17 7 PH Stainless Steel Mesh

17 7 PH Stainless Steel Mesh Specification

- Hole Shape

- Square

- Surface Treatment

- Passivated

- Wire Gauge

- 24 SWG

- Aperture

- 0.95 mm

- Length

- 30 meter roll

- Product Type

- Stainless Steel Mesh

- Mesh Type

- Other

- Mesh Style

- Other

- Material

- 17-7 PH Stainless Steel

- Alloy

- 17-7 PH

- Application

- Filtration, Sieving, Screening

- Dimensions

- 1 meter width x 30 meter length

- Wire Diameter

- 0.56 mm

- Weight

- Approx. 5 kg per roll

- Color

- Silver

17 7 PH Stainless Steel Mesh Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Supply Ability

- 10 Square Meters Meter Per Day

- Delivery Time

- 1 Week

About 17 7 PH Stainless Steel Mesh

Product Details:

| Material | 17 7 ph SS |

| Mesh Size(per inch) | 0-10 , 100-150, 150-200, 10-50, 50-100 |

| Weave Type | Twill, PSW |

| Condition | New |

| Grade | 17-7 ph Stainless steel |

| Rust Proof | Yes |

UNS S17700

17-7 PH stainless steel wire cloth has good workability in the annealed condition, corrosion resistance, and excellent fatigue properties.

Composition [Cr 16-18%, Ni 6.5-7.75%, C 0.09%]

Specifications AMS 5678

Superior Corrosion Resistance and Strength

Engineered from 17-7 PH stainless steel, this mesh offers excellent resistance to harsh chemicals and oxidation, ensuring longevity and consistent performance. Its high tensile and yield strength make it exceptionally durable even under demanding mechanical stresses. The passivated surface provides additional stability, making it ideal for applications requiring reliability and resilience.

Precision Filtration and Sieving Solution

With a wire diameter of 0.56 mm and an aperture of 0.95 mm, the mesh delivers accurate filtration, sieving, and screening results. The woven manufacturing process ensures uniformity throughout the roll, which spans 1 meter in width and 30 meters in length. This consistency is vital for industries where product quality is crucial, such as food, chemical processing, and pharmaceuticals.

Versatility Across Multiple Industries

The 17-7 PH stainless steel mesh excels in environments where high temperature and corrosion resistance are required. It is widely used in chemical filtration, food processing, aerospace component manufacturing, and pharmaceutical applications due to its adaptability and robust characteristics. Its semi-magnetic nature also lends itself to specialized industrial uses.

FAQs of 17 7 PH Stainless Steel Mesh:

Q: How is the 17-7 PH Stainless Steel Mesh manufactured?

A: This mesh is produced using a precision woven process, resulting in uniform wire spacing and consistent apertures. The finished product features a matte surface and cut edges, ensuring clean installation and reliable filtration performance.Q: What industries commonly use 17-7 PH Stainless Steel Mesh?

A: It is utilized in the chemical, food, aerospace, and pharmaceutical industries, where high corrosion resistance, mechanical strength, and precise filtration are essential for operational success.Q: When should I use 17-7 PH Stainless Steel Mesh over other grades?

A: Choose this mesh when your application requires high tensile and yield strength, excellent corrosion resistance, and reliability at elevated temperatures up to 600C. Its particularly recommended for challenging filtration and sieving tasks.Q: Where can the mesh be installed or applied?

A: 17-7 PH mesh is suited for use in filtration, sieving, and screening equipment within processing plants, laboratories, aerospace assemblies, and manufacturing facilities where robust performance is critical.Q: What is the benefit of passivation for this mesh?

A: Passivation enhances the meshs natural resistance to chemical attack and oxidation, providing an extra layer of protection and prolonging its functional lifespan in corrosive environments.Q: How does the meshs semi-magnetic property affect its usage?

A: The semi-magnetic attribute allows it to be used in applications where some magnetic responsiveness is useful, but where complete magnetism may interfere with processes or safety requirements.Q: What is the recommended process for installing the mesh in filtration systems?

A: Use the mesh roll by cutting sections to fit your filtration unit, ensuring the cut edges are handled carefully. Its uniform dimensions and flexibility allow easy customization and integration into existing systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

Wire Mesh For Food Processing and Preparation

Price 1000-100000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Mesh Type : Steel Wire Mesh

Surface Treatment : Galvanized

Product Type : Wire Mesh

Rectangle Wire Mesh

Price 120 INR / Square Foot

Minimum Order Quantity : 10 Square Meters

Mesh Type : Steel Wire Mesh

Surface Treatment : Polished

Product Type : Wire Mesh

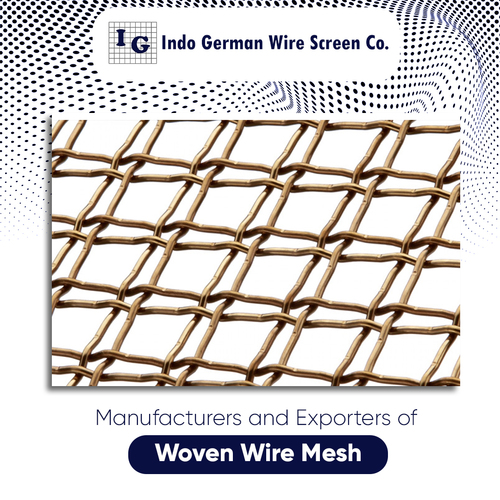

Woven Wire Mesh

Price 50 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Mesh Type : Aluminum Wire Mesh

Surface Treatment : Polished

Product Type : Wire Mesh

Woven Wire Cloth

Price Range 50.00 - 100.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Mesh Type : Steel Wire Mesh

Surface Treatment : Polished

Product Type : Wire Cloth

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry