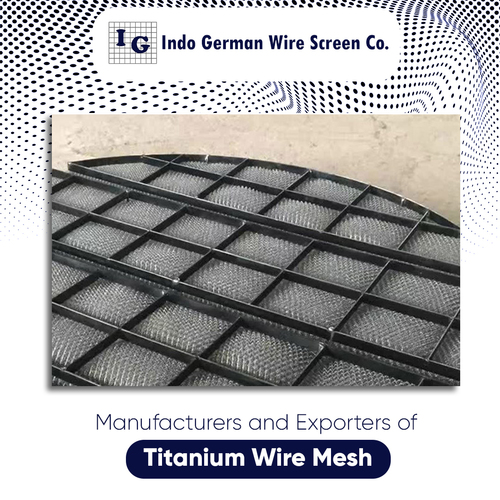

Titanium Wire Mesh

Titanium Wire Mesh Specification

- Hole Shape

- Square / Rectangular

- Length

- 20 m / 30 m rolls or as required

- Surface Treatment

- Annealed / Pickled / Polished

- Wire Gauge

- 10-100 SWG

- Aperture

- 0.1 mm - 10 mm

- Product Type

- Wire Mesh

- Mesh Type

- Steel Wire Mesh

- Mesh Style

- Woven Mesh

- Material

- Steel

- Alloy

- Pure Titanium (Gr1/Gr2)/Titanium Alloy (Gr5 Ti-6Al-4V)

- Application

- Filtration, Chemical Processing, Marine, Aerospace, Medical, Industrial Separation

- Dimensions

- Customizable / Standard: 1 m x 30 m roll

- Wire Diameter

- 0.05 mm - 1.2 mm

- Weight

- Lightweight, varies with specification

- Color

- Sliver

Titanium Wire Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Meter Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Titanium Wire Mesh

We are highly engaged to provide a quality approved assortment of Titanium Wire Mesh that is used in aerospace and medical industry. Our offered wire mesh is valued for its light weight, high strength and corrosion-resistant properties. These wire mesh is available in different variety of specifications as per the varied demands of our valuable customers. Offered wire mesh is manufactured using high quality titanium material and contemporary technology. Also, the quality of this Titanium Wire Mesh is stringently tested by our quality checkers against different parameters.

Specifications of Titanium Wire mesh

- Material grade: TA1, TA2 GR1, GR2, R50250.

- Weaving type: Plain Weave, Twill Weave and Dutch Weave.

- Wire diameter: 0.002" - 0.035".

- Mesh size: 4 mesh - 150 mesh.

- Colour: black or bright.

Premium Quality & Standards

Our Titanium Wire Mesh is manufactured to strict ASTM F67 and F136 standards, ensuring reliable mechanical strength and longevity. Available in both pure and alloyed grades, it delivers exceptional quality for industries such as filtration, aerospace, and marine applications.

Customization & Versatility

Offering a broad selection of mesh openings, aperture sizes, and roll dimensions, the mesh is crafted to suit various requirements. Customization is available, allowing users to specify wire diameter, mesh size, and length according to unique operational needs.

Applications & Benefits

This wire mesh is widely used in filtration, chemical processing, medical devices, marine engineering, and industrial separation due to its lightweight structure and extraordinary corrosion resistance. Its high tensile strength and temperature tolerance facilitate secure, long-term performance in harsh environments.

FAQs of Titanium Wire Mesh:

Q: How is Titanium Wire Mesh typically used across industries?

A: Titanium Wire Mesh is widely used for filtration, chemical processing, marine engineering, aerospace applications, medical implants, and industrial separation. Its robust corrosion resistance and durability make it suitable for harsh environments where acids, alkalis, or salt water are present.Q: What benefits does a tensile strength of 240 MPa offer for this mesh?

A: A minimum tensile strength of 240 MPa ensures that the mesh maintains its structural integrity under mechanical stress, allowing for secure, long-term use in critical engineering and filtration applications even at high temperatures up to 600C.Q: When should I choose pure titanium versus titanium alloy grades?

A: Pure titanium (Gr1/Gr2) is optimal for maximum corrosion resistance, especially in chemical or marine environments. Titanium alloy (Gr5 Ti-6Al-4V) should be selected when higher strength or performance at elevated temperatures is required.Q: Where can this mesh be installed, and what are the typical dimensions?

A: The mesh can be installed in filtration systems, chemical reactor vessels, marine equipment, and medical devices. Standard roll sizes are 1 m x 30 m, with customized options available for length, width (0.5 m to 2 m), aperture (0.1 mm - 10 mm), and mesh size (80 mesh to 0.5 mesh).Q: What process ensures the meshs corrosion resistance and finish?

A: The mesh undergoes surface treatments such as annealing, pickling, or polishing, which enhance its resistance to corrosion and deliver a clean, uniform appearance. These processes also improve durability in aggressive chemical environments.Q: How is the mesh packaged for safe delivery?

A: Titanium Wire Mesh is securely packed using waterproof paper, wooden cases, or pallets to preserve quality and prevent damage during transportation, especially for international shipments from India.Q: What is the advantage of customizable opening sizes and wire diameters?

A: Customizable openings (from 80 mesh to 0.5 mesh) and wire diameters (0.05 mm to 1.2 mm) allow users to tailor the mesh for precise filtration, separation, or reinforcement purposes, optimizing performance for specific operational requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

Tungsten Wire Mesh

Price 45 INR

Minimum Order Quantity : 10 Square Foots

Color : Sliver

Mesh Type : Steel Wire Mesh

Application : Other, Sieving, filtration, high temperature applications, chemical processing

Stainless Steel 309 Wire Mesh

Price Range 220.00 - 750.00 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Color : Sliver

Mesh Type : Steel Wire Mesh

Application : Other, Filtration, Construction, Chemical Processing, Heat Resistant Applications

Molybdenum Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver Gray

Mesh Type : Other , Metal Mesh

Application : Other, Hightemperature furnace, filtration, aerospace, electronics

Inconel 601 Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Metallic grey

Mesh Type : Other , Fine / Coarse

Application : Other, High temperature filtration, furnace liners, chemical processing, heat treatment

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry