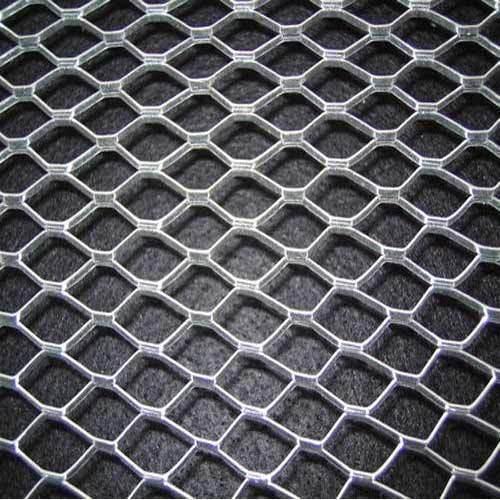

Wire Screens

Wire Screens Specification

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Material

- Steel

- Application

- Screen, Food Industry

- Color

- Silver

Wire Screens Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Square Meters Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Wire Screens

Wire Screens are used to be applied on doors & windows for maintaining proper air circulation & ventilation in both commercial & residential sectors. They are also considered to be best for use as fencing in high-security areas & forest. These screens are made of superior quality galvanized steel alloy using the latest welding technology so as to assure strong structural configuration with great impact resistance. It is hassle-free to install and shows the ability to bear various climatic conditions without much structural wear & abrasion. Wire Screens are also perfect for use in sports stadiums as a protective barrier around the field.

Special Features :

- Offered screens are available with twill weave or plain weave or reverse Dutch weave type pattern based option.

- These screens are acid and alkali protected.

- Wear proof surface, excellent strength, good toughness level

- Ideal for filtering and screening procedures under alkaline and acidic conditions

Product Details

|

Material Grade |

Stainless Steel |

|

Usage |

Industrial,Agricultural,Defence |

|

Size |

Customize |

Versatile Solutions for Diverse Industries

Our steel wire mesh screens serve a wide array of usages, particularly excelling in food industry applications and screening tasks. Their resilience and reliability make them suitable for sorting, filtering, and safety in manufacturing environments. Backed by strict quality controls, we deliver consistent performance and long-lasting service through our robust supply and export network in India.

Quality Assurance and Material Benefits

Constructed entirely from high-grade steel, each mesh screen boasts a silver appearance and superior resistance to rust. This ensures food safety, effortless cleaning, and stable structural integrity over time. Our meticulously crafted meshes undergo precision processes, providing customers with products compliant with international standards and capable of withstanding rigorous industrial demands.

FAQs of Wire Screens:

Q: How is steel wire mesh used in the food industry?

A: Steel wire mesh is extensively utilized in the food industry for filtering, sieving, and separating solids from liquids or other materials. Its corrosion resistance and ease of cleaning make it ideal for maintaining hygiene and safety standards during food processing tasks.Q: What are the benefits of choosing steel wire mesh screens for screening applications?

A: Steel wire mesh screens offer exceptional durability, resistance to wear and corrosion, and precise filtration or screening capability. Their versatility makes them suitable for both industrial screening and food processing, ensuring efficient operation and minimal maintenance.Q: When should I use silver-colored steel mesh instead of other materials or finishes?

A: Silver-colored steel mesh is recommended when you need excellent corrosion resistance, food safety, and a clean appearance. This makes it especially suited for food industry settings or environments with high moisture or strict sanitation requirements.Q: Where can I obtain steel wire mesh screens for industrial or food-related use?

A: We supply, manufacture, and export steel wire mesh screens throughout India and internationally. Customers can contact us directly for tailored solutions, bulk orders, or specific requirements related to their manufacturing processes.Q: What is the process for manufacturing steel wire mesh screens?

A: Manufacturing steel wire mesh involves weaving or welding high-quality steel wires to form a consistent mesh size and pattern. The process is closely monitored for quality assurance, ensuring the final product meets regulatory and application-specific standards.Q: How do I maintain and clean steel wire mesh in food industry applications?

A: To ensure longevity and hygiene, steel wire mesh should be cleaned regularly using mild detergents and water or food-safe cleaning solutions. Avoid harsh chemicals that could damage the silver finish or contaminate food products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Black Wire Cloth

Price 14 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Color : Black

Material : Iron

Mesh Type : Other

SS Wire Mesh For Hydraulic Filters

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Color : Black

Material : Stainless Steel

Mesh Type : Steel Wire Mesh

Twill Dutch Weave Wire Mesh

Price 130 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Color : Silver

Material : Steel

Mesh Type : Steel Wire Mesh

PVC Welded Wire Mesh

Price Range 12.00 - 30.00 INR / Square Foot

Minimum Order Quantity : 200 Square Foots

Color : Green

Material : Steel

Mesh Type : Steel Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry