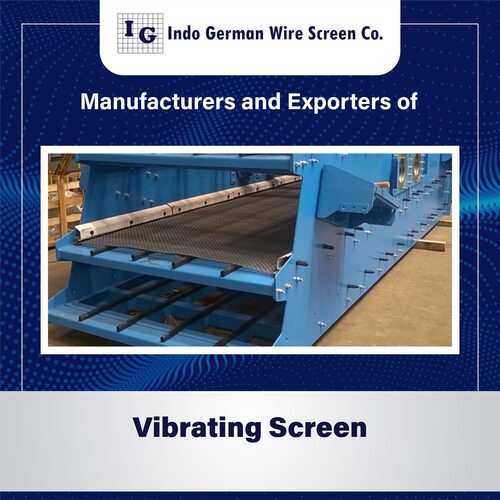

Vibrating Screen

Price 180 INR/ Square Foot

Vibrating Screen Specification

- Type

- Vibrating Screen

- Material

- Stainless Steel

- Processing Type

- Standard

- Shape

- Spiral

- Application

- stone crusher, industrial purpose, vibrator

Vibrating Screen Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Vibrating Screen

Since our establishment in 1996, we are the most effective manufacturer and supplier of excellent quality range of Vibrating Screen. In accordance with predefined market standards, this screen is properly designed by utilizing finest quality materials under the guidance of our experts. Available in several designs and dimensions, these screens are demanded for fastening with several equipments and machines to minimize uneven vibrations. Our clients can easily avail this Vibrating Screen from us at the best market price.

Features of Vibrating Screen:

- Fine finish

- Durable quality

- Rust resistant

Product Details

|

Material Grade |

Spring Steel, High carbon steel. |

|

Usage |

Industrial,Agricultural,Defence |

|

Size |

Customize |

Engineered for Stone Crushing and Industrial Demands

Our vibrating screen is specifically engineered for challenging stone crusher operations and diverse industrial applications. Its spiral design, coupled with stainless steel construction, ensures both efficiency and longevity, enduring the rigors of continuous processing in Indian manufacturing settings.

Versatile Applications and Superior Export Quality

Whether you are a manufacturer, supplier, or trader, this vibrating screen caters to a variety of processing needs. Trusted for exporting, its robust build and performance meet international standards. Businesses across India rely on its versatility, adapting seamlessly to different industrial screening processes.

FAQs of Vibrating Screen:

Q: How does the spiral-shaped stainless steel vibrating screen function in stone crushing operations?

A: The spiral-shaped vibrating screen uses high-frequency vibration to move crushed stones across the screen, efficiently separating particles by size. Its stainless steel construction offers superior durability, making it ideal for continuous stone crusher use.Q: What industries commonly benefit from using this vibrating screen?

A: Industries involved in stone crushing, mining, construction, pharmaceuticals, chemical production, and other large-scale industrial operations frequently utilize this vibrating screen due to its efficiency in sorting and processing a variety of materials.Q: When should the vibrating screen be used in the stone processing workflow?

A: The vibrating screen is typically used after primary and secondary crushing. It is positioned to classify, separate, and filter the processed materials before they move to subsequent stages or packing, ensuring material consistency and quality control.Q: Where can I source this vibrating screen in India?

A: You can obtain this vibrating screen from reputable manufacturers, suppliers, exporters, and traders across India. Most major industrial equipment hubs and specialized export companies offer this product with installation and service support.Q: What is the operational process of this standard-type vibrating screen?

A: The process begins by feeding raw or crushed material onto the vibrating screen. Vibration causes the material to travel along the spiral-shaped surface, where particles are sorted and separated based on size and weight, leading to efficient material classification.Q: How is the vibrating screen beneficial for exporters and manufacturers?

A: The robust stainless steel construction ensures longevity and reliability, minimizing maintenance costs. For exporters and manufacturers, this means consistent product quality, efficient processing, and compliance with Indian and international standards, enhancing business competitiveness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibrating Screen Category

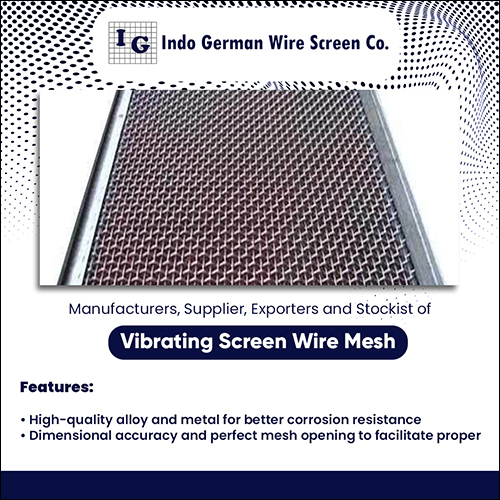

Vibrating Screen Mesh

Price 185 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Application : For Industrial

Material : Stainless Steel

Media : Vibrating Mesh

Shape : Spiral

Circular Screen

Minimum Order Quantity : 1 , , Piece

Application : stone crusher, industrial purpose, vibrator

Material : Other, spring steel, high carbon steel.

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry