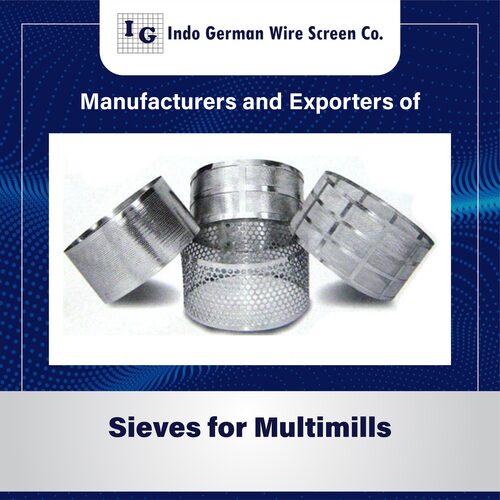

Multimill Sieves For Pharma

Price 1000 INR/ Foot

Multimill Sieves For Pharma Specification

- Surface Finish

- Mirror/Matte Polished

- Capacity

- Suitable for batch and continuous processing

- Temperature Resistance

- 200C max

- Cleaning Method

- Manual wash, ultrasonic cleaning or in-place washing

- Coating Type

- Non-coated/Plain Stainless Steel

- Set Contains

- Single sieve per pack

- Usage & Applications

- Pharmaceutical, Food, Chemical, and Cosmetics Industry

- Storage

- Store in dry area to prevent corrosion

- Heat Resistance

- Yes

- Product Type

- Multimill Sieves

- Material

- Stainless Steel

- Metal Type

- SS 316/SS 304

- Size

- Customizable (Standard diameters available: 250mm, 260mm, 300mm, etc.)

- Color

- Silver

- Weight

- Varies with size and mesh; typically 0.5 - 2 kg

- Thickness

- 0.5 mm to 2.0 mm (mesh and ring)

- Function

- Particle size reduction, granulation, and sieving in multi mill machines

- Sterilization

- Autoclavable

- Mesh Type

- Perforated or wire mesh

- Finish Type

- Electropolished edges for enhanced hygiene

- Corrosion Resistance

- Excellent due to high-grade stainless steel

- Compliance

- GMP and FDA standards

- Customization

- Mesh size, frame type, and diameter available on request

- Mesh Aperture

- Available from 0.2 mm to 25 mm

- Packaging

- Individually poly-wrapped and boxed

- Manufacturing Process

- Precision welded and calibrated

- Compatibility

- Compatible with all standard multimill machines

- Edge Type

- Plain/Beaded/Customized as per machine fitment

Multimill Sieves For Pharma Trade Information

- Minimum Order Quantity

- 50 Feet

- FOB Port

- mumbai

- Payment Terms

- Paypal, Letter of Credit at Sight (Sight L/C), Cash Advance (CA), Cash in Advance (CID)

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Multimill Sieves For Pharma

We offer the high quality of Multi Mills sieves for Pharma industry to our client. Multi mill Sieves are used for de-agglomeration, sizing, milling & sometimes also for granulation.These Multimill Sieves are offered in both standard and customized designed and are available in Plain weave, Dutch Weave, Twill weave with customised specification of mesh size and wire diameter.

Precision Engineering for Pharma Sieving

Designed to meet the stringent demands of pharmaceutical applications, our multimill sieves offer precise mesh apertures, ranging from 0.2 mm to 25 mm. The precision welded and calibrated manufacturing process ensures uniformity in particle size reduction, vital for quality control in granulation and sieving operations.

Superior Hygiene and Compliance

With GMP and FDA compliance, autoclavable construction, and electropolished edges, these sieves prioritize hygiene and safety. The mirror or matte polished surface allows for easy cleaning using manual, in-place, or ultrasonic methods, reducing contamination risks during processing.

Customizable for Diverse Applications

Our sieves can be tailored to your requirements, including mesh size, frame type, diameter, and edge finishing. Suitable for pharmaceutical, food, chemical, and cosmetic industries, they are compatible with all standard multimill machines and support both batch and continuous production processes.

FAQs of Multimill Sieves For Pharma:

Q: How do multimill sieves contribute to particle size reduction and granulation in pharmaceutical processing?

A: Multimill sieves facilitate particle size reduction and granulation by providing controlled mesh apertures that ensure consistent output of granular material. The precision-calibrated mesh regulates the size of particles, helping to maintain product quality during processing in multi mill machines.Q: What material and finish are used to ensure hygiene and corrosion resistance in these sieves?

A: These sieves are made from high-grade stainless steel (SS 304/316) and feature electropolished edges with mirror or matte surface finish. This combination provides excellent corrosion resistance and easy cleanability, meeting GMP and FDA hygiene requirements.Q: When should I sterilize the multimill sieves, and what sterilization methods are recommended?

A: Its best to sterilize multimill sieves before each use and after every batch to maintain aseptic conditions. The sieves are autoclavable and can also be cleaned by manual washing, ultrasonic cleaning, or in-place washing, depending on your facilitys protocols.Q: Where can these sieves be used, and what industries are they suitable for?

A: These multimill sieves are compatible with all standard multimill machines and can be used in pharmaceutical, food, chemical, and cosmetics industries for batch or continuous processing, whenever precise particle size control is required.Q: What customization options are available for mesh size, frame type, and diameter?

A: Mesh size (0.2 mm to 25 mm), frame type, sieve diameter (standard options: 250mm, 260mm, 300mm), and edge style (plain, beaded, or custom) can be tailored to fit specific machine requirements and processing needs. Custom requests are welcome to ensure optimal performance.Q: How does the packaging and storage of multimill sieves ensure product integrity?

A: Each sieve is individually poly-wrapped and boxed to protect against damage and contamination during transit and storage. For optimal longevity, store sieves in a dry area to minimize the risk of corrosion.Q: What are the benefits of using electropolished, autoclavable multimill sieves in pharma environments?

A: Electropolished, autoclavable sieves offer smoother edges and surfaces, reducing microbial adhesion and residue buildup. This ensures high hygiene standards, easier cleaning, and compliance with industry regulations, improving batch integrity and facilitating regulatory approval.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sifter Sieves Category

Multi Mill Sieves

Price Range 1200.00 - 5000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Metal

Color : Silver

Product Type : Multi Mill Sieves

Size : 50 microns to 20 mm

Test Sieves

Price Range 1750.00 - 5500.00 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Copper

Color : Silver

Product Type : Test Sieves

Size : 20 40 inch

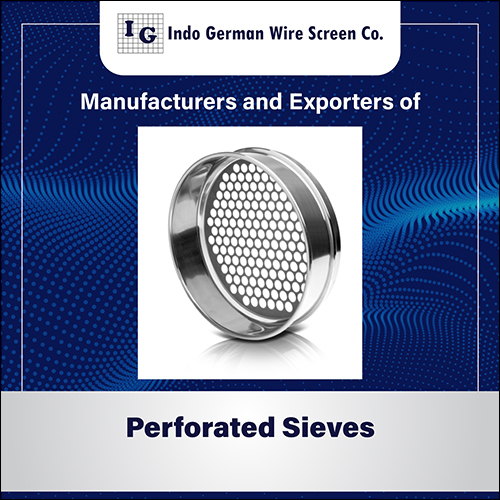

Perforated Sieves

Minimum Order Quantity : 1 Piece

Material : Aluminum

Color : Silver

Product Type : Perforated Sieves

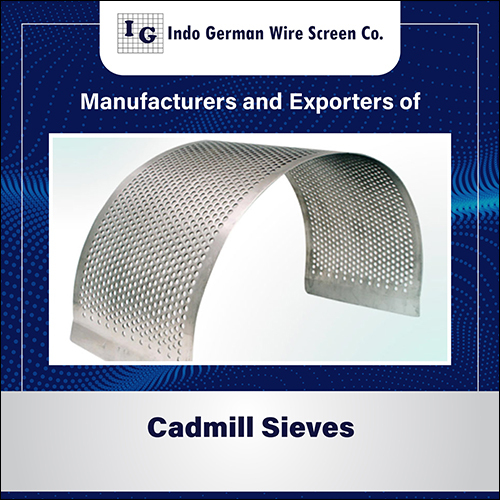

Cadmill Sieves

Price Range 1200.00 - 5000.00 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Others, Stainless Steel

Color : Sliver

Product Type : Cadmill Sieves

Size : 52 Mm x 542 Mm

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry