Rectangle Wire Mesh

Price 120 INR/ Square Foot

Rectangle Wire Mesh Specification

- Aperture

- Adjustable, commonly 6 mm x 12 mm to 50 mm x 100 mm

- Length

- As per requirement, typically 10 m to 30 m rolls

- Wire Gauge

- Available in 8 to 24 gauge

- Hole Shape

- Rectangle Hole

- Surface Treatment

- Polished

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Welded or woven rectangular mesh

- Material

- Galvanized Iron, Stainless Steel, or Low Carbon Steel

- Alloy

- Can be available in various stainless steel grades such as SS304/SS316

- Application

- Fencing, security, sieving, cage making, construction, agricultural use

- Dimensions

- Standard sizes or custom as required

- Wire Diameter

- Ranges from 0.5 mm to 2.5 mm

- Weight

- Varies with size and material, approximately 2 kg to 30 kg per roll

- Color

- Sliver

Rectangle Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Supply Ability

- 10 Square Meters Per Day

- Delivery Time

- 1 Week

About Rectangle Wire Mesh

Product Details:

| Mesh Size(per inch) | 50-100 , 100-150, 150-200, 0-10, 10-50 |

| Material | SS316, Fine SS |

| Surface Finish Coating | Black Powder |

| Type | Expanded Wire Mesh |

| Weave Type | PSW |

We are engaged in offering our clients with a qualitative range of Rectangular Wire Mesh. These rectangular wire meshes have weaves with exact ultra fine openings and are available in 15 microns. Our range comprises a sturdy body and is used for filtering, shifting and grading of chemicals, sugar gardens, powers, minerals and graders. Moreover, we also offer these in varied specifications to meet the requirements of our clients.

Features:

- Fine Finish

- Light in weight

- Quality approved

Yes! I am Interested

Exceptional Adaptability and Performance

Rectangle Wire Mesh offers excellent adaptability with customizable dimensions, wire gauge (824), and apertures. The product is available in a range of materials, including stainless steel for high corrosion resistance. Diverse edge options and surface treatments further enhance durability, making it suitable for environments demanding reliability and strength.

Tailored Packaging and Reliable Supply

Our wire mesh is neatly packed in rollstypically 10 to 30 meterswith waterproof protection or custom packaging to suit your needs. Whether you require sheets or rolls, standard sizes, or bespoke specifications, our flexible manufacturing and export services, based in India, ensure prompt and reliable supply to your project.

Versatile Applications

Rectangle Wire Mesh is ideal for fencing, security barriers, sieving processes, animal cages, agriculture, and construction reinforcements. Its robust build and corrosion-resistant materials expand its usefulness, particularly where durability and longevity are crucial, and it handles operating temperatures up to 300C effectively.

FAQs of Rectangle Wire Mesh:

Q: How is Rectangle Wire Mesh typically used in various sectors?

A: Rectangle Wire Mesh is commonly employed in fencing, security applications, sieving processes, animal cage making, construction reinforcement, and agricultural tasks. Its strong, adaptable structure suits environments where reliable partitioning, protection, or filtration is needed.Q: What determines the open area percentage and how can it be customized?

A: The open area of Rectangle Wire Mesh depends on the aperture size and wire diameter. Larger apertures and thinner wires result in a higher open area, up to 70%. Both parameters can be customized to suit your specific requirements, optimizing airflow, visibility, or filtration.Q: When should I opt for reinforced or folded edge styles?

A: Reinforced or folded edges are recommended for applications requiring enhanced border strength, such as fencing or cages. They provide added durability and prevent fraying, making them ideal when the mesh will be exposed to physical stress or frequent handling.Q: Where is Rectangle Wire Mesh manufactured and supplied from?

A: Rectangle Wire Mesh is manufactured, exported, and supplied from India by experienced manufacturers, suppliers, and traders. Thanks to efficient logistics, orderswhether standard or customcan be fulfilled for domestic and international projects.Q: What is the minimum order quantity and can dimensions be customized?

A: The standard minimum order quantity is 100 square meters, though this can be negotiated. Dimensions such as length (typically 1030 meters per roll), width, aperture, wire gauge, and edge type can all be customized to match your project needs.Q: How does the choice of material affect corrosion resistance and temperature tolerance?

A: Stainless steel grades such as SS304 and SS316 offer superior corrosion resistance and can withstand temperatures up to 300C. Galvanized iron or low carbon steel options are also available, each with specific performance characteristics suited to various environments.Q: What are the benefits of surface treatments like polishing?

A: Polishing enhances the meshs surface by reducing roughness, improving appearance, and maximizing corrosion resistance. This treatment contributes to lower maintenance requirements and extends the meshs service lifespan, especially in exposed or harsh settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh Category

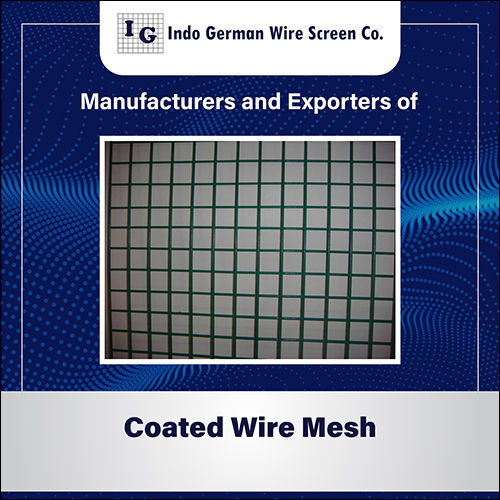

Coated Wire Mesh

Price Range 50.00 - 100.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Mesh Style : Welded Mesh

Material : Other, Low Carbon Steel

Product Type : Wire Mesh

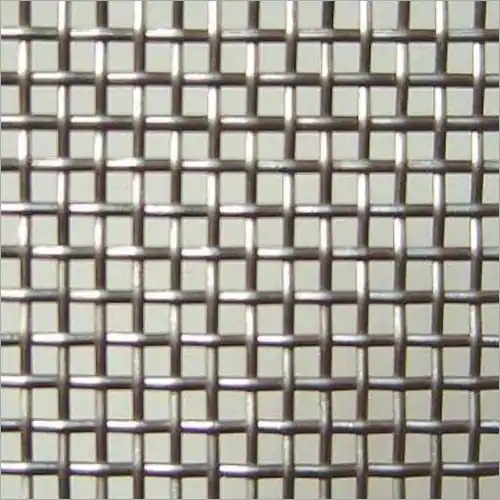

Metal Wire Mesh

Price Range 40.00 - 200.00 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Mesh Style : Plate Mesh

Material : Stainless Steel

Product Type : Wire Mesh

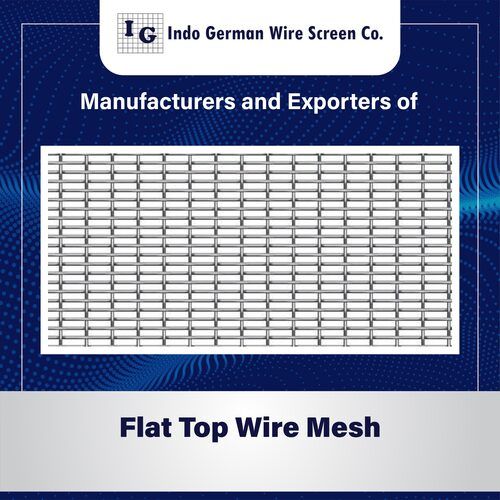

Flat Top Wire Mesh

Price 120 INR

Minimum Order Quantity : 10 Square Meters

Mesh Style : Other , Flat Top

Material : Steel

Product Type : Wire Mesh

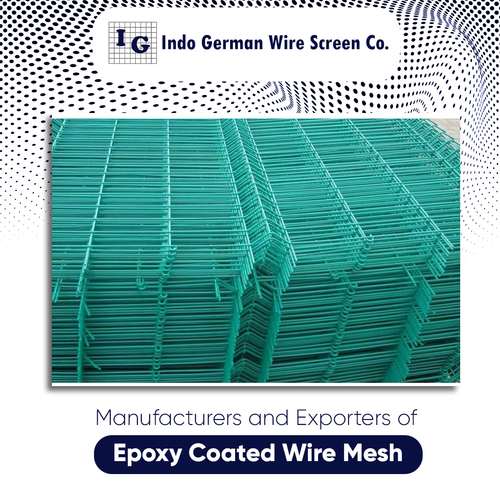

Epoxy Coated Wire Mesh

Price 14 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Mesh Style : Weave Wire Mesh

Material : Iron

Product Type : Wire Mesh

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry