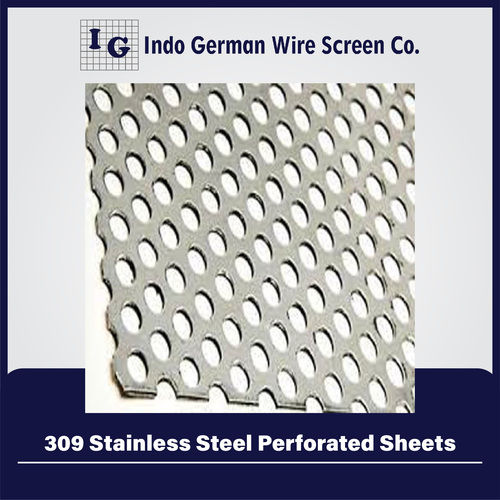

309 Stainless Steel Perforated Sheets

Price 50 INR/ Unit

309 Stainless Steel Perforated Sheets Specification

- Standard

- ASTM A240 / A240M, JIS, DIN

- Temper

- Soft, Hard, Half Hard

- Shape

- Rectangular, Square, Custom Shapes

- Surface Treatment

- Polished, Pickled, Annealed

- Process

- Perforating, Cutting, Forming

- Material

- 309 Stainless Steel

- Type

- Perforated Sheet

- Technique

- Cold Rolled / Hot Rolled

- Thickness

- 0.5 mm to 6 mm

- Application

- Chemical Industry, Petrochemical, Filtration, Architectural Applications, Food Processing, Power Plants

- Feature

- High Temperature Resistance, Corrosion Resistant, Durable, High Strength

- Sheet Size

- 1000 mm x 2000 mm, 1220 mm x 2440 mm, Custom Sizes

- Density

- 8.0 g/cm³

- Melting Point

- 1398 - 1454°C

- Tensile Strength

- 515 MPa (min)

- Hole Shape

- Round, Square, Slotted, Decorative

- Finish

- 2B, BA, No.4, Mirror

- Edge Type

- Mill, Slit, Sheared

- Elongation

- 40% (min)

- Yield Strength

- 205 MPa (min)

- Open Area

- 10% to 60% (depending on perforation pattern)

- Hole Size

- 0.5 mm to 25 mm

- Weldability

- Excellent

About 309 Stainless Steel Perforated Sheets

309 Stainless Steel grades have properties like easy formability, manufacturability, corrosion resistance, fire and heat resistance. 309 Stainless Steel grades have high tensile strength, temperature resistance, impact resistance, and excellent strength-to-weight ratio. 309 Stainless Steel grade have features like attractive appearance and high cleanability, low-maintenance, durable material, and environmentally friendly (recyclable). Stainless Steel has properties like easy formability, manufacturability, corrosion resistant, fire and heat resistance. Stainless Steel has these characteristics, in combination with usually low cost, greater sustainability, and superior aesthetic appearance, have led it becoming one of the most extensively used construction materials across a varied set of industries.Indo German Wire Screen Co. has the in-house fabrication capabilities to provide custom perforated hole patterns for unique or specialty applications, if required.

We offer an exclusive range of 309 Stainless Steel Perforated Sheets at unmatched quality and market leading prices.

Versatile Perforation Patterns

Choose from a wide selection of perforation patternsincluding round, square, slotted, and decorative shapesto achieve optimal airflow, filtration, or aesthetic appeal in your application. The open area can be customized from 10% to 60%, providing flexibility for both functional and design needs.

Durable and High-Strength Performance

309 stainless steel offers superior yield and tensile strength, with excellent elongation and robust corrosion resistance. Its exceptional durability under high temperatures and harsh environments makes it ideal for chemical processing, power plants, and heavy-duty filtration systems.

Customizable Sizes and Finishes

Sheets are available in standard sizes as well as customized dimensions, with thickness options from 0.5 mm to 6 mm. Multiple edge types (mill, slit, sheared) and finishes (2B, BA, No.4, Mirror) cater to specific project requirements, ensuring both functional and visual excellence.

FAQs of 309 Stainless Steel Perforated Sheets:

Q: How are 309 stainless steel perforated sheets manufactured?

A: These sheets are produced through cold or hot rolling, followed by perforating, cutting, and forming processes. The holes are made using precision techniques to achieve the desired shape and open area, and the sheets may undergo surface treatments like polishing, pickling, or annealing for enhanced properties.Q: What applications are suitable for 309 stainless steel perforated sheets?

A: 309 stainless steel perforated sheets are widely used in chemical and petrochemical industries, filtration systems, architectural installations, food processing, and power plants due to their corrosion resistance, high temperature tolerance, and mechanical strength.Q: When should I select a specific perforation pattern for my project?

A: The choice of pattern depends on your applications airflow, filtration, visibility, and aesthetic needs. For maximum ventilation or drainage, higher open area patterns like round or slotted holes are suitable, while square or decorative shapes can be chosen for visual or specific functional requirements.Q: Where can I request custom sizes or shapes for these perforated sheets?

A: Custom sizes and shapes are available directly from exporters, manufacturers, suppliers, and traders in India who specialize in 309 stainless steel perforated sheets. They can tailor dimensions, hole configurations, and finishes to align with your project specifications.Q: What surface treatments and finishes are available for these sheets?

A: 309 stainless steel perforated sheets can be finished with options like 2B, BA, No.4, or Mirror finishes. Additional treatments include polishing, pickling, and annealing to improve surface quality, corrosion resistance, and appearance depending on the intended application.Q: How do these sheets benefit high temperature and corrosive environments?

A: With a melting point between 13981454C and excellent chemical resistance, 309 stainless steel perforated sheets maintain structural integrity and resist degradation. Their robust physical properties ensure long service life in extreme operating conditions.Q: What standards do these sheets comply with?

A: 309 stainless steel perforated sheets adhere to international standards including ASTM A240/A240M, JIS, and DIN, ensuring consistent quality and reliable performance across diverse industrial and architectural applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Perforated Sheet Category

316 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Epoxy Coated, Matte or Bright Finish

Material : Other , 316 Stainless Steel

347 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Mill Finish

Material : Other , 347 Stainless Steel

430 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Other , Polished, Matte, or as required

Material : Other , 430 Stainless Steel

304 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Surface Treatment : Powder Coated

Material : Stainless Steel

Size : Standard

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry