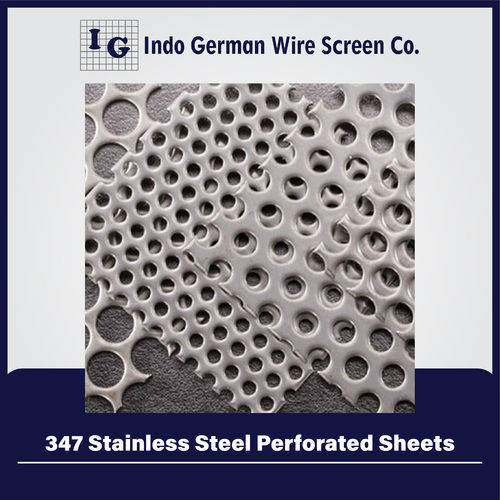

347 Stainless Steel Perforated Sheets

Price 50 INR/ Unit

347 Stainless Steel Perforated Sheets Specification

- Process

- Perforation, Punching

- Surface Treatment

- Polished, Mill Finish

- Shape

- Rectangular, Square, Custom Sizes

- Temper

- Soft, Hard, Half Hard

- Standard

- ASTM A240, ASME SA240

- Material

- 347 Stainless Steel

- Type

- Perforated Sheet

- Technique

- Cold Rolled, Hot Rolled

- Thickness

- 0.5 mm to 10 mm

- Application

- Chemical Processing, Food Industry, Power Generation, Petrochemical, Heat Exchangers

- Feature

- Corrosion Resistant, High Temperature Strength, Excellent Weldability, Durability

About 347 Stainless Steel Perforated Sheets

Stainless Steel 347 Grade is niobium-stabilized austenitic stainless steel. Stainless Steel 347 Grade has higher creep and stress rupture properties than grade 304 and better corrosion resistance and provides oxidation resistance marginally better than grade 321. Stainless Steel has properties like easy formability, manufacturability, corrosion resistant, fire and heat resistance. Stainless Steel has high tensile strength, temperature resistance, impact resistance, and excellent strength-to-weight ratio. Stainless Steel has these characteristics, in combination with usually low cost, greater sustainability, and superior aesthetic appearance, have led it becoming one of the most extensively used construction materials across a varied set of industries.347 Stainless Steel Perforated Sheets fences and banisters keep enclosed machines and other properties from damage secure and the safety of people. Indo German Wire Screen Co. has the in-house fabrication capabilities to provide custom perforated hole patterns for unique or specialty applications, if required.

Versatile Hole Designs & Customization

Choose from round, square, slotted, or tailor-made perforations to meet your exact project requirements. With hole sizes ranging from 0.5 mm to 20 mm and open areas up to 70%, these sheets are engineered for optimal airflow, filtration, or aesthetics in intricate applications.

Superior Mechanical and Thermal Properties

The 347 stainless steel material offers minimum yield strength of 205 MPa, tensile strength of 515 MPa, and elongation of at least 40%, ensuring structural integrity. Heat resistance up to 870C (1600F) makes these sheets ideal for demanding environments where both durability and performance are vital.

Flexible Dimensions and Surface Finishes

Sheets are available in widths from 500 mm to 1500 mm and lengths from 1000 mm to 3000 mm. Select from various finishes including 2B, BA, matt, or glossy, and edge types such as mill or slit, enabling suitable integration into diverse industrial and architectural applications.

FAQs of 347 Stainless Steel Perforated Sheets:

Q: How are 347 Stainless Steel Perforated Sheets manufactured?

A: These sheets are produced using cold rolled or hot rolled techniques, followed by perforation and punching processes as specified by ASTM A240 or ASME SA240 standards. Surface treatments such as polishing or mill finish are applied for added durability and aesthetic appeal.Q: What are the benefits of using 347 Stainless Steel Perforated Sheets in high-temperature applications?

A: With excellent heat resistance up to 870C (1600F), these sheets maintain structural integrity and corrosion resistance, making them reliable for power generation, petrochemical, and heat exchanger environments.Q: Where can these perforated sheets be used effectively?

A: 347 Stainless Steel Perforated Sheets are widely utilized in chemical processing, the food industry, power generation plants, petrochemicals, and heat exchangers due to their durability, hygiene, and adaptability.Q: What size and shape options are available for holes in these sheets?

A: Various hole shapes including round, square, slotted, and custom designs are available, with sizes ranging from 0.5 mm to 20 mm and open areas up to 70%, allowing for precise control over filtration, ventilation, and appearance.Q: How is the weldability of 347 Stainless Steel Perforated Sheets?

A: These sheets exhibit excellent weldability, enabling secure joining during installation or fabrication, which is essential for complex industrial applications where reliable seams are required.Q: When should I choose custom sizes or shapes for perforated sheets?

A: Opt for custom sizes or shapes when your project demands non-standard dimensions or specialized hole patterns to optimize performance, aesthetics, or integration with existing systems.Q: What packing and shipping standards are followed for these sheets?

A: All sheets are packed using standard export packing practices to prevent damage during transit and storage, ensuring they arrive ready for immediate use on-site.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Perforated Sheet Category

330 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 330 Stainless Steel

Surface Treatment : Other , Polished, Matt Finish

Shape : Rectangular, Square, Customizable

Process : Perforating, Cutting, Punching

309 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 309 Stainless Steel

Surface Treatment : Other , Polished, Pickled, Annealed

Shape : Rectangular, Square, Custom Shapes

Process : Perforating, Cutting, Forming

430 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 430 Stainless Steel

Surface Treatment : Other , Polished, Matte, or as required

Shape : Rectangular, Can be customized

Process : Perforation by mechanical stamping or punching

321 Stainless Steel Perforated Sheets

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Other , 321 Stainless Steel

Surface Treatment : Other , Polished, Mill finish

Shape : Sheet (rectangular and square available)

Process : Punching / Perforation

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry