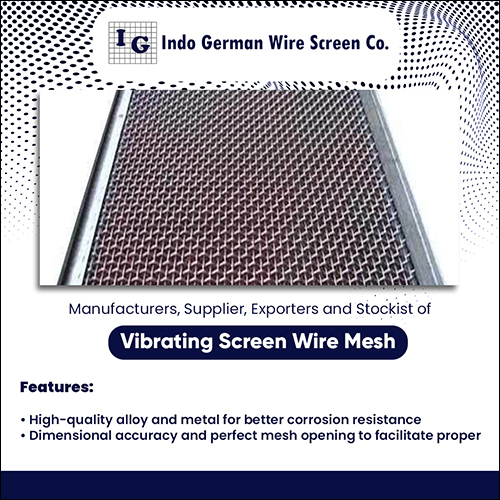

Vibrating Screen Mesh

Price 185 INR/ Square Foot

Vibrating Screen Mesh Specification

- Type

- Vibrating Screen

- Material

- Stainless Steel

- Processing Type

- Woven Mesh

- Condition

- New

- Shape

- Spiral

- Capacity

- Depend on mesh size

- Diameter

- Customized

- Layer

- Single or Multiple Layer

- Dimension (L*W*H)

- Customizable

- Power Mode

- Manual

- Media

- Vibrating Mesh

- Noise Level

- Low

- Frequency

- 50-60 Hz

- Application

- For Industrial

- Coating Type

- Galvanized / Polished

- Color

- Silver

- Surface Finish

- Smooth, Corrosion Resistant

- Tensile Strength

- High

- Usage

- Screening, Sieving, Filtering

- Opening Size

- 0.5 mm to 150 mm (custom available)

- Corrosion Resistance

- Yes

- Wire Diameter

- 0.5 mm to 12 mm

- Edge Preparation

- Clamped, Hooked, or As Specified

- Durability

- High

- Mesh Size

- As per requirement

Vibrating Screen Mesh Trade Information

- Minimum Order Quantity

- 10 Square Foots

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Square Foots Per Day

- Delivery Time

- 1 Week

- Packaging Details

- Carton Box

- Main Domestic Market

- All India

About Vibrating Screen Mesh

With knowledge and expertise, we have become an expert manufacturer, importer, trader, exporter and supplier of Vibrating Screen Mesh that is widely used for screening of all fibers containing impurities. The offered screen is hugely demanded by our adorned customers as it removes large impurities such as plastics, metal particles, film, wooden spiders, etc. This screen is manufactured using premium quality raw materials and hi-tech machinery under the supervision of our talented professionals in conformity with set market prevailing standards. In addition to this, we provide this Vibrating Screen Mesh in various sizes and dimensions at discounted prices.

Features of Vibrating Screen Mesh:

- Optimum strength

- Weather resistance

- Perfect finish

- Rust proof

Product Details

| Material | Stainless Steel |

| Material Grade | SS 304, 316 |

| Hole Shape | Square,Circular |

| Usage | Industrial |

Precision as You Need It

Our vibrating screen mesh is available with customizable opening sizes and wire diameters, offering flexibility for various screening, sieving, and filtering operations. Whether your application demands fine separation or coarse grading, our mesh ensures optimal results tailored to your industrial processes.

Engineered for Durability

Manufactured from premium stainless steel, this mesh is corrosion-resistant and built to withstand demanding industrial conditions. The high tensile strength and robust surface finish minimize maintenance needs while maximizing long-term operational efficiency and durability, even in harsh environments.

Versatile Application

Suitable for a range of industries, our vibrating screen mesh can be supplied with single or multiple layers, clamped or hooked edges, and in a spiral shape. Its adaptability makes it ideal for mineral processing, food handling, chemical filtration, and more, supporting both manual and automated screening processes.

FAQs of Vibrating Screen Mesh:

Q: How is the opening size of the vibrating screen mesh customized?

A: The opening size can be specified anywhere from 0.5 mm to 150 mm, allowing you to select the ideal mesh dimensions for your particular screening, sieving, or filtering application. Customization ensures precise separation according to your process requirements.Q: What material is used for manufacturing the vibrating screen mesh, and how does it benefit industrial use?

A: Our vibrating screen mesh is made from high-quality stainless steel, offering excellent corrosion resistance, enhanced durability, and a smooth surface. This makes it suitable for industries where moisture, abrasion, or chemical exposure is frequent.Q: Where can the vibrating screen mesh be installed?

A: It is designed for use in a variety of industrial settings, including mineral processing plants, food processing units, chemical industries, and other sectors requiring sieving or filtering. Its adaptability allows integration with manual or mechanical vibrating screen equipment.Q: When should clamped, hooked, or custom edge preparation be considered?

A: Edge preparation depends on the installation method and equipment. Clamped edges are commonly used for easy installation and replacement, while hooked edges are ideal for securing mesh on vibrating screens. Custom preparations are available for unique or specialized machinery.Q: What is the process of ordering a customized vibrating screen mesh?

A: To order a customized mesh, specify your required opening size, wire diameter, shape (spiral), edge style, and desired layer (single or multiple). As an exporter, manufacturer, supplier, and trader in India, we ensure your mesh is engineered precisely to meet your operational needs.Q: How does the vibrating screen mesh provide high durability and low maintenance?

A: With a galvanized or polished coating and stainless steel construction, the mesh resists corrosion and wear even under continuous use. High tensile strength reduces the risk of tears or deformation, ensuring longevity and minimizing downtime or replacements.Q: What are the advantages of using a vibrating screen mesh in industrial applications?

A: The mesh offers efficient screening, precise separation, high durability, and enhanced corrosion resistance. Its customizable features and robust construction contribute to superior performance, reduced maintenance costs, and versatility across numerous industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

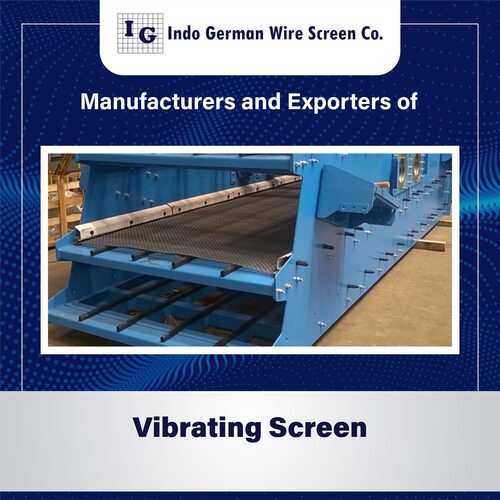

More Products in Vibrating Screen Category

Vibrating Screen

Price 180 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Application : stone crusher, industrial purpose, vibrator

Material : Stainless Steel

Processing Type : Standard

Type : Other, Vibrating Screen

Circular Screen

Minimum Order Quantity : 1 , , Piece

Application : stone crusher, industrial purpose, vibrator

Material : Other, spring steel, high carbon steel.

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry