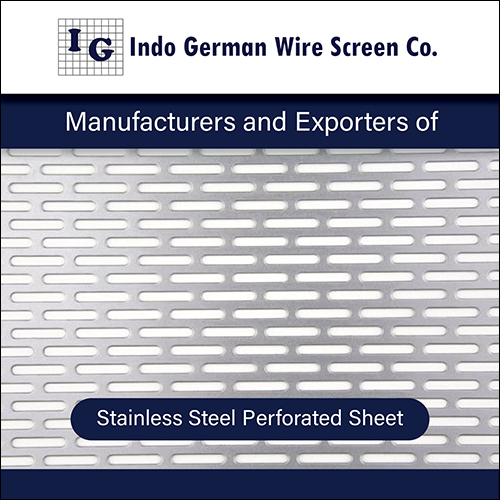

Stainless Steel Perforated Sheet

Stainless Steel Perforated Sheet Specification

- Surface Treatment

- Plating

- Shape

- Rectangular

- Usage

- industrial

- Material

- Stainless Steel

- Technique

- Perforated

- Product Type

- Perforated Sheet

- Thickness

- 0.5 - 8.00 Millimeter (mm)

Stainless Steel Perforated Sheet Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 100 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Stainless Steel Perforated Sheet

Based in Mumbai, we are manufacturing and supplying a wide range of Stainless Steel Perforated Sheet. To produce these perforations, it is manually or mechanically stamped. It is manufactured under the supervision of our experts by using high-grade raw materials and latest technologies. As it is built using stainless steel, thus it is resistant to corrosion and is rust free. Different types of equipment are used for perforation of metals including die, punch presses, laser perforation, and pinned perforation. Stainless Steel Perforated Sheet can be used in processing equipment, dairy, instruments and food, and beverage product handling.

Special Features ofStainless Steel Perforated Sheet:

- Notable for the rectangular hole pattern

- Ideal for indoor acoustic jobs, mining, grain storage, and ventilation purpose

- Uniform and flat surface with durable structure, low maintenance design, long-lasting quality

- Stamping weaving technology and accessibility in the standard thickness range

Product details

|

Hole Shape |

Round |

|

Technique |

Perforated |

|

Material |

Stainless steel |

Precision Manufacturing for Optimal Quality

We utilize advanced perforation techniques and surface plating to guarantee each stainless steel sheet meets exacting industrial standards. Our meticulous attention to detail ensures smooth edges and consistent perforations, making them suitable for demanding industrial environments.

Versatile Industrial Applications

These perforated sheets are engineered for versatility, supporting applications such as filtration, ventilation, soundproofing, and protective screening across various industries. Their robust construction ensures longevity and adaptable performance in numerous operational settings.

FAQs of Stainless Steel Perforated Sheet:

Q: How are stainless steel perforated sheets manufactured?

A: Our stainless steel perforated sheets are produced using advanced perforation machinery that punches precise holes into rectangular sheets, followed by surface plating to enhance durability and corrosion resistance.Q: What industrial applications can use these perforated sheets?

A: These sheets are widely used in filtration, ventilation systems, screening, acoustic panels, and protective covers across industries such as chemical processing, food, pharmaceuticals, and architecture.Q: When should I choose a perforated sheet with a specific thickness?

A: The choice of thicknessfrom 0.5 to 8.00 mmdepends on your applications strength requirements. Thinner sheets are suitable for filtration and decorative purposes, while thicker sheets are preferred for load-bearing or protective applications.Q: Where are your stainless steel perforated sheets supplied from?

A: We operate as an exporter, manufacturer, supplier, and trader based in India, supplying high-quality stainless steel perforated sheets to clients nationwide and in international markets.Q: What is the process for ordering customized perforated sheets?

A: You can contact us with your specific requirements for size, thickness, hole pattern, and quantity. Our team will guide you through the customization and ordering process to ensure we meet your industrial needs.Q: How does surface plating benefit stainless steel perforated sheets?

A: Surface plating provides an added layer of protection against corrosion, extending the lifespan of the sheets, maintaining their appearance, and ensuring reliable performance in harsh industrial environments.Q: What are the main advantages of using stainless steel perforated sheets?

A: The primary benefits include excellent corrosion resistance, mechanical strength, versatility in design, and a long service life, making them a smart choice for diverse and demanding industrial usages.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

Sifter Sieves For Granules

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Technique : Other, Perforated/ Woven Mesh fabrication

Usage : industrial

Application : Sieving and grading of granules in industrial processes

Sifter Sieves For Vibro Screen

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet, ,

Technique : Other, Perforated/ Woven mesh fabrication

Usage : industrial

Application : Screening, Grading, Sifting, Filtering in food, pharmaceutical, chemical and mining industries

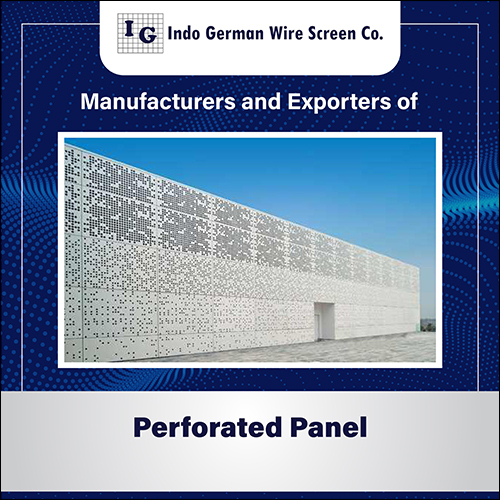

Perforated Panel

Price 85 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Technique : Perforated

Usage : industrial

Application : For Industrial

Perforated Coils

Price Range 50.00 - 200.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Technique : Perforated

Usage : industrial

Application : For Industrial

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry