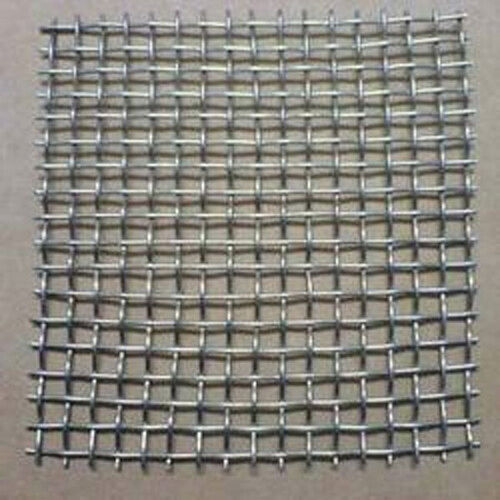

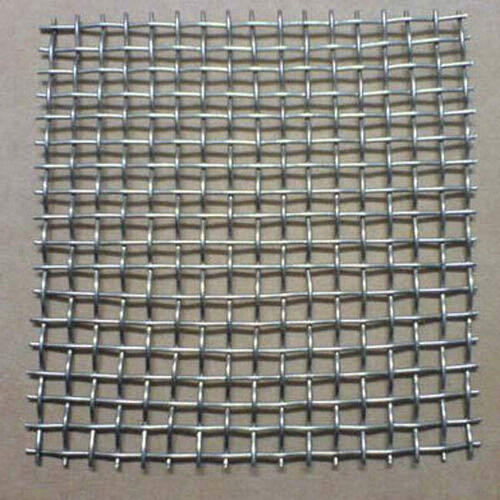

309 Stainless Steel Welded Wire Mesh

Price 50 INR/ Unit

309 Stainless Steel Welded Wire Mesh Specification

- Surface Treatment

- Coated

- Wire Gauge

- 14 SWG

- Length

- 30 m

- Aperture

- 25.4 mm

- Hole Shape

- Square

- Product Type

- Wire Mesh

- Mesh Type

- Welded

- Mesh Style

- Welded Mesh

- Material

- Stainless Steel

- Alloy

- 309

- Application

- Other

- Dimensions

- Custom sizes available

- Wire Diameter

- 2.0 mm

- Weight

- Variable based on size

- Color

- Gray

309 Stainless Steel Welded Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5000 Units Per Month

- Delivery Time

- 7 Days

About 309 Stainless Steel Welded Wire Mesh

309 Stainless Steel Welded Wire Meshprovides the most resistive railings as it wears resistivity of heat, acid, and corrosions, etc.309 Stainless Steel Welded Wire Meshhigh resistance makes its applications in a wide range such as chemical industries, mining areas, food industries, and pharmaceutical industries.We offer an exclusive range of 309 Stainless Steel Welded Wire Mesh at unmatched quality and market leading prices.

Indo German Wire Screen Co., we are the professional people delivering high-quality and superior-performance products that have been appreciated by all of our previous customers.These high-quality products are manufactured at our premises using quality tested raw materials and components according to industry quality standards.

Exceptional Heat and Corrosion Resistance

Made from 309 stainless steel, this welded wire mesh is specifically designed to excel in high-temperature environments, sustaining operations at up to 1000C. With a smooth, coated surface and excellent corrosion resistance, it is reliable for industrial filtration, construction, and demanding heat barrier applications.

Precision Manufacturing and Quality Standards

Manufactured using automated welding machinery, each roll adheres to ASTM A580/A580M standards, assuring consistent structure and tensile strength. The smooth finish and plain edge add to its safety and ease of installation, supporting long-lasting performance in industrial settings.

Custom Sizes and Versatile Applications

Available in a standard roll width of 1 meter and length of 30 meters, the mesh also accommodates custom dimensions. Square apertures of 25.4 mm make it suitable for construction, filtration, and protective barrier uses, supporting diverse requirements across multiple industries.

FAQs of 309 Stainless Steel Welded Wire Mesh:

Q: How is the 309 Stainless Steel Welded Wire Mesh manufactured?

A: The mesh is produced using automated welding machinery, ensuring strong and consistent welds at every intersection. This process enhances both strength and durability, meeting ASTM A580/A580M standards.Q: What industries typically benefit from using this welded wire mesh?

A: It is commonly used in industrial filtration, construction, and as heat-resistant barriers. The high corrosion resistance and heat tolerance make it ideal for environments requiring robust, long-term solutions.Q: When should I choose 309 stainless steel mesh over other types?

A: Opt for 309 stainless steel mesh when your application requires exposure to high temperatures (up to 1000C) or involves corrosive conditions, as it offers superior resistance compared to standard stainless steels.Q: Where can this mesh be installed?

A: This welded mesh can be installed in a variety of environments, including factories, construction sites, and any location that demands durable, high-temperature and corrosion-resistant barriers or filtration systems.Q: What mesh sizes and dimensions are available?

A: Standard rolls come in a 1-meter width, 30-meter length, 25.4 mm aperture, and 2.0 mm wire diameter, but custom sizes are available to meet specific project needs.Q: How does the coated surface treatment benefit the mesh?

A: The coated finish further enhances corrosion resistance and longevity, making the mesh particularly suitable for harsh or corrosive environments while preserving its smooth appearance and durability.Q: What are the main benefits of using this mesh in industrial applications?

A: The primary advantages are high tensile strength, excellent corrosion and heat resistance, adaptability to custom sizes, and compliance with strict ASTM standards, ensuring safety and reliability in demanding industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welded Wire Mesh Category

321 Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Welded Mesh

Color : Silver

410 Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Welded Mesh

Color : Gray

316 L Stainless Steel Welded Wire Mesh

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Wire Mesh

Mesh Style : Welded Mesh

Color : Gray

Wire Mesh Screen

Price Range 400.00 - 1000.00 INR / Foot

Minimum Order Quantity : 50 Feet

Product Type : Wire Mesh

Mesh Style : Welded Mesh

Color : Silver

|

INDO GERMAN WIRE SCREEN CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry