtration solution.

Versatile Filtration Performance

Owing to their special mesh construction and high-grade materials, these filter pads accommodate a wide spectrum of industrial filtration requirements. Their unique mesh style enables precise retention of particulates, making them adaptable for customized filtration setups across diverse sectors.

FAQs of Wire Mesh Filter Pads:

Q: How are epoxy coated wire mesh filter pads manufactured?

A: Epoxy-coated wire mesh filter pads are fabricated by weaving high-quality wire into the desired mesh style and then applying a layer of epoxy coating. This process ensures enhanced protection against corrosion and increases the pads durability for industrial use.Q: What are the main benefits of using coated wire mesh filter pads?

A: The primary benefits include superior corrosion resistance, extended lifespan, and consistent filtration performance. The epoxy coating provides an added barrier against harsh chemicals and moisture, making these pads suitable for a wide range of demanding industrial applications.Q: When should I choose epoxy coated wire mesh pads over uncoated ones?

A: Epoxy coated wire mesh pads are recommended when your filtration system operates in environments exposed to moisture, chemicals, or requires longer service intervals. The coating significantly reduces the risk of rust and degradation compared to uncoated alternatives.Q: Where can these wire mesh filter pads be used effectively?

A: These filter pads are widely applicable in chemical processing, pharmaceuticals, food and beverage manufacturing, HVAC systems, and other industries that demand reliable particulate filtration and durability against challenging operating conditions.Q: What is the typical process for installing a wire mesh filter pad?

A: Installation generally entails placing the filter pad within the designated housing or frame, securing it to prevent bypass, and ensuring a proper fit for optimal performance. It is advisable to follow the system manufacturers instructions for specific installation steps.Q: How do coated wire mesh filter pads enhance system efficiency?

A: The specially designed mesh and epoxy coating prevent clogging and degradation, providing steady and efficient filtration over time. This reduces downtime and maintenance, ensuring smooth operation and lower ownership costs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Epoxy Coated Wire Mesh Category

Aluminium epoxy coated Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other, Aluminium

Product Type : Other, Aluminium Epoxy Coated Wire Mesh

Mesh Type : Aluminum Wire Mesh

Mesh Style : Other

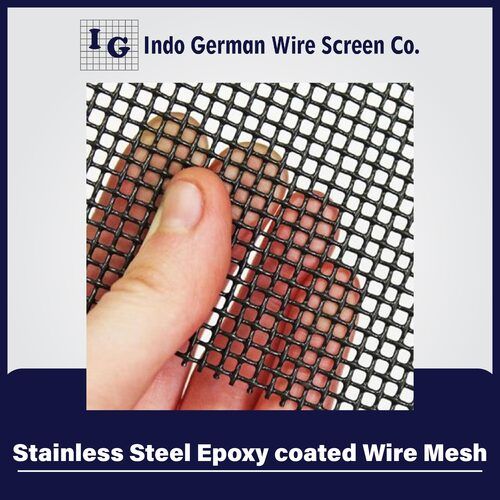

Stainless Steel Epoxy coated Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Stainless Steel

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Mesh Style : Other

Steel epoxy coated Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Product Type : Wire Mesh

Mesh Type : Steel Wire Mesh

Mesh Style : Other

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry